Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

March 2026

March 2026

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

| 29 |

30 |

31 |

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

02-10-2010, 12:33 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by RodgerH

Do you have the p/n (or a source) for the pivot seat you used with your clutch fork?

|

I have a Lakewood 15210 Bellhousing. The pivot ball is the Lakewood Adjustable Clutch Fork Pivot Ball for that item. Here is the page: http://www.lakewoodindustries.com/Pr...minselection=6

Quote:

Originally Posted by RodgerH

Also, could you go into a little details on the fabrication of your adjustable clutch pushrod?

|

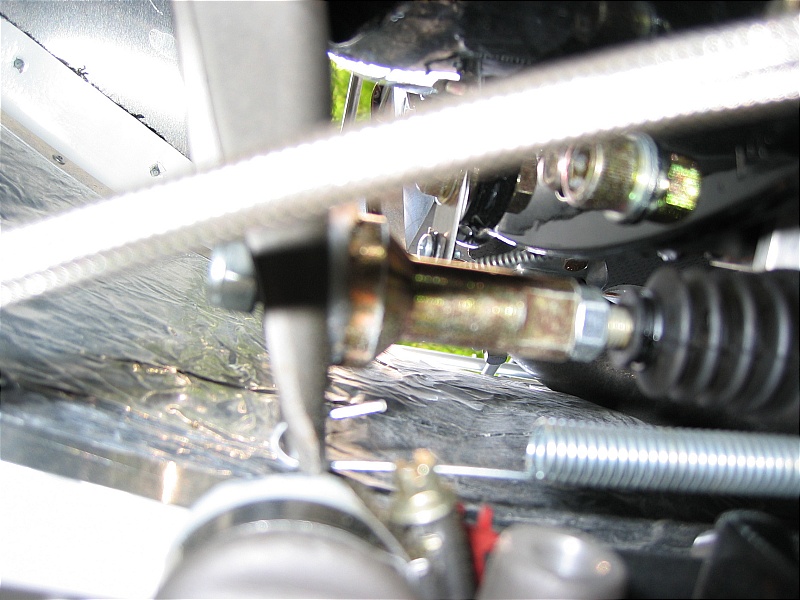

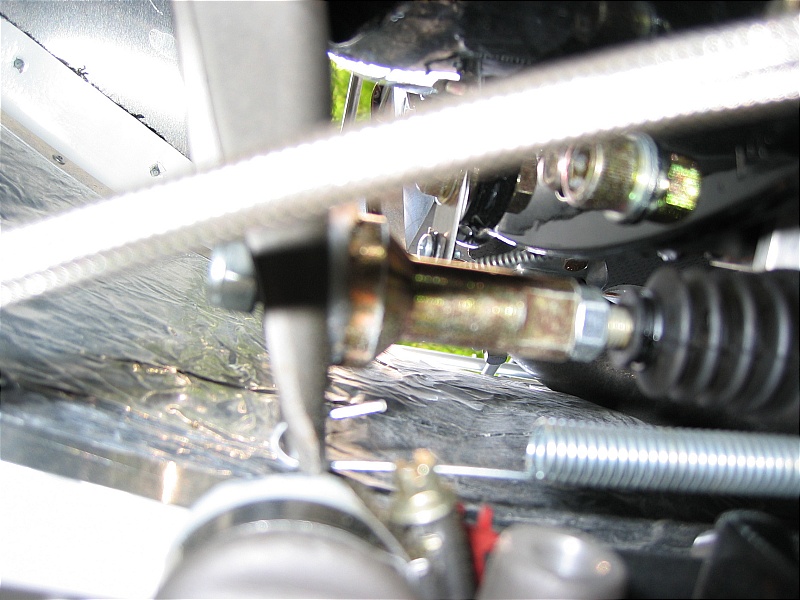

You use a threaded rod coming out of the slave cylinder. The threaded rod pass completely though a larger piece that will make contact with the clutch fork. It is brass colored in the photo below. You can also see a silver locknut that holds the brass piece locked in place. The threaded rod passes all the way through the clutch fork via a hole that you must drill in the fork itself. You can place another nut on the threaded rod behind the clutch fork to ensure that it does not pop out of the fork on really fast shifts. Thus, everything is adjustable on the threaded rod.

Last edited by patrickt; 11-08-2016 at 01:36 PM..

|

-

Advertising

02-10-2010, 02:08 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Clarity

Clarity

Just to be extra clear, the brass colored piece that comes in direct contact with the clutch fork is also threaded (it is not smooth-bored around the threaded rod). Thus you turn that brass colored piece while holding the threaded rod to adjust its proximity to the fork. This older post of mine has more detailed instructions on adjusting the clutch: Clutch Adjustments |

02-10-2010, 02:28 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Nov 2006

Location: Charleston,

WV

Cobra Make, Engine: SPF 2592, Shelby alum. 527

Posts: 325

|

|

Not Ranked

Not Ranked

Thanks Patrick. Did the brass colored piece come from ERA?

|

02-10-2010, 02:35 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by RodgerH

Thanks Patrick. Did the brass colored piece come from ERA?

|

Yes, but it doesn't appear to be anything terribly special. You could undoubtedly find something just as suitable at a plumbing supply store. |

02-10-2010, 02:54 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Nov 2006

Location: Charleston,

WV

Cobra Make, Engine: SPF 2592, Shelby alum. 527

Posts: 325

|

|

Not Ranked

Not Ranked

Ok....thanks. Presently I'm using a rod with a rounded tip. A spring (same as in your pictures) holds it tight against the slave piston. Only problem is the rod length adjustment is at the slave cylinder end of the rod, so I have to slide the boot back to get to get to it. I may do something similar to your setup.

Rodger

|

02-10-2010, 03:39 PM

|

|

Stolen Avitar

|

|

|

Join Date: Oct 2004

Location: Brunswick,

GA

Cobra Make, Engine: BDR 1311 428PI

Posts: 3,044

|

|

Not Ranked

Not Ranked

|

02-10-2010, 03:54 PM

|

|

CC Member

|

|

|

Join Date: Apr 1999

Location: cleveland,

OH

Cobra Make, Engine: CSX4000, 427

Posts: 1,999

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by RodgerH

Do you have the p/n (or a source) for the pivot seat you used with your clutch fork? I checked with the local Ford garage and with RockAuto...both showed the fork you referred to, but neither had a reference to the pivot. The spring broke on my fork and I'm considering a different style.

Also, could you go into a little details on the fabrication of your adjustable clutch pushrod?

|

I used a BBC rocker pivot, slid over a hardened threaded rod ( from a leaf spring clamping U bolt ) with two jam nuts behind the rocker pivot. I ground the other end of the rod to a rounded shape that went into the seat inside the slave cylinder.

__________________

"After jumping into an early lead, Miles pitted for no reason. He let the entire field go by before re-entering the race. The crowd was jumping up and down as he stunned the Chevrolet drivers by easily passing the entire field to finish second behind MacDonald's other team Cobra. The Corvette people were completely demoralized."

|

02-10-2010, 05:07 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by lovehamr

Here's what I'm using w/my FE. It's a modified bracket from Bill, push type cylinder, TKO, late model type clutch "fork" and QT bellhousing.

|

LoveHamr, how do you adjust the slave to fork distance as the clutch wears? With shims on the slave itself? Or is the rod somehow adjustable and I just can't see it because I have snow-blindness? |

02-10-2010, 07:30 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

Yes, but it doesn't appear to be anything terribly special. You could undoubtedly find something just as suitable at a plumbing supply store.

|

I have that same ball-end piece and I'm not positive Pat but that may be a specially hardened steel piece with cad plate-it is NOT brass. They machined it beautifully. I would not advise hardware store stuff on a piece that resists friction of 200-300 pound force and is used countless times per drive...

__________________

Chas.

|

02-10-2010, 07:35 PM

|

|

Stolen Avitar

|

|

|

Join Date: Oct 2004

Location: Brunswick,

GA

Cobra Make, Engine: BDR 1311 428PI

Posts: 3,044

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

LoveHamr, how do you adjust the slave to fork distance as the clutch wears? With shims on the slave itself? Or is the rod somehow adjustable and I just can't see it because I have snow-blindness?

|

Actually I have 2 different push rods, one is a threaded type. Once the car is running I'll try both and see how things work out. The cylinder seems to have a very long throw.

Steve |

02-10-2010, 08:04 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by ERA Chas

I have that same ball-end piece and I'm not positive Pat but that may be a specially hardened steel piece with cad plate-it is NOT brass. They machined it beautifully. I would not advise hardware store stuff on a piece that resists friction of 200-300 pound force and is used countless times per drive...

|

Yes, you're right on that Chas. So, I'll take it back.  |

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 09:55 AM.

|

Linear Mode

Linear Mode