Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

|

CC Advertisers

CC Advertisers

|

|

16Likes 16Likes

03-01-2018, 08:34 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Alright, here are my tips for you, or anyone else that's reading this, to do this "fix" both with the carb on the engine, and with it off. Now remember, the goal here is to have your primary throttle blades set properly with regard to the transition slot, and your primary fuel/air mixture screws set properly so that your idle quality is nice at all under hood temperatures and so that your "light throttle" cruising has no lean surging. The idle RPM level will be set by the new secondary screw that you will be installing. The problem that you are trying to correct is that the density of the air that is going through the carb is WAY different when it is really, really hot as opposed to when in it nice and cool. Unfortunately, your carb only gets one single setting. Computer controlled fuel injection it ain't.

First, buy four 10-32 cap screws, a 3/4", a 1", a 1 1/4", and a 1 1/2". Then figure out which one of those four screws will be the most convenient to access with an Allen wrench once it is mounted to the same depth as the existing screw. Depending on your manifold and Turkey Pan combination, you might find that drilling an access hole in the Turkey Pan, that allows either a longer screw to poke through, or for the Allen wrench to come up through. Choose the screw that makes it easiest for you to get to, as you will be making slight idle adjustments once or twice a year, based mostly on the seasons. Inserting this screw can be done with the carb on the engine or off, but it is obviously easier to do with the carb off the engine. Insert your new screw with the same number of threads protruding up that the old screw had.

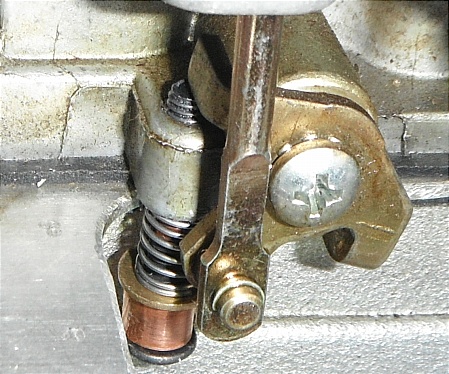

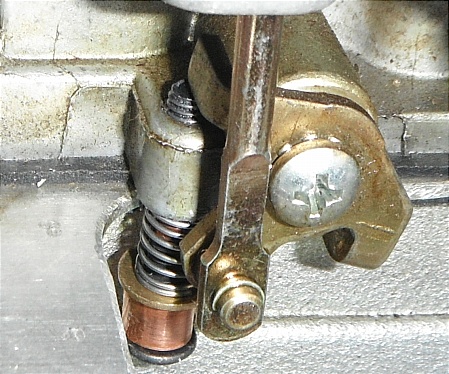

If you want to "get fancy," buy a 6 lb. spring, like you see in my pic above, and a washer for the screw. When you insert the new screw, just have the washer and spring "hanging loose" on it. Once the screw is adjusted properly, you can add that copper sleeve, that is just a piece of 3/8" copper tubing. It is cut to just the right length to apply good spring pressure. You get it around the cap screw by using your Dremel to cut a slot in the tubing so that it just barely slips on, and around the screw shaft, and then you use a pair of pliers to lightly squeeze the tubing tighter so it never falls off. That's how you get a perfect, custom fit. I also like to use a couple of drops of VC-3 "adjustable thread locker" on the threads. It doesn't harden, and allows you to make adjustments on the screw. https://www.vibra-tite.com/products/...-3-threadmate/

If the carb is off the car, flip it over and adjust the primary butterflies so that there is a "square" or less of the transition slot exposed. If the carb is on the engine, and you don't want to pull it off, then back the idle screw off on the driver's side until you see a "visible opening" between the screw and the idle lever. Then, place a pencil, eraser side down, in to the primary side of your carb so the eraser is sitting on the butterfly valve. Put a sticky tab on the point end of the pencil. Then slowly tighten up the idle screw until you see the pencil and sticky tab start to move (meaning you are now opening the primaries). Give it another 1/4 or half turn, but no more. Now lightly seat both idle mixture screws and back them out 3/4 of a turn.

Start the car and adjust the idle level by turning your newly installed secondary screw. Once you have a decent idle, take the car for a nice gentle drive where you see how she cruises at, say, 40 MPH, with your foot just ever so slightly giving gas. You should experience "surging" because of the lean mixture. Back each idle mixture screw out 1/8 of a turn and do it again until you have a nice clean, even engine performance with no surging when she is cruising with your foot just lightly on the throttle.

If your idle is too high, back your new secondary screw out a bit, if it's too low, screw it in a bit. You may also turn your regular idle screw in a bit. BUT NOT MUCH -- remember, we don't want to go in to the transition slot. Less is more in that regard. If you have "ham hands" you can visually see how much you're adjusting the new secondary screw by placing a clothes pin with a stick attached to it on the driver's side secondary throttle shaft. As you tighten the secondary screw in, while standing on the passenger side of the car, you will see the stick move clockwise. When you loosen it, it will move counterclockwise. It doesn't take much of a turn to that new screw to make significant changes to your idle. For a big FE, with a Holley 4160 on it, and an engine compartment that gets pretty darn hot, this is absolutely the best way to get your carb set perfectly. |

03-01-2018, 05:45 PM

|

|

Club Cobra Member

|

|

|

Join Date: Feb 2003

Location: Houston,

TX

Cobra Make, Engine: Kirkham/Southern 427 SO finally on the road

Posts: 508

|

|

Not Ranked

Not Ranked

WOW! Patrick, thanx for the schooling. much appreicated. i'll have to take the car back off the car to get the second, errant, gasket in,so i'll R&R the screw then. s

__________________

steve meltzer

"I may be wrong, but I'm never in doubt"

|

03-01-2018, 05:49 PM

|

|

Club Cobra Member

|

|

|

Join Date: Feb 2003

Location: Houston,

TX

Cobra Make, Engine: Kirkham/Southern 427 SO finally on the road

Posts: 508

|

|

Not Ranked

Not Ranked

oops. i didn't see the picture you referenced in your long and detailed instructions. thanx. s

__________________

steve meltzer

"I may be wrong, but I'm never in doubt"

|

03-01-2018, 06:40 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

I can not emphasize enough the role of the transition slot, and the positioning of the throttle blades along that slot, in getting your engine to run right. You have a big FE, a healthy cam that lowers your vacuum, along with hot under hood temps. If you have your throttle blade up deep in to the transition slot, then you're negating the effect of the idle mixture screw and actually defeating the whole purpose of the transition slot to begin with. The transition slot is really a beautiful little engineering design. When your throttle blade is down at or below the bottom of the slot then the slot is actually feeding fresh air in to the emulsified fuel. But as you open the throttle, and the blade moves up the slot, the portion of the slot that is below the blade grows larger and brings in more pure emulsified fuel instead of air -- it "transitions." It's a beautiful, simple design.

|

03-02-2018, 06:33 PM

|

|

Club Cobra Member

|

|

|

Join Date: Feb 2003

Location: Houston,

TX

Cobra Make, Engine: Kirkham/Southern 427 SO finally on the road

Posts: 508

|

|

Not Ranked

Not Ranked

Patrick, thanx again. let me digest this and get some wrench time in, hopefully, this weekend. my life and job are interfering with my fun. s

__________________

steve meltzer

"I may be wrong, but I'm never in doubt"

|

03-02-2018, 07:14 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by steve meltzer

Patrick, thanx again. let me digest this and get some wrench time in, hopefully, this weekend. my life and job are interfering with my fun. s

|

Alright, get cracking... and remember the Club Cobra Credo: "See One, Do One, Brag About One." |

03-02-2018, 08:08 PM

|

|

Club Cobra Member

|

|

|

Join Date: Feb 2003

Location: Houston,

TX

Cobra Make, Engine: Kirkham/Southern 427 SO finally on the road

Posts: 508

|

|

Not Ranked

Not Ranked

Hmmm....vaguely like my residency training...see one, do one, teach one...

and our credo: we teach the unteachable, train the untrainable and accept the unacceptable.

s

(now sporting a tee-shirt with a frog that says "don't croak on my shift")

__________________

steve meltzer

"I may be wrong, but I'm never in doubt"

|

10-04-2018, 07:49 AM

|

|

CC Member

|

|

|

Join Date: Dec 2006

Location: Southbury,

ct

Cobra Make, Engine: ERA, 428, 4 speed Toploader, Jag rear, Red with White stripes

Posts: 945

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

Alright, here are my tips for you, or anyone else that's reading this, to do this "fix" both with the carb on the engine, and with it off. Now remember, the goal here is to have your primary throttle blades set properly with regard to the transition slot, and your primary fuel/air mixture screws set properly so that your idle quality is nice at all under hood temperatures and so that your "light throttle" cruising has no lean surging. The idle RPM level will be set by the new secondary screw that you will be installing. The problem that you are trying to correct is that the density of the air that is going through the carb is WAY different when it is really, really hot as opposed to when in it nice and cool. Unfortunately, your carb only gets one single setting. Computer controlled fuel injection it ain't.

First, buy four 10-32 cap screws, a 3/4", a 1", a 1 1/4", and a 1 1/2". Then figure out which one of those four screws will be the most convenient to access with an Allen wrench once it is mounted to the same depth as the existing screw. Depending on your manifold and Turkey Pan combination, you might find that drilling an access hole in the Turkey Pan, that allows either a longer screw to poke through, or for the Allen wrench to come up through. Choose the screw that makes it easiest for you to get to, as you will be making slight idle adjustments once or twice a year, based mostly on the seasons. Inserting this screw can be done with the carb on the engine or off, but it is obviously easier to do with the carb off the engine. Insert your new screw with the same number of threads protruding up that the old screw had.

If you want to "get fancy," buy a 6 lb. spring, like you see in my pic above, and a washer for the screw. When you insert the new screw, just have the washer and spring "hanging loose" on it. Once the screw is adjusted properly, you can add that copper sleeve, that is just a piece of 3/8" copper tubing. It is cut to just the right length to apply good spring pressure. You get it around the cap screw by using your Dremel to cut a slot in the tubing so that it just barely slips on, and around the screw shaft, and then you use a pair of pliers to lightly squeeze the tubing tighter so it never falls off. That's how you get a perfect, custom fit. I also like to use a couple of drops of VC-3 "adjustable thread locker" on the threads. It doesn't harden, and allows you to make adjustments on the screw. https://www.vibra-tite.com/products/...-3-threadmate/

If the carb is off the car, flip it over and adjust the primary butterflies so that there is a "square" or less of the transition slot exposed. If the carb is on the engine, and you don't want to pull it off, then back the idle screw off on the driver's side until you see a "visible opening" between the screw and the idle lever. Then, place a pencil, eraser side down, in to the primary side of your carb so the eraser is sitting on the butterfly valve. Put a sticky tab on the point end of the pencil. Then slowly tighten up the idle screw until you see the pencil and sticky tab start to move (meaning you are now opening the primaries). Give it another 1/4 or half turn, but no more. Now lightly seat both idle mixture screws and back them out 3/4 of a turn.

Start the car and adjust the idle level by turning your newly installed secondary screw. Once you have a decent idle, take the car for a nice gentle drive where you see how she cruises at, say, 40 MPH, with your foot just ever so slightly giving gas. You should experience "surging" because of the lean mixture. Back each idle mixture screw out 1/8 of a turn and do it again until you have a nice clean, even engine performance with no surging when she is cruising with your foot just lightly on the throttle.

If your idle is too high, back your new secondary screw out a bit, if it's too low, screw it in a bit. You may also turn your regular idle screw in a bit. BUT NOT MUCH -- remember, we don't want to go in to the transition slot. Less is more in that regard. If you have "ham hands" you can visually see how much you're adjusting the new secondary screw by placing a clothes pin with a stick attached to it on the driver's side secondary throttle shaft. As you tighten the secondary screw in, while standing on the passenger side of the car, you will see the stick move clockwise. When you loosen it, it will move counterclockwise. It doesn't take much of a turn to that new screw to make significant changes to your idle. For a big FE, with a Holley 4160 on it, and an engine compartment that gets pretty darn hot, this is absolutely the best way to get your carb set perfectly. |

I do not see the pic you mention in your 3rd paragraph?

__________________

ERA#698 428, 4 speed Toploader, 3:31 Jag rear

|

10-04-2018, 08:02 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Vanishing Pics

Vanishing Pics

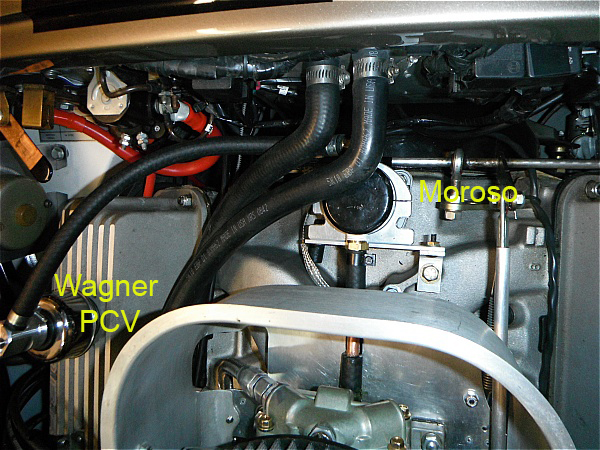

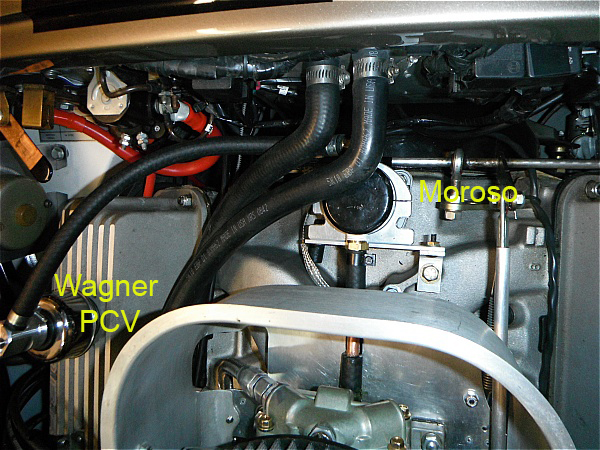

Here are two pics that seem to vanish from time to time.

|

10-04-2018, 05:50 PM

|

|

Club Cobra Member

|

|

|

Join Date: Feb 2003

Location: Houston,

TX

Cobra Make, Engine: Kirkham/Southern 427 SO finally on the road

Posts: 508

|

|

Not Ranked

Not Ranked

Patrick, an off idle question. 4160 on my '67 'Vette. Car starts great, runs great, idles great, but even a modestly brisk touch of the accelerator pedal and the car dies. So off idle response is zip. Correct squirter is a 26, I think. Moving to a 31 didn't help. can't recall the color of the cam, nor what is called for (it's a list 3180...and Holley tech couldn't tell me what cam was correct). I think the issue is the cam, but could this be a float issue or timing?

I need to confirm that the advance weights are moving, but the "pump shot" is good (even tried a new a/p diaphragm). Any thoughts? thanx. steve

(oh, yeah, my Cobra is still for sale).

__________________

steve meltzer

"I may be wrong, but I'm never in doubt"

|

10-04-2018, 06:14 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

It's not a float issue. Pull the distributor cap off and inspect the springs and weights, then put a timing light on your marks and watch the movement of the marks as you rev the engine up to 3000 or so. The curve, of course, is based on the spring choice but you should be able to see the marks move smoothly up to a total of 34 to 36. I don't think it's a timing issue though. How do you know your pump shot is working well? Have you put some towels under the squirter, so you're not just dumping fuel down the carb, and then, by hand with the engine off, give several pumps on the throttle linkage and see the gas squirt out with your own two eyes. Do that several times and see if you can get a "dry pump." All pumps should be nice and "streamy" until your float bowl is empty, which is a whole lot of gas. Now, remember, you're working on a cold engine. An imaginative solution would be an accelerator pump diaphragm that only fails to hold pressure when it gets hot. A little GoPro zip-tied to show what your squirts look like while actually driving would disclose that goofy scenario. My money is on a failure to squirt properly.

|

10-04-2018, 07:44 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Before I even thought about disassembling the carb, I would switch the one on the Cobra over to the Vette and take her for a quick ride. If the problem vanished, then I'd be pretty sure it was a carb problem.  |

10-05-2018, 03:45 AM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: Brisbane,

QLD

Cobra Make, Engine:

Posts: 2,797

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by steve meltzer

Patrick, an off idle question. 4160 on my '67 'Vette. Car starts great, runs great, idles great, but even a modestly brisk touch of the accelerator pedal and the car dies. So off idle response is zip. Correct squirter is a 26, I think. Moving to a 31 didn't help. can't recall the color of the cam, nor what is called for (it's a list 3180...and Holley tech couldn't tell me what cam was correct). I think the issue is the cam, but could this be a float issue or timing?

I need to confirm that the advance weights are moving, but the "pump shot" is good (even tried a new a/p diaphragm). Any thoughts? thanx. steve

(oh, yeah, my Cobra is still for sale).

|

Steve,

Perhaps your list number is a 3810 not 3180, since 3180 does not exist?

A list 3810 is a 585 cfm 4160, runs a 65 main, 25 pump, a purple sec spring, similar to the average list 1850 600 cfm with a 66 main, 25 pump, and plain sec spring.

Alas I can't tell you the cam yours should have, but most 600s come with a white cam.

Although this pic shows a red cam:

http://www.chicagocorvette.net/item....m=7232&rc=1437

And this one is also red:

https://www.ebay.com.au/itm/67-Corve...oAAMXQMTlRcPsX

So looks like Red could be correct, but run the smallest pump cam that gives throttle response with no flatspot. White is 17cc or 19.5cc, Red is 18.5cc or 20cc.

You could have some seizing advance weights.

Verify the float levels are correct, then a timing light on the balancer to check the advance is happening from say 1100 rpm up.

Gary

__________________

Gary

Gold Certified Holden Technician

Last edited by Gaz64; 10-05-2018 at 04:11 AM..

|

10-05-2018, 05:04 AM

|

|

CC Member

|

|

|

Join Date: Dec 2006

Location: Southbury,

ct

Cobra Make, Engine: ERA, 428, 4 speed Toploader, Jag rear, Red with White stripes

Posts: 945

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

Here are two pics that seem to vanish from time to time.

|

Very nice, thank you.

Sorry for the double post

__________________

ERA#698 428, 4 speed Toploader, 3:31 Jag rear

|

10-05-2018, 03:18 PM

|

|

Club Cobra Member

|

|

|

Join Date: Feb 2003

Location: Houston,

TX

Cobra Make, Engine: Kirkham/Southern 427 SO finally on the road

Posts: 508

|

|

Not Ranked

Not Ranked

thanx guys for all of the advice. will try to get to it tomorrow. thanx again. steve

__________________

steve meltzer

"I may be wrong, but I'm never in doubt"

|

10-05-2018, 03:19 PM

|

|

Club Cobra Member

|

|

|

Join Date: Feb 2003

Location: Houston,

TX

Cobra Make, Engine: Kirkham/Southern 427 SO finally on the road

Posts: 508

|

|

Not Ranked

Not Ranked

oh yeah...Gary, pardon my (recurrent) dyslexia, yes, 3810, not 3180

__________________

steve meltzer

"I may be wrong, but I'm never in doubt"

|

10-05-2018, 03:21 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by steve meltzer

thanx guys for all of the advice. will try to get to it tomorrow. thanx again. steve

|

No, you should do it today. We're not sure you're working hard enough; yep, we think you're just goofing off.  |

10-05-2018, 03:29 PM

|

|

Club Cobra Member

|

|

|

Join Date: Feb 2003

Location: Houston,

TX

Cobra Make, Engine: Kirkham/Southern 427 SO finally on the road

Posts: 508

|

|

Not Ranked

Not Ranked

ah jeez Patrick, i was hopin' to get lucky today. s

__________________

steve meltzer

"I may be wrong, but I'm never in doubt"

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 02:57 AM.

Links monetized by VigLink

|