Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

November 2025

November 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

29 |

| 30 |

|

|

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

10-11-2012, 06:08 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,533

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by tboneheller

Grease on the drill bit will catch a lot of the shavings. This works good with a tap as well.

|

I haven't had time to measure the fitting yet - anyone happen to know what size hole and thread count for a tap is needed? Appears to be the same as for the heater hose nipples. I'm wondering if it's a pipe thread tapping also (NPT?). I will probably have to look around in Sears for one of those. |

10-11-2012, 06:18 AM

|

|

CC Member

|

|

|

Join Date: Dec 2011

Location: West Chester,

PA

Cobra Make, Engine: ERA #795 427 S/C completed Jan. '14 - '68 FE 427 side oiler

Posts: 1,059

|

|

Not Ranked

Not Ranked

Hi Dan,

I'd suggest speaking with Doug at ERA if you haven't already. He could likely answer all your questions, including the type and size of the thread you'll need.

Regards,

Kevin

__________________

"Anyone who drives faster than you is a maniac and anyone who drives slower than you is an idiot" - George Carlin

|

10-11-2012, 07:03 AM

|

|

CC Member

|

|

|

Join Date: Jan 2008

Location: Williamsport,

PA

Cobra Make, Engine: Kellison Stallion 468 FE

Posts: 2,703

|

|

Not Ranked

Not Ranked

using Patrick's pic as a guide i use the port closest to the distributor. that port will pick up the temp from crossover between the two heads.

and yes the thread is NPT, i think if i remember its 1/4 NPT if you buy a tap be sure its not just a carbon steel tap or you may break it off. make sure the tap package or the seller shows it to be HSS high speed steel.

use tapping fluid for lubrication or liquid soap if none is available. if you have any tube lying around use it as a sleeve for the tap to insure its going in straight...

__________________

Fred B

Last edited by FWB; 10-11-2012 at 07:11 AM..

|

10-11-2012, 09:08 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

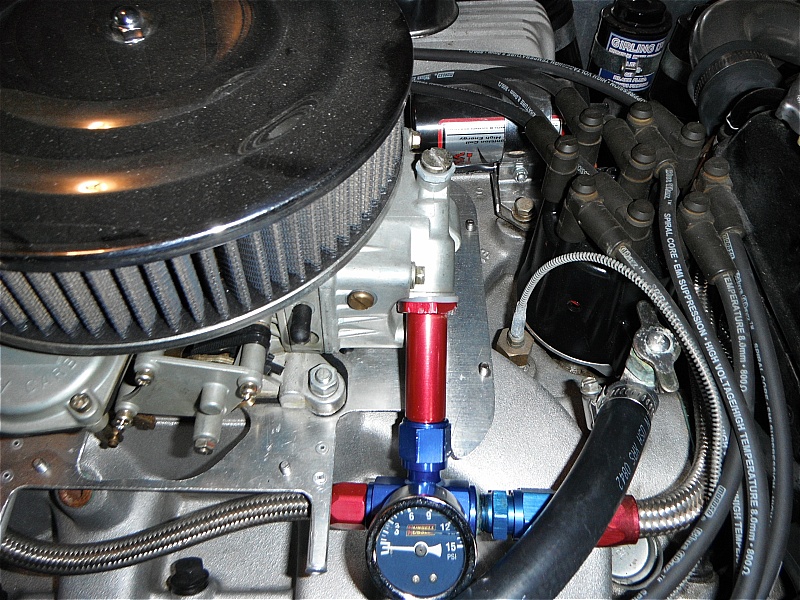

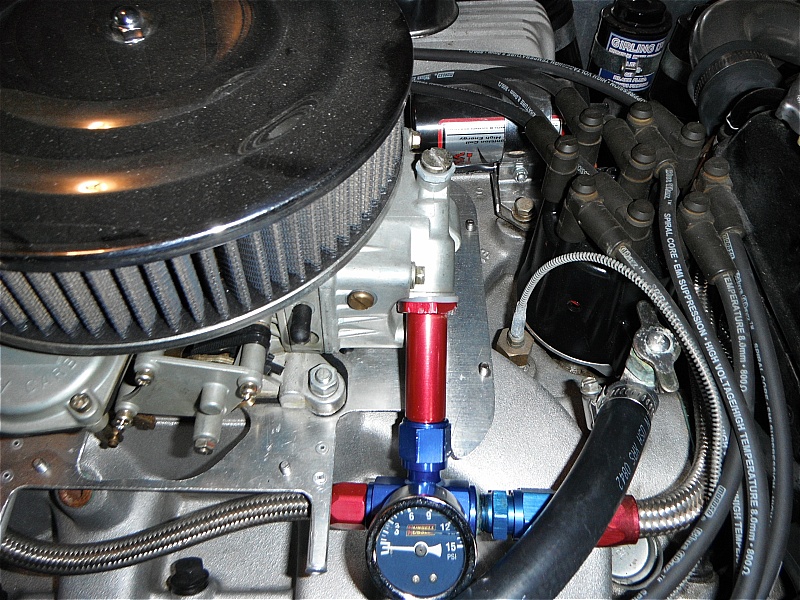

What should govern what port you choose for what is whether or not it will fit along with your fat little fingers. I'm assuming you're going to put a little shut off valve in the manifold -- they're only a couple of bucks from Summit -- but you have to make sure that you can reach your hand in there and that the handle of the valve doesn't hit something (like your front carb, or in my case a Turkey Pan, which is removed for this shot). Here's the shot of mine and you can see why it is why it is:

Last edited by patrickt; 11-03-2016 at 10:38 AM..

|

10-11-2012, 09:15 AM

|

|

CC Member

|

|

|

Join Date: Jan 2008

Location: Williamsport,

PA

Cobra Make, Engine: Kellison Stallion 468 FE

Posts: 2,703

|

|

Not Ranked

Not Ranked

OMG no...no...there's dust on Pat's aircleaner.

your slipping,

__________________

Fred B

|

10-11-2012, 10:16 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,533

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

What should govern what port you choose for what is whether or not it will fit along with your fat little fingers. I'm assuming you're going to put a little shut off valve in the manifold -- they're only a couple of bucks from Summit -- but you have to make sure that you can reach your hand in there and that the handle of the valve doesn't hit something (like your front carb, or in my case a Turkey Pan, which is removed for this shot). Here's the shot of mine and you can see why it is why it is:

|

I will be plumbed the same way as I already have my heater hose nipple/shutoff valve in place and my hoses run.

Patrick - how did ERA run the tubes on your motor for the oil temp sensor and the oil pressure line? Over the top of the engine and down to the oil filter housing and pan - or down at the firewall and along the lower side of the block?

Thanks |

10-11-2012, 10:48 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by DanEC

Patrick - how did ERA run the tubes on your motor for the oil temp sensor and the oil pressure line? Over the top of the engine and down to the oil filter housing and pan - or down at the firewall and along the lower side of the block? |

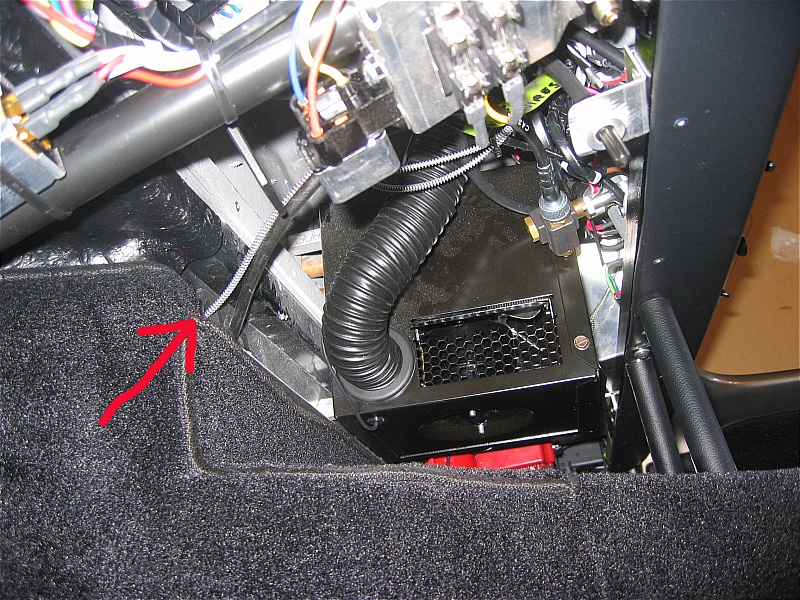

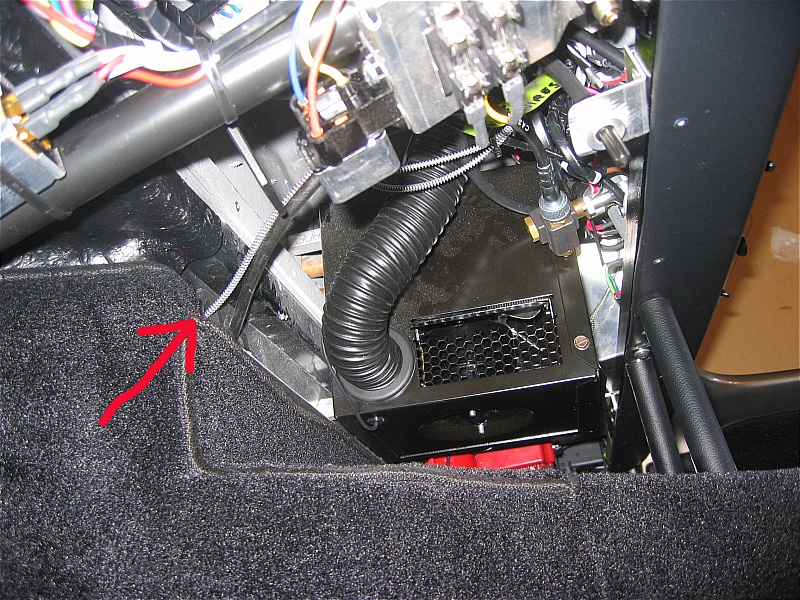

The oil temperature sender is located on the driver side rear of the Canton pan. The sending tube goes straight up and through a grommet located below the fuse boxes, There are two grommets there, actually, and the passenger side grommet is for the speedo cable and the driver side grommet is for the oil temperature sender. You can't see it in the second pic, but the arrow is pointing to it. The oil pressure tube runs from the filter housing directly over to the fender and up and under the fender to a hidden grommet along the firewall. You can see it in the pic and the other red arrow is pointing to it.

Last edited by patrickt; 11-03-2016 at 10:38 AM..

|

10-11-2012, 11:05 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Oil temperature tube as viewed from inside the car.

Last edited by patrickt; 11-03-2016 at 10:38 AM..

|

10-11-2012, 11:42 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

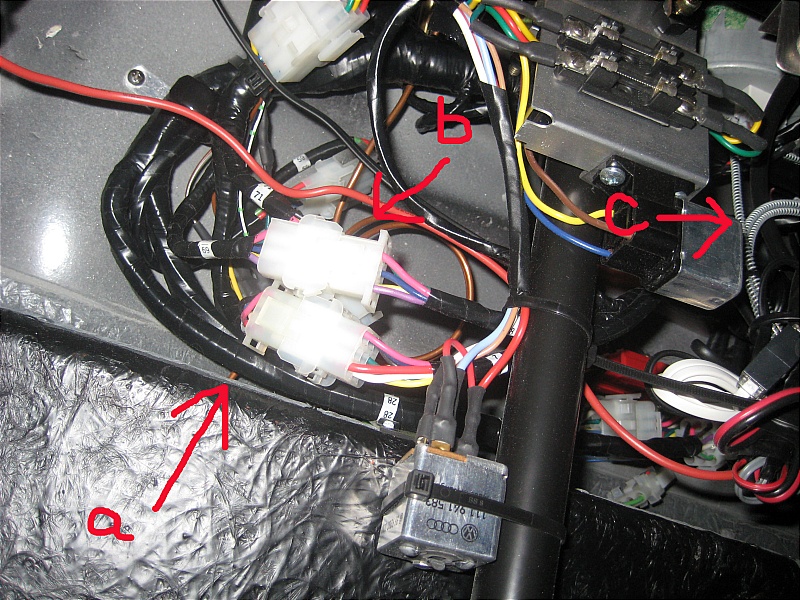

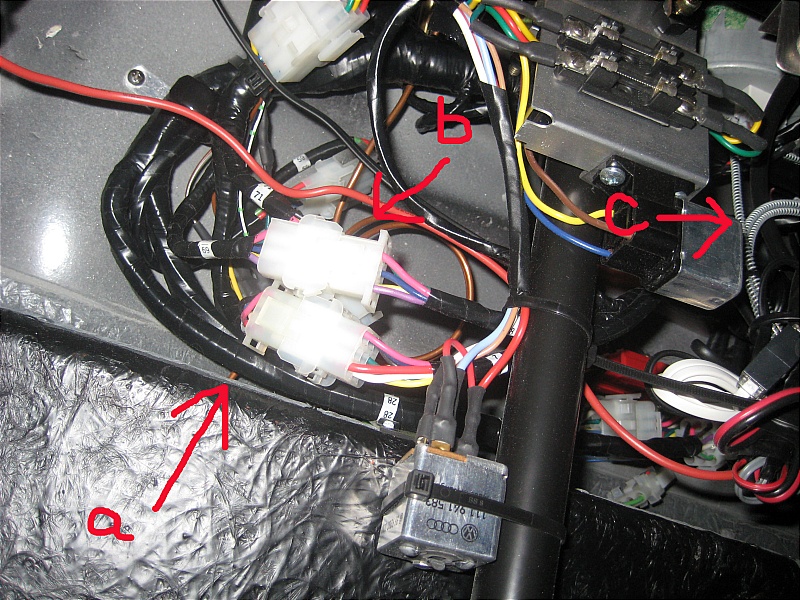

This is a good shot because it illustrates three points: A is the entry point of the oil pressure line, through the hidden grommet on the firewall, as viewed from inside the car looking up. B shows the oil pressure line loops that help to avoid vibration leaks, and C shows the loops for the excess capillary tube. Someone around here, maybe it was Chas, tried cutting and splicing the capillary tube instead of looping it. (No, it wasn't Chas  )

Last edited by patrickt; 11-03-2016 at 10:39 AM..

Reason: typo

|

10-11-2012, 11:52 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,533

|

|

Not Ranked

Not Ranked

OK - thanks for the information. I think you have the SC dash - is your oil pressure gage in the center or over by the steering wheel? I have a steet dash and that seems like a long way around to hit the gage in the center. But, either way I think running them down low along the side of the block will work best.

Thanks again

Ahh - more pictures. Should be self explanatory now.

Last edited by DanEC; 10-11-2012 at 11:54 AM..

Reason: More pictures

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 08:59 AM.

|

)

)

Hybrid Mode

Hybrid Mode