05-17-2008, 09:24 AM

|

|

CC Member

|

|

|

Join Date: Nov 2006

Cobra Make, Engine: ERA, FE BBF

Posts: 389

|

|

Not Ranked

Not Ranked

ERA 753 - Final Assembly in Progress

ERA 753 - Final Assembly in Progress

Hi Everyone,

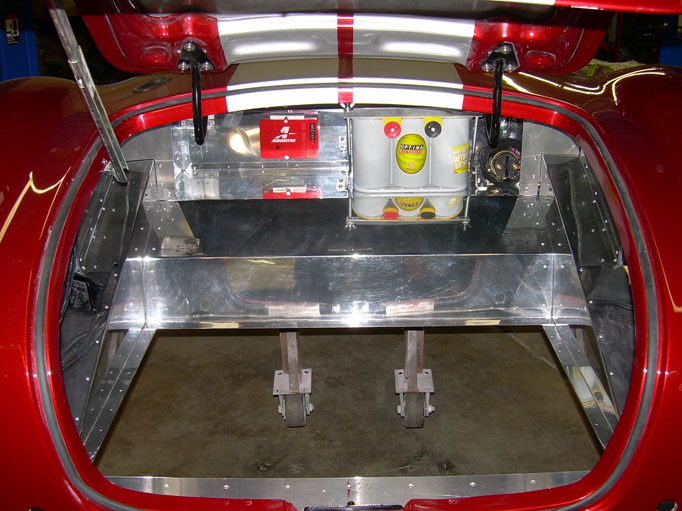

I thought I'd post a few pictures of ERA 753 as final assembly has begun. Attached is a picture of the nearly completed trunk area with polished aluminum panels and eletrical components installed.

The red box on the left is an electronic fuel pump controller (the car with have a Keith Craft 482 FE aluminum side-oiler with TWM Injection).

Progress on the front of the car is shown in the next picture.

Ron Randall at Metal Morphous smoothed out, painted, and clear coated my footboxes to give them a really smooth appearance.

I've started a build page on our ERA. You can find more information on the car there.

427SC Shelby Cobra Roadster

Enjoy!

Last edited by fkemmerer; 06-17-2009 at 07:18 PM..

|