Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

December 2025

December 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

1 |

2 |

3 |

4 |

5 |

6 |

| 7 |

8 |

9 |

10 |

11 |

12 |

13 |

| 14 |

15 |

16 |

17 |

18 |

19 |

20 |

| 21 |

22 |

23 |

24 |

25 |

26 |

27 |

| 28 |

29 |

30 |

31 |

|

|

|

|

CC Advertisers

CC Advertisers

|

|

06-28-2010, 12:11 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2007

Cobra Make, Engine: KMP 539, a Ton of Aluminum

Posts: 9,592

|

|

Not Ranked

Not Ranked

Oh Ernie, stop picking and choosing data and not showing the dyno tests of GM versus Ford.

Which heads are looking at? Are you picking the smallest ones? Exhaust side only? Where is the Ford tunnelport and HR data?

|

06-28-2010, 12:23 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2007

Cobra Make, Engine: KMP 539, a Ton of Aluminum

Posts: 9,592

|

|

Not Ranked

Not Ranked

Since you haven't supplied any data, here's one of top FE gurus, Jay Zolko, with flow numbers for his heavily-worked over HR heads.

http://www.network54.com/Forum/74182...e+flow+numbers |

06-28-2010, 12:27 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

With so many variables and choices for heads it is difficult to pick and choose. I'm speaking in general terms here, "counter point" to what I belive are basic myths concerning the FE series engines, posted in this thread.

Claims such as "no way a stock FE with period correct parts could make 600 horse." Pure BS, 600 horse is easy to make, with period correct parts. Using modern parts, on pump gas, with "nothing special" type of parts you can get 800 plus horse! Another "myth", High Riser heads quote/unquote, "didn't flow squat". What IS "squat" for cfm? 200 cfm? 250 cfm? I'm saying ANY head that can flow 300 cfm is "kick ass", compare whatever heads you want. It's pretty clear that LESS than 300 cfm will easily support 600 horse! High Riser heads with just a little work, will flow 300, tunnel ports with 2.25 inch valves, more.

Something not commonly known about the side oiler vs center oiler block, which share the same bore size. The side oiler bore is "notched" or "relieved" at the top to unshroud the intake valve and improve flow. The center oiler block is not. BOTH blocks will accept a High Riser head, but only the notched block will be able to take full advantage of the flow. So, when measuring High Riser flow, or any heads for that matter, is that flow calculation also considering the BLOCK bore modifications, if any. Or, is the flow simply measured at a given bore size with no mods?

As I mentioned earlier, High Rise heads will flow 290 cfm (500 lift, CONSIDERABLY more with higher lift). Shelby STAGE TWO heads will flow 293 cfm.

Last edited by Excaliber; 06-28-2010 at 12:30 PM..

|

06-28-2010, 03:49 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Excaliber

Something not commonly known about the side oiler vs center oiler block, which share the same bore size. The side oiler bore is "notched" or "relieved" at the top to unshroud the intake valve and improve flow. The center oiler block is not.

|

Ernie,

With all due respect, some things you say (whether by design or misinformation) are just not true, heresay, or junk science.

Here is my STANDARD BORE SO, torn-down for installation of my then new STAGE II Shelbys. This is NOT a notched block. My previous iron MR's were modified with 2.250's and 1.75's-same as the new Shelbys. My machinist did not notch the block as it was not necessary for clearance. The location of the valves in the chamber cleared the bore walls as does the Shelbys.

That's red Dykem I applied, installed the head without gasket and cycled the valves. The valves both I & E are not shrouded by the bore. The only blocks I've ever seen which required notches are the 4.13+ overbore 428's and smaller 390 blocks--which would carry 2.19 and bigger valves. Even Cammer heads do not require block notches. Further, I had several conversations with Mike LeFevers who R&D'd these heads and he assured me there was no need to notch the block-which is why I bought them-a straight bolt-on.

Quote:

Originally Posted by Excaliber

As I mentioned earlier, High Rise heads will flow 290 cfm (500 lift, CONSIDERABLY more with higher lift). Shelby STAGE TWO heads will flow 293 cfm.

|

JUST WRONG. Here is the Shelby spec sheet which came with my STAGE II heads. (Yes, I'm yelling). I apologize for the small scan-I don't know how to get it better. See right side data panel.

The STAGE I head intake flows 283 @ .600- THE STAGE II IS 320 AND 235@ .600.

I respect that you have built and rebuilt your own motor but I, like several others have expressed, do not believe that a 427 sized FE with Hi-rise heads, 13.5:1 and 2 660's made the famous 667 HP.

Given your above statement that (your?) Hi-risers flow(ed) 290@500-you would need a near .700 lift solid roller with 7000+ RPM capability and heads that flowed ABOVE 360 to achieve that 1.6HP/CI output. The pro builders on here with CNC programs for the EDE head are achieving 320-340cfm to mate with 482 inch combinations and juice rollers with lifts in the low to mid .600's. They regularly produce 600-630HP for their customers. It takes Blue Thunders at 360cfm+ to achieve the numbers you claim.

I also question Rod's reference source Jay Zolko believing he can achieve 800HP with Kuntz' head needing .950(!) to achieve 360cfm. Yes it didn't nose over but came from 315@.600. Kuntz is a wizard-I have seen his SBF custom head flow .408@ .800 at 28" on a SuperFlo without pipe.

Ernie- this thread had become a defensive p!ssing contest between you and the rest of the world. I'm just saying-if you continue to defend doubtful positions, please provide solid evidence to straighten us all out. And back your statements with facts-please.

__________________

Chas.

|

06-28-2010, 12:31 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

Bowl Port 64' HR FE

Intake - 2.190 Test temp - 80*F

.100 - 61.8

.200 - 128.9

.300 - 196.2

.400 - 253.0

.500 - 292.0

.600 - 316.4

.700 - 329.6

.800 - 336.0

.900 - 344.4

1.000 - 349.2

667 horse, 1964 High Riser heads, NOTCHED side oiler block, solid roller cam, NOT A PROBLEM!!!

Last edited by Excaliber; 06-28-2010 at 12:39 PM..

|

06-28-2010, 04:50 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

ERA Chas says, and I quote with all due respect (NONE),

Quote:

Ernie,

With all due respect, some things you say (whether by design or misinformation) are just not true, heresay, or junk science.

|

Your above post is filled with miss leading statements and BS.

First of all this isn't a pissing contest, it's a discussion, but with the attitude you bring to the table, yup, it's turning into a pissing match alright. So CALM DOWN, yes, I'm shouting.

There are exceptions to all the rules. Some center oiler 427's are notched, some side oilers aren't, most are. To bad your side oiler isn't, looks like you got some bad information and a non-standard side oiler, bummer. I reckon your heads will "flow enough" and a notch is not required for your expected horse power output. OK, thats fine with me and apparently Mike. Those intake valves of yours are certainly more shrouded than if you had the notched block. Oh well...

No question you gotta notch the smaller bore FE's to clear the big valves (390-428). Like I SAID, and now repeat, High Rise heads will fit a 427 bore, center or side oiler, which would infer, notched or not as the center oiler is NOT typically notched. There are many that believe FORD put the notch in there for a reason BEYOND valve clearance. Maybe some don't buy that, fair enough, but it sure has some logic to it.

Shelby Stage II heads will flow 293 cfm(293.8 at 500 lift to be exact). Your report shows 320 cfm, but fails to mention at what LIFT???? .900? a 1000? CFM don't mean squat without the details, just like dyno numbers don't mean squat without the details. Oh, and I certainly trust whatever Shelby has to say about his product (and pigs fly).

Where did I say how much MY High Rise heads flow? I didn't, so why are putting words in my mouth, or are you just trying to make this a pissing contest? My compression was only 12.5 to 1, not 13. Getting 700 or 800 horse out of a 427 is easy, getting it to LIVE and supplying a WARRANTY with that is the hard part! That's why a typical build is 600 horse (pick a number, any number you like) and not 800.

It's amazing to me that many of you guys actually think the Thunderbolts of 1964 were making a mere 425 horse. That's just crazy, most everyone from that era readily acknowledges an honest 500. The "debate" begins around 600 and more, as some claim they were making. Looking at the ET and Trap speeds of some of the top FE contenders into the mid to late 60's, those high horse power numbers are certainly valid with a 1/4 mile calculater. Using original parts!

You think TASCA Ford or Holman Moody or the NASCAR guys were just going to roll over and accept whatever Ford offered for an FE? 425 horse power? Gimme a break, man I gotta bridge for sale and a dozen pigeons right here ready to buy.

Last edited by Excaliber; 06-28-2010 at 05:11 PM..

|

06-28-2010, 05:26 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Your above post is a more eloquent statement about your lack of credibility than anything I have said. I could have rebutted every paragraph you wrote but the guys are smart enough to see the conjecture, made-up crap and tangents you flail around.

The last correction I will make is that the sheet I provided is not a 'report' but the spec sheet that came in the box with the heads. The lift is not shown-you got something right- but it's the flow figure at .600" as told to me by LeFevers. Call your machinist George Anderson who sells them to verify that. And look again at the StageII flow numbers-I've shown you the evidence from the manufacturer and you still claim the wrong data. That's why I posted in the first place-thanks for the supporting evidence. The sermonizing gets tiresome for the rest of us.

Instead of getting p!ssed you could have just said that you don't agree and we'd go on from there. I told you that I respected that you're a hands-on guy but that's the limit of 'benefit-of-doubt' I can muster. Some of your stuff is just too far-fetched with lame support.

Let's give the guys a break and just agree to disagree-you've been bounced from forums before and I won't contribute to any of that.

I'm done.

__________________

Chas.

|

06-28-2010, 05:26 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2007

Cobra Make, Engine: KMP 539, a Ton of Aluminum

Posts: 9,592

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Excaliber

Where did I say how much MY High Rise heads flow?

|

Ernie, you do quote somebody's flow data above and then follow it up with the statement of "667 horse, 1964 High Riser heads, NOTCHED side oiler block, solid roller cam, NOT A PROBLEM!!!"

That does lead one to think that while those aren't your heads in some flow test (though without any reference to who, where and what) that the numbers backup your HP claim of 667 HP. |

06-28-2010, 06:07 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

Well with so much data and number crunching around here it is easy to get confused for any of us. Which is why it's important to keep it a discussion, not a personal bashing opportunity. I don't know what MY high riser heads flow, I DO know they are worked over, but stop short of filling in the lower port area as might be done today for even more flow! Worked over in a manner like Tasca Ford, or Holman Moody or NASCAR would have done "back in the day". Without CNC machines and epoxy and 50 degree angle valve jobs and such. As such, I do believe the high riser iron heads of "yester year", with moderate work, are STILL to this DAY a valid comparison to modern heads with similiar work, call it "Stage II" perhaps.

Just like we often hear how the Cobra is "slow" compared to todays modern cars. But wait, WHAT modern cars are those we speak off? Inevitably we end up comparing a 40 year old car and it's old time tech to a HANDFUL of modern ultra high tech cars and the comparison is favorable, all things considered. Sure a modern Vett is faster, DUH, the fact we can even make that comparison speaks volumes about the Cobra!!!

Same for those old iron "back in the day" heads. Sure modern Blue Thunder's outperform, but the comparison is valid. Those "old heads" aren't bad, especially when you apply todays modern porting techiques! 1967, tunnel ports, STILL hard to beat, for instance. High Risers, with expoxy on the floor and raised ports, not bad at all. It would be a mistake to under estimate their potential, today or in 1965.

KC's basic FE offering today at 19K and change makes decent power, BUT, it surely leaves a bunch of potential power on the table. It's a low rpm hydro roller for one, low compression as well, put a solid roller in it, up the rpm, raise the C.R., there is a lot more power to be had. Do you need that more horse power? Not really, it has "enough" for good street manners, long life and excellent performance.

Last edited by Excaliber; 06-28-2010 at 06:14 PM..

|

06-28-2010, 06:18 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

It's a simple question ERA Chas, what do your Shelby heads flow at 500 lift? As I see it, and the numbers tend to vary to some degree, that would be 293.8 cfm. More of course at higher lift. So, I don't see a problem here,,, 320 at 600 lift? OK then, no problem.

When comparing flow data it should be noted at what lift, at a bare minimum.

|

06-28-2010, 06:38 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

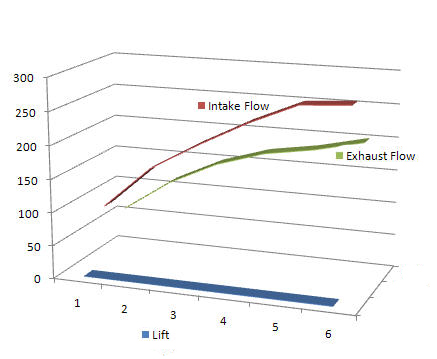

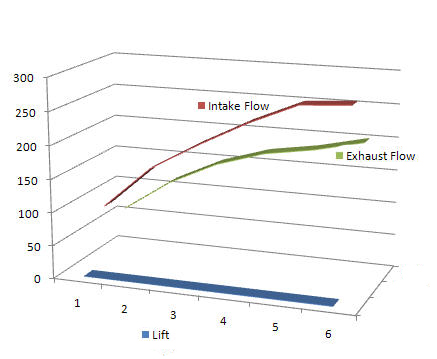

For Comparison Purposes Only

For Comparison Purposes Only

|

06-28-2010, 06:43 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

Some say the Shelby heads are lighter and thinner than the E-Brock heads and as a result the E-Brock heads can ultimately be made to flow more than the Shelby's. Maybe, maybe not, "rumor has it" anyway...

I recently saw some data points for Shelby Stage II heads flowing 314 cfm at 700 lift, by the way, must be flawed data, I guess, hard to keep track of it all.

One thing seems for sure though, you got some heads, any heads, that flow 300 cfm or better and your kicking butt and taking names!  |

06-29-2010, 10:17 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2007

Cobra Make, Engine: KMP 539, a Ton of Aluminum

Posts: 9,592

|

|

Not Ranked

Not Ranked

Ernie, you persuaded me. I'm now going to search for some High Rise(r) heads to replace my Edelbrocks. How much do they cost now? Like $3,500? Maybe $5,000 with the intake?

|

06-29-2010, 10:21 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

And with Edelbrocks, there doesn't seem to be too much of a gain over a lift of .500 or so unless you're going to have some significant head work performed on them.

Last edited by patrickt; 11-07-2016 at 01:57 PM..

Reason: added the cute little graph...

|

06-29-2010, 11:29 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Feb 2007

Cobra Make, Engine: KMP 539, a Ton of Aluminum

Posts: 9,592

|

|

Not Ranked

Not Ranked

My Edelbrocks were ported to a Stage 2 configuration. Is the info that you're providing for a "as cast" Edelbrock? CJ or MR?

If the BT heads didn't have raised exhaust ports, potentially requiring exhaust mods, there was a strong likelihood that I would have went that direction.

|

06-29-2010, 11:35 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by RodKnock

My Edelbrocks were ported to a Stage 2 configuration. Is the info that you're providing for a "as cast" Edelbrock? CJ or MR?

|

As cast. And apparently both flow the same, just different chamber volume. I think most of our builders "touch them up" a bit before putting them on though. But except for the big race cam, all of the old Ford cams stopped at .5 (when you subtract off the lash). Here's the page:

http://www.edelbrock.com/automotive_...perf_rpm.shtml |

06-29-2010, 11:35 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

I wouldn't bother with the old heads, any of the old heads, including Tunnel port, cool though they are.

Fact is, by the time you get the old heads cleaned up and ready to go it would cost as much as new alloy heads. Plus the alloy heads are much easier to repair in case of a problem, like loosing a guide or a valve seat. A common problem with the older heads. But if you have a set already, there not a bad choice, they got some soul, run 'em till their break and then move on.

Point is, I'm surprised how many folks on this thread discount the history of the FE and it's potential for power. If those GM big blocks were so good, if their heads flowed so much better, why didn't they set the records for that era? Fact is, the FE is one of the great race engines of it's time, GM couldn't touch it "back in the day."

While the many of those great old engines like the Buick Nail Head, the Olds, the Pontiacs (which were pretty awesome themselves) have faded into history, the FE found new life on it's way to that junkyard in the sky. New technology has brought it into the 21st century. It was and remains a worthy contender.

Consider the cfm flow of the heads as only one small factor in making horse power, there are a ton of other variables as well. But just looking at cfm flow we can estimate some basics. Like 300 cfm will support about 630 horse. Interesting that the Tunnel Ports did about 300 cfm and there is a documentation of all STOCK, period correct everything, no modifications at all, FE making a bit over 630 horse, with tunnel port heads. FT TRUCK engine heads can be modified to flow 300 cfm and there not even High Risers or Tunnel Ports! There is no question High Riser heads with some decent work will out flow stock Tunnel ports. Which means, they will easily support near 700 horse.

Theory has it 380 cfm will support about 780 horse. It's all just theory as it concerns flow and potential horse power. But there are enough examples to see that the theory often holds true. Assuming you match all the right components and eliminate the various bottle necks (no bad intake, cam, header, carbs, etc.). It's the combination of parts that speak louder than any single part.

BT heads, like an alloy block, are out of my price range. IF my side oiler detonates and cannot be repaired I would likely go with a modest 390 and shoot for about 500 horse, which is do-able. My neighbor just bought an old Ford pickup with a 390 (maybe it's a 391?), run's great! He paid $200 for it and drove it home. I might make him an offer, double his money. Potentially a steel crank!!  But my High Riser heads won't work on that engine...

Last edited by Excaliber; 06-29-2010 at 11:46 AM..

|

06-29-2010, 05:50 PM

|

|

Super Moderator

|

|

|

Join Date: May 2001

Location: Fresno,

CA

Cobra Make, Engine: KMP 184/482ci Shelby

Posts: 14,448

|

|

Not Ranked

Not Ranked

Gentlemen...

__________________

Jamo

|

06-29-2010, 06:00 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Bethesda,

MD

Cobra Make, Engine: CSX 6022, navy blue, period correct 427 SO

Posts: 2,154

|

|

Not Ranked

Not Ranked

There's a nice set of NOS MR heads that were just listed on CC if you want to experiment with flow on unmolested heads....

__________________

“There are only three sports: bullfighting, motor racing, and mountaineering; all the rest are merely games.”

www.partskeeper.com

(Less time searching, more time wrenching & driving)

|

06-29-2010, 06:15 PM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: San Jose CA,

CA

Cobra Make, Engine: SPF_R_/BRG/FRBoss302/327CI/FordEFI/Under_Car_Exh/

Posts: 2,523

|

|

Not Ranked

Not Ranked

I can vouch for the weight savings in ALUM blocks, and the difference in handling is worth it. --plus as an investment it would bring a benefit.

__________________

Steve SPF 2734 MK3 / Brock Coupe #54- panavia.com

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 12:20 AM.

|

|

Hybrid Mode

Hybrid Mode