Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

December 2025

December 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

1 |

2 |

3 |

4 |

5 |

6 |

| 7 |

8 |

9 |

10 |

11 |

12 |

13 |

| 14 |

15 |

16 |

17 |

18 |

19 |

20 |

| 21 |

22 |

23 |

24 |

25 |

26 |

27 |

| 28 |

29 |

30 |

31 |

|

|

|

|

CC Advertisers

CC Advertisers

|

|

2Likes 2Likes

06-30-2007, 07:06 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

place holder for fuel sender hook up

Last edited by David Kirkham; 07-03-2007 at 09:30 AM..

|

06-30-2007, 07:30 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

place holder for license plate light hook up

Last edited by David Kirkham; 07-03-2007 at 09:30 AM..

|

06-30-2007, 07:36 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

On the brake pedal box.

Here is a picture of the brake pedal box. In original Cobras the brake pedal box was not removable. Worse, the bottom of the pedal box was solid. The bottom didn't come off. It is VERY common for current owners of original cars to cut out the bottom of their pedal boxes so they can work on them. It is a most miserable chore to have to assemble a pedal box from inside the cockpit when the steering wheel is hitting you in the back and the gear shift lever is stuck in places I would rather not remember. Next time I have to install a pedal box in an original car I will hire someone from Cirque du Soleil to do it for me.

Anyway, here is what the bottom of our box looks like. It looks just like an original one, except we can unbolt ours and we rivet an aluminum access cover on the bottom of ours.

This is where we bolt the pedal box onto the car. There are two bolts in the rear (shown in the picture) and two bolts in the front. (not shown...at least yet).

Also, I had to take this picture from another one of our cars (Bobby Rahal's car  ) because my guys are bolting parts on faster than I can type!

Last edited by David Kirkham; 07-03-2007 at 09:44 AM..

|

06-30-2007, 07:43 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here are all the pieces you will need to complete your pedal box.

Here are your bolts.

Here are your parts. We call them the pedal box guts.

If you look closely at the brake and clutch pedal arms, you can see we drilled two holes in them. That way both pedals can be used for either the brake or the clutch arm. The upper hole (the one towards the part you push on with your foot) is used to hook to the clutch master cylinder. The lower hole is used to hook to the brake master cylinders balance bar assembly.

Last edited by David Kirkham; 07-03-2007 at 09:49 AM..

|

06-30-2007, 08:09 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

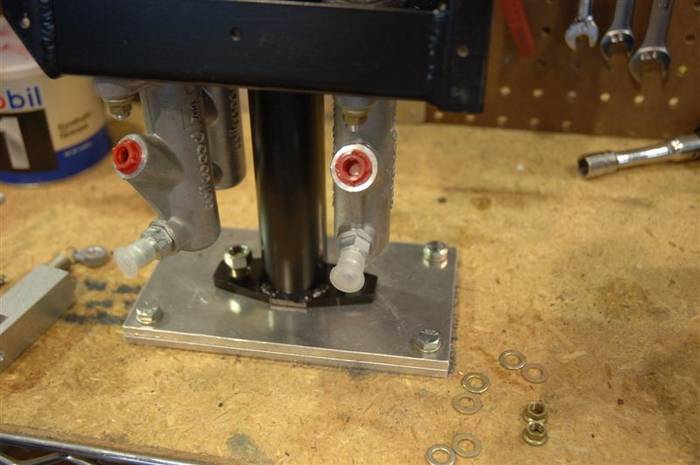

In this picture you can see 3 master cylinders. The one on the left (in the picture) is for the clutch. The one closest to you on the right (in the picture) is the FRONT brake master cylinder. The one furthest away from you on the right (in the picture) is the rear master cylinder. If you read the size on the master cylinder for the front brake master cylinder you can see it reads .700 or 11/16" bore.

Rear brake master cylinder is .750 or 3/4" bore.

The clutch master cylinder is .700 or 11/16"--just like the front brake master cylinder.

You can see in the below picture a little fitting that comes on all of the Wilwood master cylinders--straight out of the box. (I am pointing to it in the above picture). We throw them straight in the trash. You won't need them. Also, Joe got a little bit ahead of me assembling this pedal box and you can see the front brake master cylinder already has the brake reservoir fitting in it. On the master cylinder, the front opening (the one furthest away from the push rod) is a #4 o-ring boss fitting. The other side of the fitting is a #4 JIC which connects to the brake reservoir cans. There is no pressure on this fitting. It is simply where the brake fluid enters the master cylinder from the brake reservoir cans. If you get the billet reservoir can option on our list, then your brake fluid will not be rusty when it enters here.

Last edited by David Kirkham; 07-02-2007 at 01:39 PM..

|

06-30-2007, 08:12 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

After you get your master cylinders bolted in, you will want to put you "bell stops" on your brake master cylinders. The bell stops are a fail safe device. They are there in case of failure of one master cylinders. If one of the master cylinders fails, then it will no longer offer pressure against the balance bar and all of the brake pedal travel will then go to the failed master cylinder. This is a good way to meet your Maker very unexpectedly--or at least to ruin the leather in your seat. Under failed master cylinder conditions, the bell stop only lets the failed master cylinder push rod engage so far before it stops (hence the name) and forces the balance bar to act on the other cylinder. Don't forget them or someone on this forum (probably Jamo) will nominate you for the Darwin awards.

In between the master cylinders you can see the "brake guide." There is a long pin on the balance bar fork that goes into this bushing. The guide pin keeps the brakes aligned so they work properly. If you forget to put this piece in the brakes will jam and Jamo will be posting about you.

Last edited by David Kirkham; 07-03-2007 at 09:56 AM..

|

06-30-2007, 08:33 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Here the #4 o-ring boss to #4 JIC adapters are fitted into the master cylinders. You have to be VERY careful when you install them to not cut the o-rings or they WILL leak!

Last edited by David Kirkham; 07-02-2007 at 12:47 PM..

|

06-30-2007, 08:40 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

This is how you assemble the brake balance bar before it goes in. The actual balance bar is made out of 304 stainless and we cut it right here on our water jet.

Here is a picture of the other side of the balance bar--showing the brake return spring bracket that bolts into the middle of the balance bar.

Here Joe is putting in the bias bar. MAKE SURE THE SHAFT GOES INTO THE GUIDE BUSHING!!! It looks like in the photo that Joe is a little bit off, but he actually is not. You have to screw the clevis forks on the balance bar onto the push rods and it flops all over the place while you do it. If you don't want your pedal box guts to flop all over the place when everything is finally bolted together then MAKE SURE THE SHAFT ON THE BALANCE BAR FORK GOES INTO THE GUIDE BUSHING!!! It is worth repeating.

Last edited by David Kirkham; 07-03-2007 at 09:57 AM..

|

06-30-2007, 08:41 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Next, put the pedals in.

Notice in the below picture, Joe used shims on the brake pedal to get it all lined up properly. THIS IS CRITICAL!!! You have to work the brake pedals to make sure the guide pin slides freely and doesn't bind in the guide bushing. The bronze thrust washers need to be placed on both sides of the brake or clutch pedal. Any shims to straighten things out the go outside the bronze thrust washers.

Here is a picture of the shims. You can see the bronze thrust washers in the top of the photo. He selected the right thickness and shimmed everything perfect. When we send you the "Car in a box" we send you extra shims. You will not use all of them! Don't try! They will not all fit. We give you various thicknesses so you can line the balance bar fork shaft up perfectly.

Last edited by David Kirkham; 07-03-2007 at 09:59 AM..

|

| Thread Tools |

|

|

| Display Modes |

Hybrid Mode Hybrid Mode

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 03:59 AM.

|

|

2Likes

2Likes

) because my guys are bolting parts on faster than I can type!

) because my guys are bolting parts on faster than I can type!

Hybrid Mode

Hybrid Mode