Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

1 |

2 |

3 |

4 |

| 5 |

6 |

7 |

8 |

9 |

10 |

11 |

| 12 |

13 |

14 |

15 |

16 |

17 |

18 |

| 19 |

20 |

21 |

22 |

23 |

24 |

25 |

| 26 |

27 |

28 |

29 |

30 |

31 |

|

|

CC Advertisers

CC Advertisers

|

|

11Likes 11Likes

06-15-2014, 04:13 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Lykins Motorsports 438W Build

Lykins Motorsports 438W Build

This build is getting ready to get underway. This one is for jhv48, a fellow Club Cobra member.

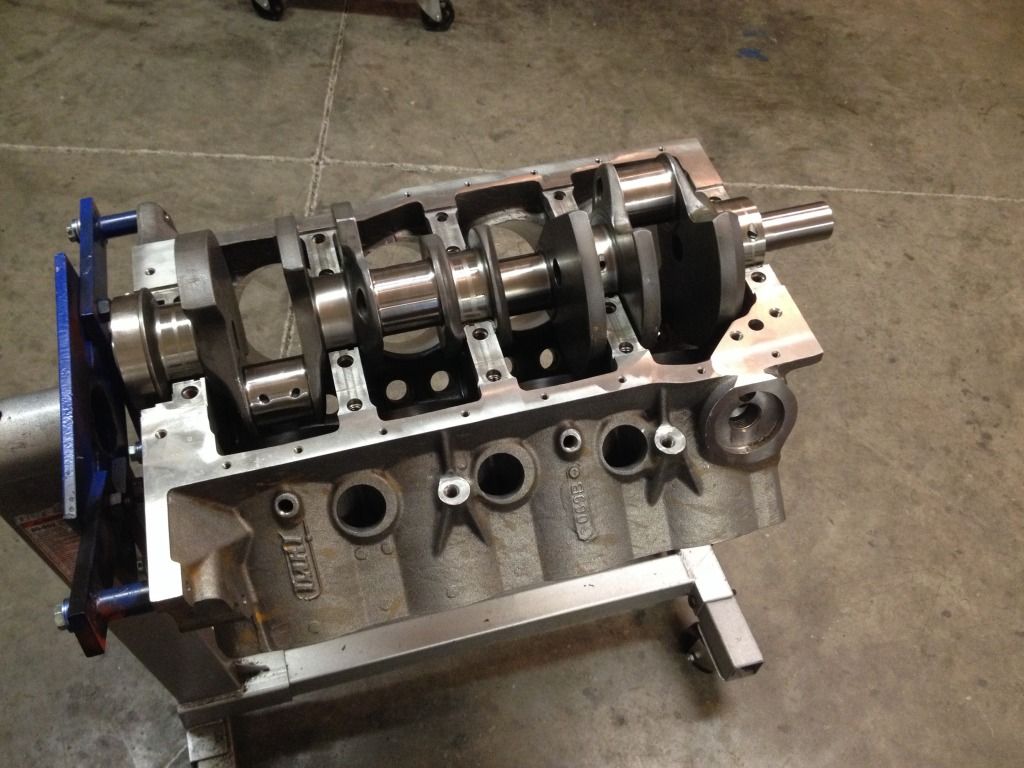

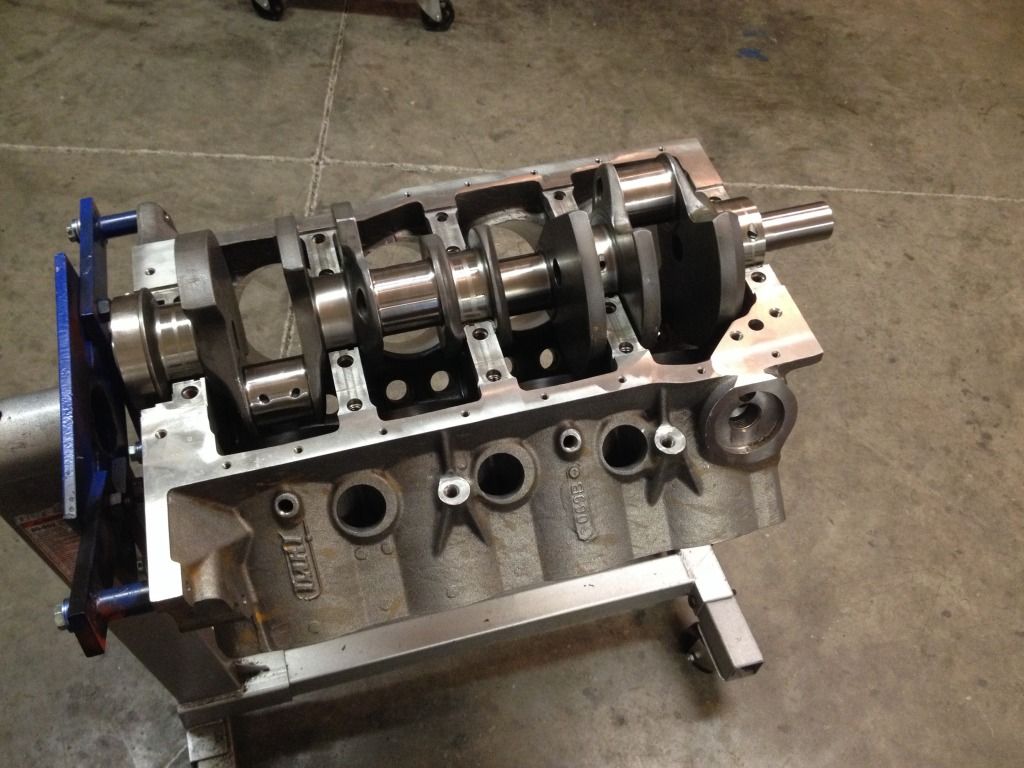

Picking up the block tomorrow, a Dart SHP, 9.500" deck, 4.125" bore. The crank is a Scat 4340 piece, 4.100" stroke. Rods are Scat I-beams, 6.200" length, and they are going to be pinned to a set of Diamond pistons.

We chose a set of the newer 220cc AFR Renegade heads with 58cc chambers. I've had them for several weeks and have already assembled them with Comp Cams springs and retainers. I'm an AFR and TFS fan, and I really like the parts that AFR sends with these heads: 8mm valves, adjustable guideplates, etc. All good stuff.

The cam is a Bullet hydraulic roller, 240/246 @ .050", 110/104, .624/.630 lift.

The intake manifold is an Edelbrock Performer RPM Air Gap, that's been "massaged."

Gratuitous assembled head shot...

|

06-15-2014, 04:31 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

That cam is a near twin to mine in the 427 FE. Excellent for that size motor and a ton of breathing from 3500 up. My heads are 320 cfm; what are these rated Brent?

__________________

Chas.

|

06-15-2014, 04:42 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

About that at .600".

|

06-15-2014, 06:52 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Yes-forgot to say-mine too.

58cc chambers, did you spec pistons for 10.8:1? I'm a little softer at 10.33

You planning a 950 on that modified Air Gap? I ran a lot of CFM at WOT and it worked. You'll have better velocity with 2.08's vs my 2.250's.

Bet you'll make 560+.

__________________

Chas.

|

06-16-2014, 02:56 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by ERA Chas

Yes-forgot to say-mine too.

58cc chambers, did you spec pistons for 10.8:1? I'm a little softer at 10.33

You planning a 950 on that modified Air Gap? I ran a lot of CFM at WOT and it worked. You'll have better velocity with 2.08's vs my 2.250's.

Bet you'll make 560+.

|

These are 2.100" intake valves. Engine is going to California, the land of bad pump gas, so SCR is more closer to 10:1. It's getting a Quick Fuel Q-850, which is more than adequate for an engine of this size. Jim has focused on streetability and manners.

It won't make 560+ on this dyno. I've done several of these with the hydraulic rollers and they're generally at around 525-550 depending on the cam and intake work.

vatdevil, the Air Gap is actually a very nice intake manifold, even for a big inch Windsor, especially when they have plenum and runner work on them. |

08-02-2014, 06:18 AM

|

|

CC Member

|

|

|

Join Date: Nov 1999

Location: Brisbane, Australia,

Q

Cobra Make, Engine: Contemporary CCX3117 427FE

Posts: 4,381

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by blykins

It won't make 560+ on this dyno. I've done several of these with the hydraulic rollers and they're generally at around 525-550 depending on the cam and intake work.

|

Right on! Looks like a really nice street combination.

__________________

Craig

|

06-16-2014, 02:35 AM

|

|

CC Member

|

|

|

Join Date: Jul 2010

Location: McMurray,

PA

Cobra Make, Engine: Superformance #522

Posts: 528

|

|

Not Ranked

Not Ranked

Why the Air Gap on such a large displacement?

|

06-17-2014, 04:06 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

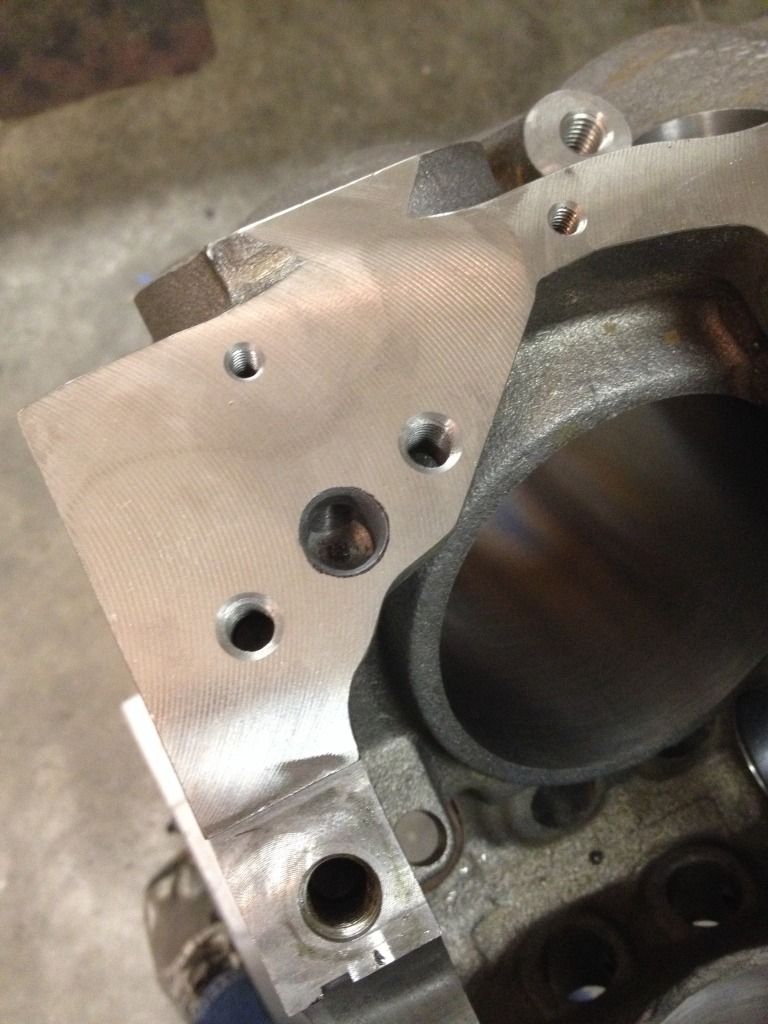

Picked up block yesterday and knocked in the cam bearings. Started a little prep work today.

Here's an area that needs to be addressed on every Dart block I've used:

The counterweight on the crank will inevitably rub one of the oil passages going to the #4 main bearing and sometimes on #2 and #3. I usually slather the whole area with a Sharpie marker and I get a good witness mark. Then comes the die grinder...

More to follow... |

06-19-2014, 02:45 PM

|

|

CC Member

|

|

|

Join Date: Aug 2007

Location: Carlsbad,

Ca

Cobra Make, Engine: SPF 2932 with 438 Lykins Motorsports engine. Previous owner of FFR 5452.

Posts: 2,616

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by blykins

Picked up block yesterday and knocked in the cam bearings. Started a little prep work today.

Here's an area that needs to be addressed on every Dart block I've used:

The counterweight on the crank will inevitably rub one of the oil passages going to the #4 main bearing and sometimes on #2 and #3. I usually slather the whole area with a Sharpie marker and I get a good witness mark. Then comes the die grinder...

More to follow... |

So that was the clanking noise I heard on my previous engine.

Eventually went away!

__________________

Jim

|

06-19-2014, 05:14 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Doesn't take much....hit the 3 center bulkheads with a die grinder...

Did a lot of checking...

Checked piston/cylinder clearance. Checked deck height on four corners.

Also did a little oil pump feed hole gasket matching...

Broke all the rods down from where I had checked rod bearing clearances, and I'm dropping the rotating assembly off tomorrow to be balanced. |

06-17-2014, 04:08 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

BTW, the bearings look like they've been through battle because they are mock-up bearings that I use for..............mock up....

|

06-19-2014, 09:26 AM

|

|

CC Member

|

|

|

Join Date: Jan 2008

Location: Nashville,

TN

Cobra Make, Engine: Backdraft, SBF 351w (463 CI)

Posts: 272

|

|

Not Ranked

Not Ranked

Brent what is the average runner flow on the Air Gap (Pre and post porting)?

|

06-19-2014, 09:48 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Average? I think somewhere around the 250 mark out of the box, and around 310-320 ported.

|

06-19-2014, 09:48 PM

|

|

CC Member

|

|

|

Join Date: Jan 2008

Location: Nashville,

TN

Cobra Make, Engine: Backdraft, SBF 351w (463 CI)

Posts: 272

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by blykins

Average? I think somewhere around the 250 mark out of the box, and around 310-320 ported.

|

Hum,,,,, I had always thought a victor Jr was the best option for a Big inch Windsor (Hyd street engine) but i can see with those flow numbers that I'm wrong. Thanks

MP |

06-20-2014, 04:23 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

It just all comes down to what you're doing and how much money you want to spend out of the gate. A Victor Jr. would have better flow numbers out of the box, untouched. I've used them out of the box, with exception of milling the flanges and have got 550 hp out of these bigger Windsors.

The Super Victor will flow out of the box what the ported Performer RPM Air Gap will with port work.

From what I've seen the Air Gap will help lower rpm numbers and will provide Victor Jr numbers up top. I would attribute that to intake runner length and maybe some wave harmonics.

|

06-20-2014, 05:59 AM

|

|

CC Member

|

|

|

Join Date: Aug 2007

Location: Carlsbad,

Ca

Cobra Make, Engine: SPF 2932 with 438 Lykins Motorsports engine. Previous owner of FFR 5452.

Posts: 2,616

|

|

Not Ranked

Not Ranked

Is the oil hole in the cam bearing in the correct location relative to the block?

__________________

Jim

|

06-20-2014, 06:04 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Yep.

These bearings are coated bearings from dart. They are grooved on the back and they have 3 holes on them. I make sure one feed hole is at 4:00 and let the other two fall at other clocked positions. Kind of a crazy bearing design and if you talk to some of the durabond guys, they will tell you that they are not sure why they did that.

|

07-01-2014, 10:49 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

I aim for .0028-.003 with 2.750" sized mains.

I'm at .002-.0022 with standard bearings. Easily fixed with a standard on one side and an X on the other side.

|

07-04-2014, 11:26 AM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

|

07-10-2014, 07:13 PM

|

|

CC Member

|

|

|

Join Date: Dec 2001

Location: Louisville,

KY

Cobra Make, Engine: I'm Cobra-less!

Posts: 9,417

|

|

Not Ranked

Not Ranked

Timing cover is on and fuel pump is on.

I have a tool that I use to center the timing cover. One end is for Windsors and Clevelands, the other end is for FE's. I used to try to align the timing cover by the balancer or the balancer spacer, but I had a couple of front seal failures by doing it that way. Normally, when you try to align with the balancer or spacer, you find yourself trying to make the flange of the timing cover flush with the pan rail of the block, and you'd be surprised at how many timing covers will not be flush when perfectly centered.

Anyway, I use the tool, bolt the cover up, then in the Windsor/Cleveland's case, pop the seal on with another tool.

Also got the head gaskets and heads bolted on. I torque them and then let them sit overnight (or at least several hours) then I go back and re-torque. You oughta try it sometime: torque the fastener, mark it, then back it off and re-torque. Due to fastener stretch and gasket loading, you will end up moving the fastener further to achieve the same torque spec.

I also test-fit the intake manifold. On a single plane, it's mucho easy to check port alignment. On most dual planes, it's a pain in the butt.

This is where a bore scope comes in handy.

I first check manifold fitment without a gasket. This lets me get a general idea of where I'm at, plus it lets me see how close the intake flange angle is against the head flange.

Sometimes the intake is perfectly aligned with no gasket, so that means it needs to have the flanges whacked off. In this case, it needed to be moved up, so I tried it with some gaskets. The picture above is with a .060" gasket. It's not bad, but could stand to be better. I tried it again with a .090" 1262R gasket and it was pretty much dead on, so that's what I'll use.

Pushrods and rocker arms came today. Delivering a 428CJ to Boss Cars in Gahanna, OH tomorrow, so I won't get much work done, but I plan to get a good chunk finished this weekend. |

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 12:11 PM.

Links monetized by VigLink

|