Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

March 2026

March 2026

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

| 29 |

30 |

31 |

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

12-27-2009, 06:12 PM

|

|

CC Member

|

|

|

Join Date: Jul 2008

Location: Driftwood,

TX

Cobra Make, Engine: Contemporary Cobra, 427 side oiler

Posts: 1,850

|

|

Not Ranked

Not Ranked

Which Clutch Fork?

Which Clutch Fork?

I have searched a hundred threads to no avail...

I have a 427 FE, TKO 600, Lakewood bellhousing, standard fork that clips into the BH driver's side pivot and the McLeod sealed TO bearing that clips on the end of the fork. I have been using a rear-mounted pull-type Wilwood slave which I do not like. I want to go with a block-mounted slave and keep the driver's side clutch arm and TO bearing. The arm I have was cut and drilled to suit the Wilwood slave, so I don't know if it would have been the right length for such a setup. Can anyone tell me which fork I need that will snap into the BH pivot and line up with the path of the block mounted slave?

Thanks.

Last edited by elmariachi; 12-27-2009 at 06:34 PM..

|

-

Advertising

12-27-2009, 07:02 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Jim,

Brent Lykins or Mike Forte should be able to help.

__________________

Chas.

|

12-27-2009, 07:08 PM

|

|

CC Member

|

|

|

Join Date: Jul 2008

Location: Driftwood,

TX

Cobra Make, Engine: Contemporary Cobra, 427 side oiler

Posts: 1,850

|

|

Not Ranked

Not Ranked

I have pinged Brent, waiting on a reply. Thx.

|

01-05-2010, 10:11 PM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: San Jose CA,

CA

Cobra Make, Engine: SPF_R_/BRG/FRBoss302/327CI/FordEFI/Under_Car_Exh/

Posts: 2,523

|

|

Not Ranked

Not Ranked

Elmar-, - to move from a conventional rearward traveling arm-fork to disengage the clutch , to a forward traveling arm-fork so we can reuse your willwood cylinder; one needs to move the location of the pivot ball in the bell-housing from the drivers side (US) to the passenger side (US) and get the correct fork.

I would try the 5.0L fork. -- you can get a beefy version if you want to but we have had good luck with the stock ford units.

Steve

PS I think your BH setup may be already drilled for the PS pivot ball.

__________________

Steve SPF 2734 MK3 / Brock Coupe #54- panavia.com

Last edited by PANAVIA; 01-05-2010 at 10:18 PM..

|

01-06-2010, 06:26 AM

|

|

Stolen Avitar

|

|

|

Join Date: Oct 2004

Location: Brunswick,

GA

Cobra Make, Engine: BDR 1311 428PI

Posts: 3,044

|

|

Not Ranked

Not Ranked

Steve, I don't think he's changing the clutch release arm direction of travel, he's just changing from a pull type slave to a push type slave. Release arm direction of travel will be the same.

other Steve

|

01-06-2010, 07:55 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Nov 2006

Location: Charleston,

WV

Cobra Make, Engine: SPF 2592, Shelby alum. 527

Posts: 325

|

|

Not Ranked

Not Ranked

Sounds like my installation is the same as what you want.

My push-type slave cylinder bolts to a machined aluminum bracket (supplied by Superformance as part of their install kit) that bolts to the driver side of the Lakewood bellhousing (using the bellhousing-to-block attachment bolts), adjacent to the fork opening in the bellhousing.

Slave cylinder: Wagner F124111

Clutch fork: Dorman 14553

Throwout bearing: Federal Mogul FB-1625-C

Hope this helps.

Rodger

|

01-06-2010, 09:23 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

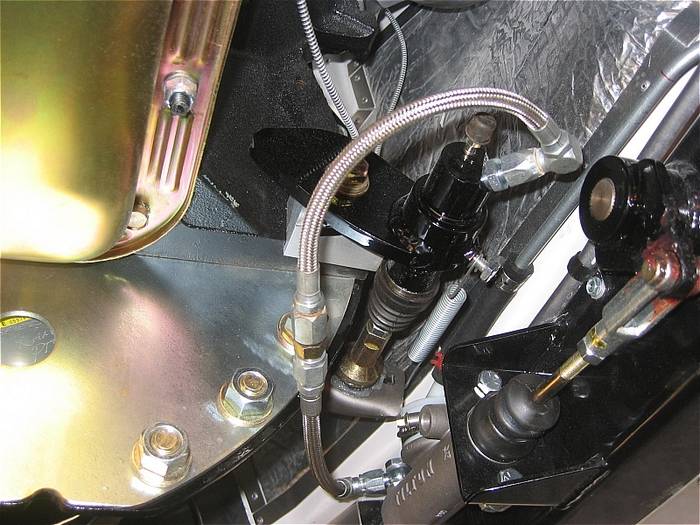

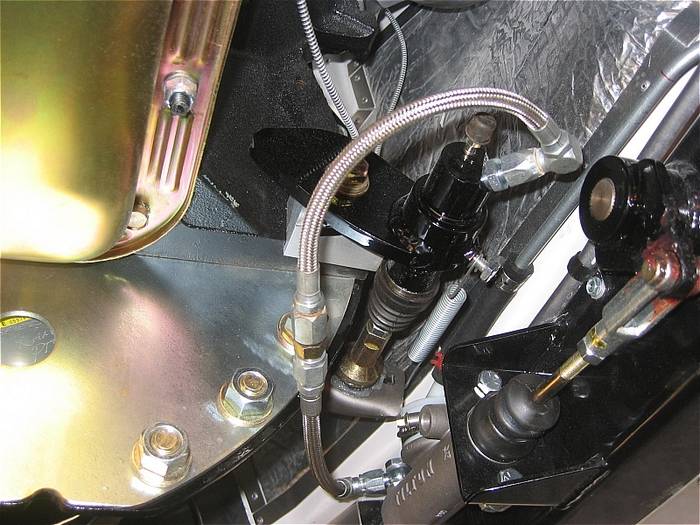

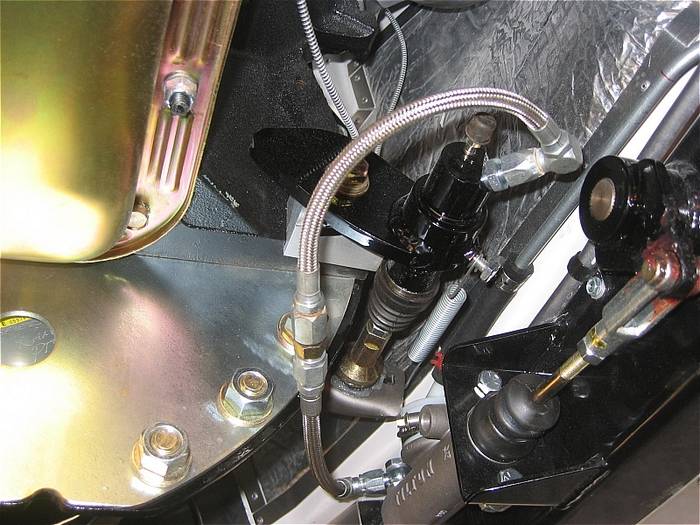

El, with my Lakewood, TKO600, FE combo I use the Ford D0TZ-7515A clutch fork with a hole drilled in the end of the fork so the slave-to-fork rod distance can be easily adjusted (drilling that hole is a job for the machine shop, btw). Note that in my photo below that in order to get the slave to line up properly with the fork an aluminum spacer was used (probably similar to what RodgerH was writing about above). The D0TZ-7515A is available from RockAuto for less that $20.

http://www.rockauto.com/dbphp/x,cata...ATP_ZA101.html

|

01-06-2010, 09:34 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Shot from the Rear

Shot from the Rear

Here's a shot from the rear. I took this pic last year when we were all checking the torque on the pressure plate bolts on our aluminum flywheels (I know you remember that thread  ).

Last edited by patrickt; 11-08-2016 at 01:35 PM..

|

01-06-2010, 09:48 AM

|

|

Stolen Avitar

|

|

|

Join Date: Oct 2004

Location: Brunswick,

GA

Cobra Make, Engine: BDR 1311 428PI

Posts: 3,044

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

Ford D0TZ-7515A clutch fork with a hole drilled in the end of the fork so the slave-to-fork rod distance can be easily adjusted (drilling that hole is a job for the machine shop, btw

|

Patrick, I have to ask; why the machine shop?

Steve |

01-06-2010, 09:53 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by lovehamr

Patrick, I have to ask; why the machine shop?

Steve

|

The part is case hardened and ( uhh, at least for people like me) dropping it off at a machine shop that can cleanly drill through that type of hardened metal is the way to go. |

01-06-2010, 08:23 PM

|

|

CC Member

|

|

|

Join Date: Jul 2008

Location: Driftwood,

TX

Cobra Make, Engine: Contemporary Cobra, 427 side oiler

Posts: 1,850

|

|

Not Ranked

Not Ranked

Yep, this is what I am trying to get to, a custom spacer to facilitate a block-mounted slave.

To use the frame-anchored Wilwood, I had to drill a hole in the end of the fork and after ruining a few bits I too had to use my machinist. Its some super-hard steel.

|

01-06-2010, 08:44 PM

|

|

CC Member / Sponsor

|

|

|

Join Date: Oct 2003

Cobra Make, Engine:

Posts: 808

|

|

Not Ranked

Not Ranked

El,

I have several setups for you to try. But why not a hyd. throw out bearing? It looks very tight on the engine side of your setup. It would simplify your set up and since you are changing transmissions. The lakewood bellhousing is very big in there as well, have you seen the Quick Time Bellhousings. These are the best I have used so far. If you go with a hyd throw bearing I would suggest a Tilton and a Tilton bearing adapter. Just my .02 worth.

Bill

__________________

Squeaky wheel always gets the grease!!

www.gcperf.com

|

01-07-2010, 05:32 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by elmariachi

Yep, this is what I am trying to get to, a custom spacer to facilitate a block-mounted slave.

|

When faced with similar challenges, I use a block of soft wood and then cut it, notch it, whittle it, and drill it until it's perfect (often times going through more than one block of wood). Then I drop the block of wood off at my friendly neighborhood machine shop who does the real work on a real piece of metal. |

01-07-2010, 08:17 AM

|

|

CC Member

|

|

|

Join Date: Jul 2008

Location: Driftwood,

TX

Cobra Make, Engine: Contemporary Cobra, 427 side oiler

Posts: 1,850

|

|

Not Ranked

Not Ranked

I am actually not changing transmissions, I just have mine out while replacing the leaking pan gaskets. I would rather not scrap a perfectly good Lakewood, and am not fond of hydraulic TO bearings. At present the Wilwood is anchored to the frame so when the engine moves from torque, I suppose there is a slight possibility it could move the fork, though I have had no signs of slipping. But the setup is bugging me anyway. The easiest solution would be the same as you ERA and Backdraft guys are using with the old-style push slave mounted to the engine via bracket.

I have a machine shop that I use regularly and he has looked at it and offered to make a bracket. But it will take him time to get to it and I was hoping to do it while I had use of the shop lift.

|

01-07-2010, 12:45 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by elmariachi

I have a machine shop that I use regularly and he has looked at it and offered to make a bracket. But it will take him time to get to it and I was hoping to do it while I had use of the shop lift.

|

It will take you ten minutes with a bar of soap and a pocket knife to fabricate the spacer on any decent FE block-slave bracket. I'll bet your machinist has had somebody bring him a whittled bar of soap before, too. |

01-07-2010, 03:20 PM

|

|

CC Member / Sponsor

|

|

|

Join Date: Oct 2003

Cobra Make, Engine:

Posts: 808

|

|

Not Ranked

Not Ranked

El,

Yes I still use a push style, but not from the engine side.

Bill

__________________

Squeaky wheel always gets the grease!!

www.gcperf.com

|

01-07-2010, 04:08 PM

|

|

CC Member

|

|

|

Join Date: Jul 2008

Location: Driftwood,

TX

Cobra Make, Engine: Contemporary Cobra, 427 side oiler

Posts: 1,850

|

|

Not Ranked

Not Ranked

Bill you've got another email.

Jim

|

01-11-2010, 02:15 AM

|

|

CC Member

|

|

|

Join Date: May 2008

Location: San Jose CA,

CA

Cobra Make, Engine: SPF_R_/BRG/FRBoss302/327CI/FordEFI/Under_Car_Exh/

Posts: 2,523

|

|

Not Ranked

Not Ranked

I was thinking about this more -

- and it might make sense to have a pull-type fork in an FE setup.

it would allow the use of nice diaphragm clutches, nice clutch release bearings and would open up your selection of release forks.

not to mention tunnel clearance - fork moves forward to disengage clutch using the bell-housing tunnel area for fork movement.

Let me look at this and advise.

__________________

Steve SPF 2734 MK3 / Brock Coupe #54- panavia.com

|

01-17-2010, 06:06 AM

|

|

CC Member

|

|

|

Join Date: Jan 2002

Location: Lakeland,

FL

Cobra Make, Engine: ERA 427SC FMS 351W

Posts: 199

|

|

Not Ranked

Not Ranked

Pictures of Superperformance slave mount???

Pictures of Superperformance slave mount???

RodgerH,

I would like to see the slave cylinder set-up you decribed. Have you posted any pics? What about others with the same Superperformance set-up?

Thanks in advance

|

02-10-2010, 10:44 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Nov 2006

Location: Charleston,

WV

Cobra Make, Engine: SPF 2592, Shelby alum. 527

Posts: 325

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

El, with my Lakewood, TKO600, FE combo I use the Ford D0TZ-7515A clutch fork with a hole drilled in the end of the fork so the slave-to-fork rod distance can be easily adjusted (drilling that hole is a job for the machine shop, btw). Note that in my photo below that in order to get the slave to line up properly with the fork an aluminum spacer was used (probably similar to what RodgerH was writing about above). The D0TZ-7515A is available from RockAuto for less that $20.

http://www.rockauto.com/dbphp/x,cata...ATP_ZA101.html

|

Patrick,

Do you have the p/n (or a source) for the pivot seat you used with your clutch fork? I checked with the local Ford garage and with RockAuto...both showed the fork you referred to, but neither had a reference to the pivot. The spring broke on my fork and I'm considering a different style.

Also, could you go into a little details on the fabrication of your adjustable clutch pushrod?

Thanks,

Rodger |

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 04:35 AM.

|

).

).

Linear Mode

Linear Mode