Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

29 |

| 30 |

|

|

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

07-11-2009, 09:17 PM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: Sacramento,Ca.,

Ca.

Cobra Make, Engine: Midstates (2001)

Posts: 1,724

|

|

Not Ranked

Not Ranked

I wish i could have gotten mine sooner also BUT careful planning on my part made my build much easier than if i had no plan at all.I knew i wanted an FE for the look, I have bad knees so an auto was in order,I am not a big fan of chrome so it only got what was necessary to maintain the look,I wasnt building a racecar so it dosent have 600 hp,i chose the color very carefuly i wanted something that looked good on a very rounded car like a Cobra and thats the comment i get the most ,how the color appears to "move around the car" it almost looks like its alive, I love my Cobra and would only change the weather so i could enjoy it more.

|

07-16-2009, 11:47 AM

|

|

CC Member

|

|

|

Join Date: Jul 2009

Cobra Make, Engine:

Posts: 416

|

|

Not Ranked

Not Ranked

Only thing I would change (and still can) is to put a hole in the driver's footwell so I can access the lower left rear exhaust manifold bolt easier!!!

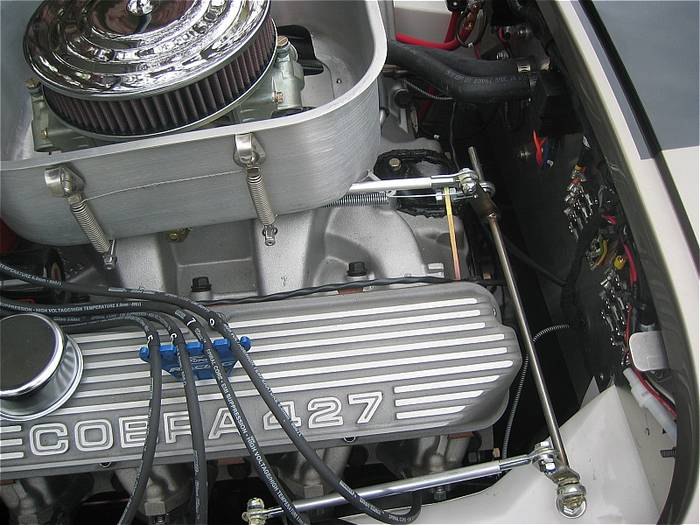

Oh wait!.....I stuck "COBRA 428" Branda valve covers on it. I am getting so sick and tired of people asking me why it says 428 on the engine, but 427 on the fender emblems. I really have to save some cash and get "COBRA LeMans" covers.

|

07-16-2009, 03:33 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Argess

Only thing I would change (and still can) is to put a hole in the driver's footwell so I can access the lower left rear exhaust manifold bolt easier!!!

Oh wait!.....I stuck "COBRA 428" Branda valve covers on it. I am getting so sick and tired of people asking me why it says 428 on the engine, but 427 on the fender emblems. I really have to save some cash and get "COBRA LeMans" covers.

|

You can get the exhaust bolt from below with a bent wrench. Make the footbox hole for the #8 spark plug. Make small cover from .005 aluminum or tin with tap screws to close that hole or heat will kill you.

__________________

Chas.

|

07-16-2009, 04:31 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by ERA Chas

You can get the exhaust bolt from below with a bent wrench. Make the footbox hole for the #8 spark plug. Make small cover from .005 aluminum or tin with tap screws to close that hole or heat will kill you.

|

ERA Chas - Does your footbox and #8 clearance look like this? I'm wondering if some of the changes ERA made starting with car #731 included trying to fix that problem.

|

07-16-2009, 04:50 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Yes the footbox has that general shape. The early cars (which is what I have) do not have the extended boxes which came later but I do not know at what chassis number.

The difference with my car is the reservoir which is mounted on top and the clutch line which crosses the footbox and goes down the side to the clutch master right at the last exhaust port. My clutch hard line is covered in Firesleeve for that reason.

You later number guys have the 3 cans on the fender well. Don't know if 392 which Argess has came with the cans or my set up. I made that access hole 21 years ago.

__________________

Chas.

|

07-16-2009, 05:13 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by ERA Chas

I made that access hole 21 years ago.

|

Interesting. Do you have any trouble getting to your front driveshaft universal joint? |

07-16-2009, 06:09 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

Interesting. Do you have any trouble getting to your front driveshaft universal joint?

|

No.

It's a poor photo but the joint is well clear of the crossmember from below.

__________________

Chas.

|

07-16-2009, 06:12 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by ERA Chas

No.

It's a poor photo but the joint is well clear of the crossmember from below.

|

That's a breeze to get to. With the ERA rear handbrake bracket all of that gets covered up. With the right adapter I think I can get to mine through the gear shift trim ring hole, otherwise I'm going to put an access panel in the passenger side of the tunnel. |

07-17-2009, 07:40 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

My Problem is Obvious...

My Problem is Obvious...

Quote:

Originally Posted by ERA Chas

No.

It's a poor photo but the joint is well clear of the crossmember from below.

|

This is a shot taken from the trim ring hole with the shifter removed. It shows what I'm up against coming from beneath. I think with a long grease gun adaptor and one of those swivel gizmos at the end I can grease the u-joint through the trim ring hole, otherwise I'll pull the passenger seat out and install a trap door on the tunnel. Chas -- you did install a drive shaft safety hoop after snapping that picture, right?

|

07-17-2009, 08:00 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Dec 2001

Location: Shasta Lake,

CA

Cobra Make, Engine:

Posts: 26,615

|

|

Not Ranked

Not Ranked

The only thing I would have did different on mine was make a trap door in the trunk floor so I could get to the fuel sending unit as I had to drop the tank on it to do so. All the rest was very easy to get to under my car. I could have my transmission out and one the bench in 20 minutes.

Ron

|

07-17-2009, 08:59 AM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

This is a shot taken from the trim ring hole with the shifter removed. It shows what I'm up against coming from beneath. I think with a long grease gun adaptor and one of those swivel gizmos at the end I can grease the u-joint through the trim ring hole, otherwise I'll pull the passenger seat out and install a trap door on the tunnel. Chas -- you did install a drive shaft safety hoop after snapping that picture, right?

|

Yes, thanks for asking. This was reassembly after a clutch change in April.

__________________

Chas.

|

07-16-2009, 04:55 PM

|

|

CC Member

|

|

|

Join Date: Mar 1999

Location: TACOMA,

WA

Cobra Make, Engine: Everett Morrision FE 427 so 2-4s

Posts: 2,025

|

|

Not Ranked

Not Ranked

As far as the exhaust bolts coming lose. My heads are the Cobra Jet style with both exhaust bolt patterns but the end holes aren't used giving me a total of 14 bolts per side. I used the Stage 8 bolts with the small diameter hex heads for access and locking levers. I asked when on phone and found that the 3/8" x 3/4" bolt set part number with an (A) added got you 1" long bolt set to take full advantage of more of the threads available in my aluminum heads. I did buy a jig for drilling bolt heads for safety wire and had to leave the center two bolts on both sides levers off and just safety wire them up. A real long pain in the ass to assemble. Some bolts ended up behind pipe and had to go in in a sequence and then draw them all in each a little ata time. Good news I've never had one come lose after the whole procedure. I also used the copper exhaust gaskets. I lost way more bolts, levers, and locking rings on my floor when working on my car than I ever lost on the road. Just don't know where they fell to but remember I had 4 extra to start with because I had to order two sets of bolts. Also the small heads let me use the box end of the wrenches which were a deffinent advantage when working by feel.

__________________

Mike H

Last edited by Michael C Henry; 07-16-2009 at 05:05 PM..

|

07-17-2009, 06:06 AM

|

|

CC Member

|

|

|

Join Date: Jun 2008

Location: Central,

NC

Cobra Make, Engine: ERA #775

Posts: 324

|

|

Not Ranked

Not Ranked

patrickt and ERA Chas, great pictures! Since I haven't received my car yet, the pictures really allow me to understand the specifics of the point you're trying to convey.

Ray

|

07-17-2009, 06:31 AM

|

|

CC Member

|

|

|

Join Date: Jul 2009

Cobra Make, Engine:

Posts: 416

|

|

Not Ranked

Not Ranked

Yes, my car looks like Patrickt's, but my rear plug faces forward, so it isn't too bad to get at. Actually, the opposite one is more difficult due to the battery being in the way.

I made the "bent" wrench frm ERAs instructions. Slow, but the hard part is starting the bolt. What I've found is to start all 4 bottom bolts, lift the headers up over the bolts, and slide them down in their slots. Then put in the top bolts, but it's that right rear top one that's fiddly to start (did I say bottom before, I meant "top").

I'm really glad I got the proper pin-drives and wheels for the car. I'd regret it if I didn't. Leather seats and seat slides were another option I am pleased with.

I had ERA add in an extra cahssis suport for a full width roll bar, but so far, I am not using any roll-bar. I think I'll leave it that way as I don't do any track stuff.

I woudln't mind owning the convertible top, but I'd never use it. I do have the tonneau cover in case it starts raining when I am far from home. I can put the cover on and go in a store or somewhere until the rain stops.

LIttle things....I must get a 5-speed pattern shift knob. I did find a source recently. Apparetnly it's a legal thing here. Also is toggle switch labels. I machined new toggle switch nuts with a wide tapered edge (had to order a special thread tap), but couldnt' find an engraver who could do small compound curves, so i settled for professionally applied vinyl letters. All done, but never installed yet.....LOL.

I kind of think a kit car will always be a work in progress to some extent.

|

07-18-2009, 10:05 AM

|

|

CC Member

|

|

|

Join Date: Oct 2004

Location: Odessa,

TX

Cobra Make, Engine: SOLD: ERA FIA #2114 with 331

Posts: 262

|

|

Not Ranked

Not Ranked

I would of used a traditional clutch instead of the hydraulic throwout bearing setup. Also, I would of used a carb that has a choke! If the car sits for more than a day I have to pull the air cleaner and dump some gas down the carb.

|

07-18-2009, 11:06 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by iwantacobra427

If the car sits for more than a day I have to pull the air cleaner and dump some gas down the carb.

|

That's strange. My car sits from Thanksgiving to Easter untouched, and even after that it starts up after three or four throttle pushes and a few seconds of cranking. |

07-18-2009, 11:45 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jun 2007

Location: Covington,

wa

Cobra Make, Engine: Superformance # 532, 466 BB, 560HP

Posts: 3,029

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by iwantacobra427

I would of used a traditional clutch instead of the hydraulic throwout bearing setup. Also, I would of used a carb that has a choke! If the car sits for more than a day I have to pull the air cleaner and dump some gas down the carb.

|

I'm with Patrick on this one.

Mine sets for up to a month at times in the Winter before I can get it out. All I do is turn the key, turn on the fuel pump and let it fill the carb's for 20 to 30 seconds and start it up.

__________________

John Hall

|

07-18-2009, 11:58 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Silverback51

I'm with Patrick on this one.

Mine sets for up to a month at times in the Winter before I can get it out. All I do is turn the key, turn on the fuel pump and let it fill the carb's for 20 to 30 seconds and start it up.

|

... and I've got a mechanical fuel pump on mine.  Seriously though, except in the dead of winter (when I don't drive it anyway) two or three pumps on the throttle and if it doesn't start within two or three seconds then there's something wrong with it. Now then after that I do have to "feather" the throttle a little bit for about 30 seconds or so before it will idle. A Toyota it is not.  It's usually drivable in three or four minutes from a completely cold start. Now this is a an old-style Holley 4160 Vac. Sec. 750 -- the choke is totally gone. Gone, gone, gone... and never to be found.  |

07-18-2009, 05:31 PM

|

|

CC Member

|

|

|

Join Date: Oct 2004

Location: Odessa,

TX

Cobra Make, Engine: SOLD: ERA FIA #2114 with 331

Posts: 262

|

|

Not Ranked

Not Ranked

I have a mechanical fuel pump feeding a 750 cfm Holley 4150 street HP carb with vac secondaries.

|

07-18-2009, 05:36 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by iwantacobra427

I have a mechanical fuel pump feeding a 750 cfm Holley 4150 street HP carb with vac secondaries.

|

Huh.... Well, try changing out your secondary metering block for the 4160's ultra-high performance metering plate and, maybe... just maybe, all your problems will be solved.  |

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -7. The time now is 01:40 AM.

Links monetized by VigLink

|