Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

February 2026

February 2026

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

|

CC Advertisers

CC Advertisers

|

|

10-17-2007, 09:42 AM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,383

|

|

Not Ranked

Not Ranked

Need help figuring out my CAM info.

Need help figuring out my CAM info.

I am hoping someone can help me figure out what this information is that I received with my Cam.

I would like to find out if this is a good cam or if I should think about tossing it and installing a new one. Also the second document below what could this be?

Intake

Lobe Separation = 111.9

Valve overlap= 23.4

Valve open 14.6

Center line= 115.8

Valve close= 50.2

Duration: 244.37

Lobe Lift= .65956

Lobe area 30.85

Exhaust

Valve open = 60.5

Centerline = 115.8

Valve Close = 8.9

Duration 249.3

Lobe lift .3789

lobe Area 31.83

Second document

Intake 245 @.050

Exhaust 250 @.050

.650 Lift

Compression 9.5

Intake Exhaust

.200 150.4 114.3

.300 206.5 151.5

.400 256.6 179.2

.500 292 195

.600 306 208

.700 312 320

|

10-17-2007, 10:21 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Guessing a bit...

Guessing a bit...

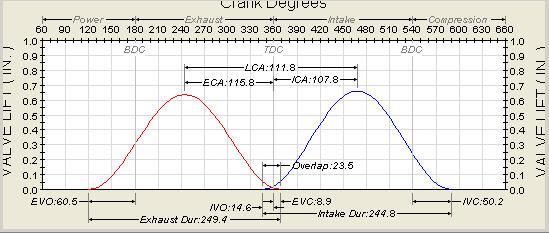

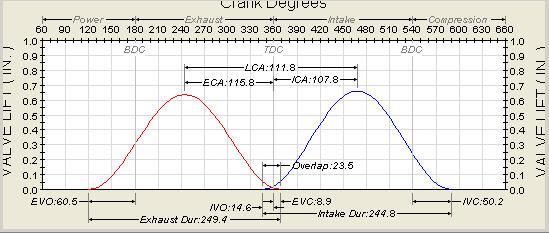

Not knowing the engine, not knowing whether you're using hydraulic, solid, roller, or what, and not knowing what the intended purpose of the cam is, and having to guess at what the true exhaust lobe lift number is (.3789 can't be right) I can definitively say it's perfect (for someone at least, maybe not you).  Seriously, here's a rough graph of the lobes. Can you fill in the blanks on what it is you're going to be using it for and with?

|

10-17-2007, 11:51 AM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,383

|

|

Not Ranked

Not Ranked

Sorry here is the info.

Used in: Cobra

Engine: 427 SO

Heads: Aluminum

Purpose: speed have fun

Induction: Webers

Cam: solid roller

Correction to specs

Intake

lobe lift - .37689

Valve lift - .65956

Lobe area 30.85

Exhaust

lobe lift - .3789 (this is what is indicated on the card - maybe it should be .63789)

Valve lift - .66307

lobe area - 31.83

|

10-17-2007, 12:13 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

A duration at .05 of 245 or 250 with a lift of .650 is slightly warmer than mild, the idle should be reasonably pleasant. As I recall, the original sideoiler cam had a similar duration, albeit with less lift and more overlap. When it comes to cams though, I tend to go with one that has been used sucessfully in a similiarly built engine -- was this specific cam recommended to you? You should be aware that there was an ongoing debate on whether solid rollers have an adequate life span in an FE. At one time, the recommendation was that a solid roller cam in an FE needed to be pulled out and replaced periodically. That may have changed though in the last few years. Perhaps one of the more savvy FE builders can give an update on that.

|

10-17-2007, 01:22 PM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,383

|

|

Not Ranked

Not Ranked

This cam was recommended by a company called Cam Motion. When I called them to find out if another spec cam would be worth the change. They told me that this cam is perfect and I would not gain any more benifit from another cam

|

10-17-2007, 01:34 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by priobe

This cam was recommended by a company called Cam Motion. When I called them to find out if another spec cam would be worth the change. They told me that this cam is perfect and I would not gain any more benifit from another cam

|

So that cam is already in your engine, and presumably running fine, and you're just thinking about maybe replacing it with something else? |

10-17-2007, 08:44 PM

|

|

CC Member

|

|

|

Join Date: Apr 2007

Cobra Make, Engine: # 757 ERA 427 SC , 482 Al. big block

Posts: 898

|

|

Not Ranked

Not Ranked

427 Cam

427 Cam

Patrick is pretty much on the money with his comments about the sideoiler cam as I currently have a 63 1/2 Galaxie 427 that I play with .... at least until my ERA comes in ( Chassis # 757 ..... I hope ) . From what I can find out , Ford offered three cams .... one that came in the car ( except that mine had a Holman and Moody grind in it ) , a street/strip cam and a strip cam only . The biggest lift I have seen published is .500" on Intake and Exhaust. In my info , they give duration as advertised instead of at 50 thou .

Patrick , your graph really intrigues me as I have not seen a cam`s specs plotted out like this before ... but it really illustrates the area under the lobes .... which is energy . The more area , generally , the better the cam performs . The cam grinders I know tell me the ideal cam opens and closes instantaneously and has a large area under the curve . Obviously , that can`t be done , but that is what they want to do .

I`m going with a hydraulic roller cam instead of the solid roller because of what you said .... life on the street . Solid rollers can have 300# + spring pressure open , which affects life . I have also had several cam grinders tell me that I would have to replace the solid rollers periodically . Therefore , the hydraulic roller cam . One thing I didn`t see in the cam specs is the closed and open spring pressures .

|

10-18-2007, 06:18 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: E BRUNSWICK N.J. USA,

Posts: 3,841

|

|

Not Ranked

Not Ranked

More info on the motor?

More info on the motor?

Proibe Could you give more info on the motor? Compression,heads and work done to them, Bore and stroke. What side pipes are you running? with or without mufflers? This is a large cam for a 427SO. Put this in a 484 motor and with the added cubes, it's streetable. Not sure how well the webers will run with this cam. If you are keeping the RPM under 6,500 rpm, go with a hydro roller lifter. You will need to change the Distributor gear also depending on the gear on the cam. I have a 484 with the small hydro roller from crane. Idle is a little loping and strong flat torque range for 2,500-6,200 rpm. Will have the numbers next week after the FI system gets the final dial in. Real numbers guess, at the crank 580ft tork and 490 hp. Figure there is about 10-20 hp sitting on the table before the final tuneup is done. There is a weber book that you might want to buy at Summit before you do the cam thing. I would find out who is running weber's and what cam they have. I do know that the 48mm webers runout of air at 6,800 rpm. With the right cam, midrange you pickup from 15-30hp over a carb, and they look great. You will need to buy extra jets,tubes, and possible chokes for them. You might want to look into a FI system like TWM. Look like webers but with FI run better when setup right. I have a set going on my 496 motor of 58mm TWM's. I am not a weber pro but there is something about cam overlap or dual patterns that they don't respond well to. Try the FE forum for more info. Rick L.

|

10-18-2007, 07:20 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by Bobcat

... but it really illustrates the area under the lobes .... which is energy . The more area , generally , the better the cam performs.

|

Of course you can micro-tweak the "area under the curves" with solids by either increasing or decreasing the lash. On the other hand, if I thought more people were reading this thread, I would make the broad-brush statement that Valve Lash on a Solid Lifter Cam Doesn't Matter (within reason) and see if anyone took issue with that statement. |

10-18-2007, 07:42 AM

|

|

CC Member

|

|

|

Join Date: Apr 2007

Cobra Make, Engine: # 757 ERA 427 SC , 482 Al. big block

Posts: 898

|

|

Not Ranked

Not Ranked

427 cam

427 cam

Patrickt .... wasn`t trying to criticize your analysis and I hope it wasn`t taken that way . To me , your graph was interesting as I haven`t seen a cam plotted out that way before . With most cams , you only get a "spec" card. As you pointed out , valve lash has a very limited effect on the cam`s performance . but does have some effect as we used to change lash and/or advance/retard at the track as a crutch when the track conditions changed . I would suspect that the acceleration and deceleration ramps ( rate of opening and closing ) have a much more pronounced effect on the area under the curve ... and that is the cam grinder`s area .

By the way ... nice car . Looks like you have done a first class job on it !

|

10-18-2007, 06:21 AM

|

|

CC Member

|

|

|

Join Date: Feb 2004

Cobra Make, Engine: FFR 390 toploader IRS

Posts: 258

|

|

Not Ranked

Not Ranked

What are you running for upper valve train??

Like said above, even the old 427 cams weren't over .500 lift.

Stock shafts don't seem hold up. Atleast be sure to use end supports.

Broke mine with a Crane .533/.563 lift.

Have since went with Ersons from DSC.

http://www.dscmotorsport.com/asp/Pro...asp?PartID=516

__________________

FFR MarkIII,FE,toploader,IRS,3.27,Vintage pin's SOLD!

68 F100 Custom Cab 418 cube FE/auto

99 SuperDuty Tuner/chipped/4" Banks TOTALED!!

02 Super Duty 7.3L

|

10-18-2007, 05:21 PM

|

|

CC Member

|

|

|

Join Date: Apr 1999

Location: cleveland,

OH

Cobra Make, Engine: CSX4000, 427

Posts: 1,999

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by priobe

I would like to find out if this is a good cam or if I should think about tossing it and installing a new one.

Intake

Lobe Separation = 111.9

Valve overlap= 23.4

Valve open 14.6

Center line= 115.8

Valve close= 50.2

Duration: 244.37

Lobe Lift= .65956

Lobe area 30.85

Exhaust

Valve open = 60.5

Centerline = 115.8

Valve Close = 8.9

Duration 249.3

Lobe lift .3789

lobe Area 31.83

Second document

Intake 245 @.050

Exhaust 250 @.050

.650 Lift

Compression 9.5

|

You need to talk to a weber guru, as that induction system seems to benefit / depend upon specific cam specs.

__________________

"After jumping into an early lead, Miles pitted for no reason. He let the entire field go by before re-entering the race. The crowd was jumping up and down as he stunned the Chevrolet drivers by easily passing the entire field to finish second behind MacDonald's other team Cobra. The Corvette people were completely demoralized."

|

10-18-2007, 07:40 PM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,383

|

|

Not Ranked

Not Ranked

Patrickt,

Here are the specs you asked for

Heads Edlebrock ported and polished matched to intake

Head Air Flow

2.190" Intake

.200 150.4

.300 206.5

.400 256.6

.500 292

.600 306

.700 312

1.730 Exhaust

.200 114.3

.300 151.5

.400 179.2

.500 195

.600 208

.600 208

.700 220

Now I dont know what these numbers mean so hopefully some could shed some light. I know they are air flow numbers but thats all.

Compression is 9.5:1

Bore and stroke is stock std bore & std crank 427

Side pipes are lobak from EM

Last edited by priobe; 10-18-2007 at 07:43 PM..

|

10-19-2007, 05:39 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by priobe

Compression is 9.5:1

Bore and stroke is stock std bore & std crank 427

Side pipes are lobak from EM

|

A standard bore and crank and your CR is 9.5 to 1? Well, I think what I would do to increase power on an otherwise nicely running 427 is start with the most minimally invasive procedures and work back from there before even thinking about taking parts of the engine out (I think your cam is probably fine). First, have your engine tuned properly on a chassis dyno -- this alone can pick up a significant amount of TQ & HP. Second, examine your sidepipes. I don't have personal experience with Lobak pipes but, if they're reasonably quiet, then they're robbing you of performance. After you've looked at those two things then my next step would be head work (but that starts to get slighly invasive). I tend to think the first two will probably suffice. On the off-chance that your "standard bore and crank" means that 427 has never had its short block touched, then you have a wonderful opportunity in front of you. |

10-19-2007, 07:35 AM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,383

|

|

Not Ranked

Not Ranked

Patrickt,

The bottom end has never been touch. It has only received polishing and checking of the crank. As for the Lobak mufflers, these are not quiet. This was the option that EM offered as their off-road race mufflers.

One of the major problems that I am having here in miami is that most of the chassis Dyno are owned by kids with no expierence with Webers. As for the heads they have been worked on already. Larger valves and ported and polished have been addressed. This has also extend into the intake.

It seems that their is nobody in miami that is experienced with the webers only book knownledge. Also I know there are many experienced people on this site with Webers but I am sure trying to describe the performance issues and troubleshooting the problem over the web is even harder.

I have spent alot of money & time with these webers ( which I am sure most weber owners have) but I am still not seeing the benifits of the webers.

My motor is running pretty good right now but maybe I am asking for too much. I have heard that webers run rich by nature. But when you read the books they tell you to do a plug cut and that the plugs should be light tan. I have only heard of only 1 individual that has been able to get the proper plug burn which is ElJaro.

I am sorry that this is turning into a weber topic but I wanted to find out if this cam was fine for me to proceed with the weber tuning.

|

10-19-2007, 08:03 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by priobe

One of the major problems that I am having here in miami is that most of the chassis Dyno are owned by kids with no expierence with Webers. As for the heads they have been worked on already. Larger valves and ported and polished have been addressed. This has also extend into the intake.

...

I have spent alot of money & time with these webers ( which I am sure most weber owners have) but I am still not seeing the benifits of the webers.

|

Virgin shortblock, ported, polished, matched, free flowing pipes ... sounds very, very nice. Again, I don't think the cam is your problem. To give you a rough benchmark, I run a stroked and bored 428 so the cubes are 447. I have a solid, flat tappet cam (245/525) that I would describe as mild. I do not have Webers; I have an old-style Holley 3310 (4160, with one metering block) -- a child could set it up. I put out 450HP using both mufflers and a water pump. Torque is just under 500 ft. lbs. I can't imagine your engine, with the Webers all in synch, not matching these numbers or beating them. Webers are absolutely gorgeous to look at -- no doubt about it. But they can be a nightmare to get, and keep, in synch. I don't know who the Weber experts are here on CC, but if that were my engine I would be inclined to fly them down for the day and pay them to teach me what I needed to know to get them set up right and to keep them that way. In view of what you've already got in that engine, that's a relatively cheap expense. |

10-19-2007, 08:19 AM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,383

|

|

Not Ranked

Not Ranked

Thanks for your info.

You are absolutely correct about flying someone down. I do however, have one more idea. I spoke to a gentlemen by the name of John at aircooled. He has many articles posted on the internet about rebuilding weber carbs. In our discussion he has asked me to fit a throttle position sensor to use with a the LM-1 analzer. With this information he told me he is able to tune the motor with the data logs. The only expense he is asking is that I purchase the jets from him (which is not a problem).

|

10-19-2007, 08:27 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by priobe

Thanks for your info.

You are absolutely correct about flying someone down. I do however, have one more idea. I spoke to a gentlemen by the name of John at aircooled. He has many articles posted on the internet about rebuilding weber carbs. In our discussion he has asked me to fit a throttle position sensor to use with a the LM-1 analzer. With this information he told me he is able to tune the motor with the data logs. The only expense he is asking is that I purchase the jets from him (which is not a problem).

|

Aircooled, they're in Utah, right? Ok... I'm skeptical, but OK. You might want to make sure that you have the bung positioned for the LM1 exhaust sensor just where he wants it and, presumably, on both sides of the engine. |

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 07:10 PM.

|

Seriously, here's a rough graph of the lobes. Can you fill in the blanks on what it is you're going to be using it for and with?

Seriously, here's a rough graph of the lobes. Can you fill in the blanks on what it is you're going to be using it for and with?

Hybrid Mode

Hybrid Mode