Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

29 |

| 30 |

|

|

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

390Likes 390Likes

09-23-2020, 09:16 PM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

Thanks Craig.

Because of registration compliance requirements here in South Australia, almost everything under the skin on my build differs from a 1960’s Cobra, hence the semi-monocoque “chassis” and the engine specs.

So which "power plant"? The engine is a 302, originally factory-built by Tickford. It is at least from the Windsor family and of course has strong links back to the original 289FIA cars. Because of registration regulations here in South Australia, it must comply with “Australian Design Rule 37/01”. This means that the engine has to wear all of its 2002 vintage emissions equipment which then allows a tick on the form at registration time; no emissions testing is required.

Further information: our local South Australian Cobra Club has been in discussions for some time with our State Government Transport Department regarding the possibility of relaxing these requirements for our Cobras. If successful, I would then be able to modify the engine to look much closer to an original FIA/USRRC car’s engine.

Short question, and long answer

Cheers!

Glen |

09-25-2020, 02:56 AM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

Heat shield for the master cylinders (left) and the mounting bracket / heat shield for the remotely mounted reservoirs (right), each part now insulated on both sides....

|

09-30-2020, 09:33 PM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

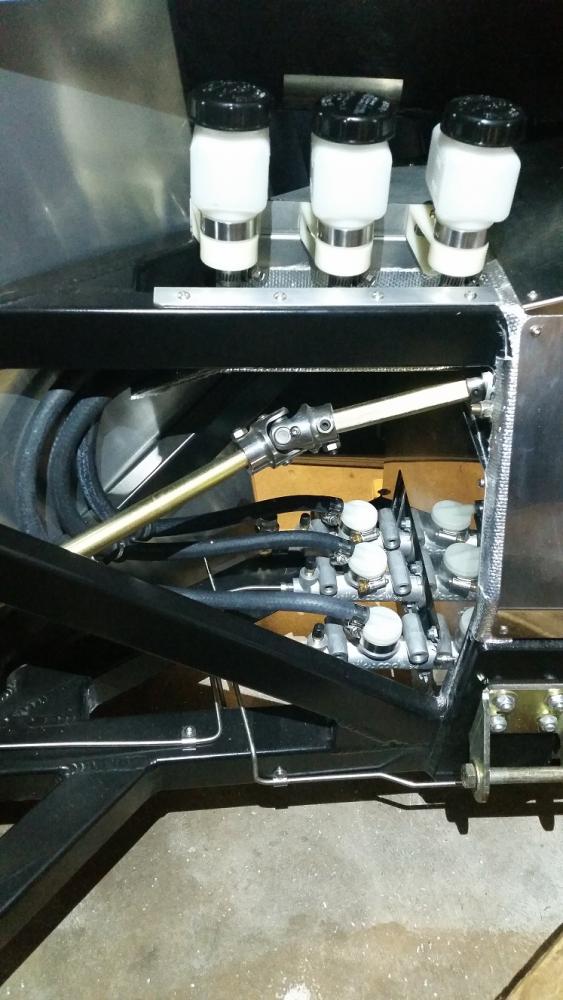

Brake reservoirs now mounted....

|

11-02-2020, 02:36 AM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

Greetings!

Slow (ie not much!) progress lately. Some other significant distractions to be attended to here.

On advice, did some minor rework on the master cylinder setup. Seems that the Wilwood setup needs to be spot-on to avoid leaks....changed the clamping to improve the chances of success....so soon about to start bleeding the brakes.

Here's what it looks like (not original, but my hands are tied to some extend  ) ...

Cheers!

Glen |

11-02-2020, 02:44 AM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

One job that didn't take too long to complete in the last couple of days is a tow lug for the front end.

It's 50mm x 6mm section mild steel, ø25mm hole, attached to the chassis with a couple of M12 bolts, so should be sufficient, yes?

Cheers,

Glen |

11-09-2020, 03:58 AM

|

|

CC Member

|

|

|

Join Date: Aug 2009

Location: Adelaide,

SA

Cobra Make, Engine: AP 289FIA 'English' spec.

Posts: 13,152

|

|

Not Ranked

Not Ranked

Finished the clutch plumbing hard line....

Cheers,

Glen

|

11-21-2020, 04:01 PM

|

|

CC Member

|

|

|

Join Date: Oct 2017

Location: Adelaide,

SA

Cobra Make, Engine: ICCARS,6.0LT L98 TR6060

Posts: 78

|

|

Not Ranked

Not Ranked

Looking good Glen, your plumbing is very tidy, it may be an idea to check with your engineer re brake pressure switch, i believe that with 2 separate master cylinders (front and rear systems independent of each other) you need a pressure or float switch on both master cylinders.

Richard

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 10:00 PM.

Links monetized by VigLink

|