Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

|

CC Advertisers

CC Advertisers

|

|

09-05-2015, 07:44 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by davids2toys

Patrick,

Concerning this wire. I read somewhere else in the from that you installed another ground wire from the manifold to this same location as the black wire. Was that in addition to the black wire or instead?

As far as doing this test, was that with the car running and progressively turning on all the accessories one by one and you watch your amperage grow the more you turned on.

OK,. so I only have a multi-meter, no inductive ammeter. Can I just break the connection and run it thru the multimeter to get the reading?

Thanks...Dave

|

That strap was a supplemental ground that was in addition to the black ERA ground wire. Yes, I turned on my lights and fans and then measured the current running through that wire and it seemed a bit high. You can not just disconnect the wire and run it in series with your multimeter unless you have a very special multimeter that will measure higher amperage. Most multimeters can only measure very tiny amounts of current that way. |

09-06-2015, 05:22 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: E BRUNSWICK N.J. USA,

Posts: 3,841

|

|

Not Ranked

Not Ranked

Phil Stop breakin the car

Phil Stop breakin the car

Large Arbor Phil if you are having starter problems and have a good battery and starter here's the problem with eating teeth on the flywheel

I had the same problem with a shelby block motor, 3 choices

I don't know which bellhousing you have but if it's a lake wood your mini starter doesn't have enough extendion for full engagement. Does your bell housing have a block protector plate? If yes You need to remove where the starter goes through the hole area and have the starter mount to the bell housing directly. I sabre sawed mine with a metal blade. The thing with this is checking the starter to make sure it is not hitting or rubbing on the block. I had to grind a little of the block to clear this too. Also and this is BIG, Make sure the bellhousing is centered on the block. Alot of problems happen from this not being done. This includes Stock bellhousing and Quicktime or any other ones. Mine with .038" out. After 3 hours of trimming and adjusting I Got it down to .003" max spec is about .005-.007" out of center.I have found that allen head bolt on the blind side of the starter work the best.

Once we know we have the starter mounted deeper for more full contact we need to look at the air gap between the teeth of starter and flywheel. You want about.035". The easy way is to just use the flywheel without the clutch and ingage just the soleniod of the motor. A large paper clip is the correct thickness. You should be able to stick this between the 2 teeth. You don't have to be perfect but in the ball park. The wider the gap the more stress on the teeth of the flywheel. This job is a pain in the A$$. As for the flywheel, you can have just the teeth replace. If the flywheel has been worked hard with cracks and burnt marks, replace it.

I starter with a Tilton starter and worn out 2 drives before finding out what was causing this failure. It's a pain in the butt to jump start the car.

Other side note, if you are running a Lakewood bell housing and a GM input shaft trans, measure the depth of the input to the back of the block. In some cases you have to remove .280" off where the tip goes into the bushing or bearing in the back of the crankshaft. IF you don't you WILL wear out the thrust bearing permaturily. The is a small side note in the instructions from Lake wood on this for FE motors. Not sure about other Ford motors.

The other fix is to go old style starter and hope you have a strong one and heavy cables to handle the 150-250 amp draw on starting the motor. The OEM starters can be a pain in the butt when they are heat soaked for a long drive and will barely crank the motor over. This is the main reason for the mini gear reduction starters and they draw only 70-120 amps.

The last choice is to have the starter mounting surface machined about .250" and this will give you the added extension on the drive to give you almost a full contact area and stop breaking the teeth on the flywheel. Sammy here on CC has done this and it worked good. The only thing a don't like is the fact of a thin mounting surface with 3 small bolts to hold and control the torque twist when starting the motor. If you have a problem down the road with this starter, need to have it machined again to fit and work correctly. This is the best info I have on this problem. Good luck Rick L.

|

09-06-2015, 12:59 PM

|

|

CC Member

|

|

|

Join Date: Dec 2006

Location: Southbury,

ct

Cobra Make, Engine: ERA, 428, 4 speed Toploader, Jag rear, Red with White stripes

Posts: 945

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

That strap was a supplemental ground that was in addition to the black ERA ground wire. Yes, I turned on my lights and fans and then measured the current running through that wire and it seemed a bit high. You can not just disconnect the wire and run it in series with your multimeter unless you have a very special multimeter that will measure higher amperage. Most multimeters can only measure very tiny amounts of current that way.

|

Oh that sucks!

So I need this inductive type to measure higher amps? I think my multi-meter is supposed to measure 10 amps unfused.

So was this with the car running or not running?

__________________

ERA#698 428, 4 speed Toploader, 3:31 Jag rear

|

09-07-2015, 10:13 PM

|

|

CC Member

|

|

|

Join Date: Dec 2006

Location: Southbury,

ct

Cobra Make, Engine: ERA, 428, 4 speed Toploader, Jag rear, Red with White stripes

Posts: 945

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

That strap was a supplemental ground that was in addition to the black ERA ground wire. Yes, I turned on my lights and fans and then measured the current running through that wire and it seemed a bit high. You can not just disconnect the wire and run it in series with your multimeter unless you have a very special multimeter that will measure higher amperage. Most multimeters can only measure very tiny amounts of current that way.

|

That braided strap had to have two different ends. The one for the firewall is only 1/4', the manifold bolts are way bigger requiring a bigger eyelet. Do you recall where you got the cable?. I see a lot of companies sell cables in bulk, but I cant find much info on putting on your own custom terminals.

__________________

ERA#698 428, 4 speed Toploader, 3:31 Jag rear

|

09-08-2015, 10:32 PM

|

|

CC Member

|

|

|

Join Date: Dec 2006

Location: Southbury,

ct

Cobra Make, Engine: ERA, 428, 4 speed Toploader, Jag rear, Red with White stripes

Posts: 945

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

That strap was a supplemental ground that was in addition to the black ERA ground wire. Yes, I turned on my lights and fans and then measured the current running through that wire and it seemed a bit high. You can not just disconnect the wire and run it in series with your multimeter unless you have a very special multimeter that will measure higher amperage. Most multimeters can only measure very tiny amounts of current that way.

|

Thanks for the strap info..I will check them out and see what they have.

I borrowed a friends big Snap on Amp reading tool, here is a pic.

After I figure it out I started testing all kinds of stuff. At first I could not get it to work.. but when I put it across a few fuses and got readings, I went back to the wire. Seems the key has to be on to get a reading on the wire, but not on the fuses. With the big snap on gauge I got a little less than 2 amps with the wipers, high beams, and fan on. No horn, blinkers or brake lights After I realized I would not blow my multi-meter I did it with that and the most I got was .07 ish, it was jumping around a little. I don't know why the discrepancy between the two gages?

What would you consider to be normal here? I'm thinking nothing should be running thru that wire?

__________________

ERA#698 428, 4 speed Toploader, 3:31 Jag rear

Last edited by davids2toys; 09-08-2015 at 10:47 PM..

|

03-31-2014, 11:00 AM

|

|

CC Member

|

|

|

Join Date: Nov 1999

Location: White Plains,,

NY

Cobra Make, Engine: ERA140, ERA 267, ERA GT2038, ERA FIA 2045, ERAGT2077 ERA2893000EXP

Posts: 1,117

|

|

Not Ranked

Not Ranked

In addition to the ground running from the pass side head to a bolt into the steel support behind the firewall, I always have a large ground strap running from the back of the transmission to the frame. See: Mallory 28135 Universal Ground Strap - Rakuten.com Shopping |

03-31-2014, 11:05 AM

|

|

CC Member

|

|

|

Join Date: Dec 2011

Location: West Chester,

PA

Cobra Make, Engine: ERA #795 427 S/C completed Jan. '14 - '68 FE 427 side oiler

Posts: 1,060

|

|

Not Ranked

Not Ranked

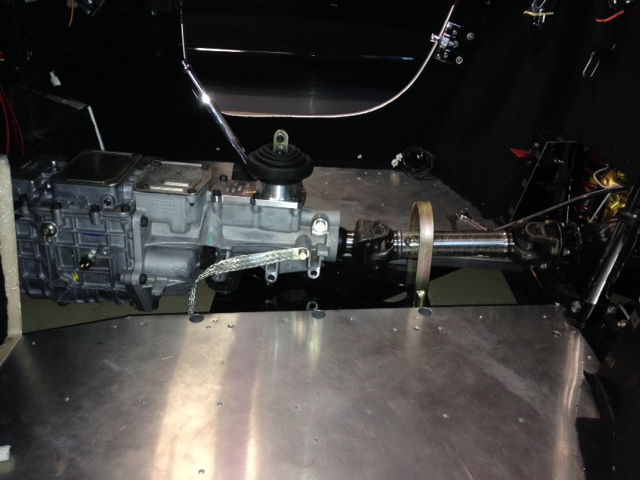

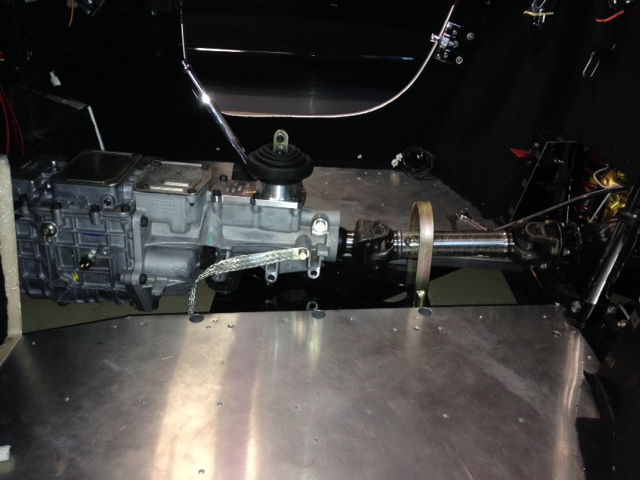

The ground strap that Jim is referring to came with my ERA, so check to see that it is there and is tightly connected. You can see it in the center foreground in the photo bleow.

__________________

"Anyone who drives faster than you is a maniac and anyone who drives slower than you is an idiot" - George Carlin

|

03-31-2014, 04:29 PM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,533

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by kevins2

The ground strap that Jim is referring to came with my ERA, so check to see that it is there and is tightly connected. You can see it in the center foreground in the photo bleow.

|

It's kind of strange - but mine didn't come with a ground strap for the transmission. I assumed it was because of the cast iron toploader transmission.  |

03-31-2014, 05:41 PM

|

|

CC Member

|

|

|

Join Date: Nov 2003

Location: New Britain,

CT

Cobra Make, Engine: Size 10 Feet

Posts: 3,032

|

|

Not Ranked

Not Ranked

There should be a large ground cable from the engine to the chassis or battery negative somewhere. If the battery is mounted in the engine compartment, we might run a ground directly between the battery negative and the block.

|

04-01-2014, 06:00 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,533

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by strictlypersonl

There should be a large ground cable from the engine to the chassis or battery negative somewhere. If the battery is mounted in the engine compartment, we might run a ground directly between the battery negative and the block.

|

My battery negative post cable is bolted to the engine block and the black wire from near the starter relay in Patrick's post is bolted to the engine also. There weren't any other grounding straps in the wiring kit. I have grounds to the frame at the front X-member, behind the dash, tailights, headlights (I think). I guess I will pick up a strap and secure between the engine/trans and the frame somewhere. |

04-02-2014, 07:50 PM

|

|

CC Member

|

|

|

Join Date: Oct 2013

Location: Columbus,

OH

Cobra Make, Engine: ERA 714

Posts: 713

|

|

Not Ranked

Not Ranked

So we repaired it but it still does not sound right. Ordered a Powermaster 9406 and it should arrive next week. I'll keep the old one around and hopefully won't have any further issues.

Oh yes, I found the grounds. Tightened bolts, etc.

Phil

|

04-03-2014, 07:04 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Mar 2000

Location: St. Augustine,

FL

Cobra Make, Engine: E-M / Power Performance / 521 stroker / Holley HP EFI

Posts: 1,947

|

|

Not Ranked

Not Ranked

Phil,

Sorry late on this thread. Here's a little history of the "Click of Doom."

If you want to go to the solution directly, go here: Adding a Remote Starter Solenoid to your Chevy, My Way

If you're up for some history, start here, noting the different Ford solenoids and their reliability: First Coast Cobra Club • View topic - Tom's starter CLICK of doom. Solved?

and then make your way to the last message here: First Coast Cobra Club • View topic - Zephyr update June 2011

The final solution, dual solenoids, has worked on the Cobra and the Zephyr for nearly three years and many thousands of miles for each car.

Hope this is of some help,

Tom

__________________

Wells's law of engine size: If it matters what gear you're in, the engine's too small!

|

03-31-2014, 06:54 PM

|

|

CC Member

|

|

|

Join Date: Nov 1999

Location: White Plains,,

NY

Cobra Make, Engine: ERA140, ERA 267, ERA GT2038, ERA FIA 2045, ERAGT2077 ERA2893000EXP

Posts: 1,117

|

|

Not Ranked

Not Ranked

A braided ground strap can be had for under $20. I would recommend the trans-frame connection even where the battery is on the right footbox and there is a direct connection to the block. With a fiberglass body and rubber motor mounts, more is better...

Jim

|

04-03-2014, 05:05 PM

|

|

CC Member

|

|

|

Join Date: Oct 2013

Location: Columbus,

OH

Cobra Make, Engine: ERA 714

Posts: 713

|

|

Not Ranked

Not Ranked

Tom,

Thanks for the post. The old CVR has a solenoid on it and I have one on the dash the same as Pat's shown above. I ordered a Powermaster 9406 and we'll see how it works. If this is the worst thing I have to replace, I will be a happy camper.

Phil

|

04-04-2014, 06:35 PM

|

|

CC Member

|

|

|

Join Date: Oct 2013

Location: Columbus,

OH

Cobra Make, Engine: ERA 714

Posts: 713

|

|

Not Ranked

Not Ranked

Ok, so the saga continues. The repaired starter did not sound right and when I pulled it, it had a missing tooth. My guess is it did not disengage the full amount and broke a tooth. Flywheel looks ok. I bought a Powermaster 9406 per the ERA manual and the bolt holes do not line up to a Shelby Aluminum Block. The adjustments do not allow enough movement to make them align. There was only about 3 adjustment locations. So I am off to the parts store in the a.m. to buy another CVR like the old one.

Phil

|

04-04-2014, 07:16 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Large Arbor

Ok, so the saga continues. The repaired starter did not sound right and when I pulled it, it had a missing tooth. My guess is it did not disengage the full amount and broke a tooth. Flywheel looks ok. I bought a Powermaster 9406 per the ERA manual and the bolt holes do not line up to a Shelby Aluminum Block. The adjustments do not allow enough movement to make them align. There was only about 3 adjustment locations. So I am off to the parts store in the a.m. to buy another CVR like the old one.

Phil

|

You know a lot of us, both here and on the FE forum, use the OEM big-ass starter motor. You can still get them at Pep Boys and the like for about $50. |

04-05-2014, 07:00 PM

|

|

CC Member

|

|

|

Join Date: Oct 2013

Location: Columbus,

OH

Cobra Make, Engine: ERA 714

Posts: 713

|

|

Not Ranked

Not Ranked

New CVR starter 5049M is in and works like a charm! Done!!!

Phil

|

04-08-2014, 11:10 AM

|

|

CC Member

|

|

|

Join Date: Oct 2013

Location: Columbus,

OH

Cobra Make, Engine: ERA 714

Posts: 713

|

|

Not Ranked

Not Ranked

The two starters are shown below. The Powermaster 9406 does not have enough adjustment on mounting holes for my Bell Housing. The CVR has 360 degrees of adjustment. Pics below.

Phil |

05-03-2015, 06:51 PM

|

|

CC Member

|

|

|

Join Date: Oct 2013

Location: Columbus,

OH

Cobra Make, Engine: ERA 714

Posts: 713

|

|

Not Ranked

Not Ranked

It looks like I need to revisit this as my starting symptoms have returned. I used a Robb MC starter which appears to have lasted about a year and so I will have to pull it out and look to see if it ate teeth on the ring gear. I am not sure what to do next if this is the case. Perhaps larger bolts, but I think the Robb MC started did not have enough HP to last.

Phil

|

09-10-2015, 07:11 AM

|

|

CC Member

|

|

|

Join Date: Dec 2006

Location: Southbury,

ct

Cobra Make, Engine: ERA, 428, 4 speed Toploader, Jag rear, Red with White stripes

Posts: 945

|

|

Not Ranked

Not Ranked

Yes, I understand this and that is exactly what I did for this ground wire. However , when testing the CB from the Alternator thread Alternator / Voltage Regulator , I just went from stud to stud and disconnected no wires. . I guess my thinking was I just wanted to see what was running thru the breaker. Maybe that is why the very low reading. I will post this last part on that thread to avoid confusion to future readers.

__________________

ERA#698 428, 4 speed Toploader, 3:31 Jag rear

|

| Thread Tools |

|

|

| Display Modes |

Hybrid Mode Hybrid Mode

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 05:11 AM.

Links monetized by VigLink

|