Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

December 2025

December 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

1 |

2 |

3 |

4 |

5 |

6 |

| 7 |

8 |

9 |

10 |

11 |

12 |

13 |

| 14 |

15 |

16 |

17 |

18 |

19 |

20 |

| 21 |

22 |

23 |

24 |

25 |

26 |

27 |

| 28 |

29 |

30 |

31 |

|

|

|

|

CC Advertisers

CC Advertisers

|

|

2Likes 2Likes

07-03-2007, 05:48 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

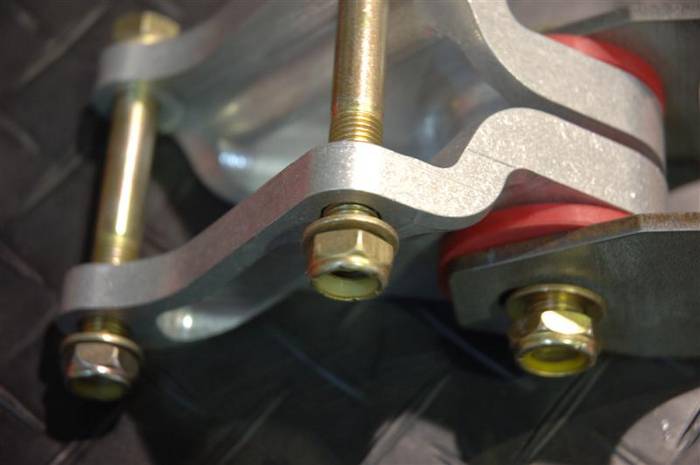

Notice we use aircraft 1/2 high nuts on the mount. We try to save weight everywhere we can.

Last edited by David Kirkham; 08-04-2007 at 01:07 PM..

|

07-03-2007, 08:14 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

And now, to the HEART of the matter.

Keith Craft Aluminum 427 FE

Shelby Aluminum Block

Scat 4.25 inch stroke crank

482 cubic inches

Aluminum Edelbrock Heads

Stage 2 CNC ported heads

Forged pistons

Edelbrock Performer RPM Heads

Aluminum Flywheel

600+ horsepower

This is how it arrives from Keith Craft

|

07-03-2007, 08:15 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

|

07-03-2007, 08:17 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

|

07-03-2007, 08:18 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

|

07-03-2007, 08:20 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

|

07-03-2007, 08:23 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Now it is time to give the motor the one over and make sure everything is OK. We always check the parallelism of the harmonic balancer pulley to the water pump pulley and we found this one was a little bit off. See the cool tool we use to make sure everything is in line? Peter Brock showed me that trick years ago. He told me they were loosing belts during races until someone figured out why.

|

07-03-2007, 09:53 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Well, as you can see, my guys are putting the car together faster than I can type and comment. I can see I am going to have to probably do this over 2 cars. We are building an identical one to this one right now. It is in sanding right now. Hey, that gives me an idea...maybe I should do this for sanding and polishing a car as well.

Here is the engine in the car.

|

07-19-2007, 06:52 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Finally a few minutes to get back to the assembly manual! Lots of sales this week. Mostly from overseas.

Everyone likes to put the Tremec 5 speed in today. It is WAY better than the top-loader 4 speed transmission. I really don't like to drive the 4 speed cars any more.

To use the Tremec transmission, you MUST change the input shaft to the shorter shaft. Many transmission shops can do this for you...but WHY? When you can have all the fun yourself and convince your wife you NEED to buy MORE TOOLS!!!

So, you have to do a few things to be able to use your brand new TKO 600 tranny. We will start with the input shaft. It is the hardest thing to do and I always start with the hard things first. Kinda like when I start a new Chopin piece on the piano...I alway start with the "Presto con Fuoco"  That way when I am tired I can do the easy stuff.

The first area to address is the input shaft. So, how do I change the input shaft on my Tremec TKO 600 transmission?

Just grab a cold one and I will give you the step by step procedure.

First, take off the input shaft snout. You will need a 1/2 socket for this.

Last edited by David Kirkham; 07-20-2007 at 06:00 PM..

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 12:15 PM.

|

|

2Likes

2Likes

That way when I am tired I can do the easy stuff.

That way when I am tired I can do the easy stuff.

Hybrid Mode

Hybrid Mode