Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

February 2026

February 2026

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

|

CC Advertisers

CC Advertisers

|

|

06-22-2009, 03:50 PM

|

|

CC Member

|

|

|

Join Date: Dec 2000

Location: Livermore,

CA

Cobra Make, Engine: ERA #629, BBM Side Oiler Block, 482ci, Richmond 5 speed

Posts: 853

|

|

Not Ranked

Not Ranked

Priobe,

I'm using the Precision high volume oil pump in my 428. When I first put the motor together, I installed the spring spacer to give me the higher oil pressure. For my motor, that was a big mistake. When the oil was cold, I'd peg the meter at at well over 100 PSI with the RPMs above 3000 or so. Even once the oil got hot, I was looking at pressures of about 90 PSI. I tried running thinner 5W-30 oil and that made only a marginal difference. I finally pulled the pan and removed the spring spacer. With warm oil I now have about 65 PSI above 3000 RPMs and about 35 at idle.

I wouldn't use the spring spacer unless you have exceptionally large bearing clearances.

Chris |

-

Advertising

06-23-2009, 06:37 AM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,383

|

|

Not Ranked

Not Ranked

cj428cj,

Well, I really did not want to post my readings on my oil pressure because of the debate that it would stir up. I have search online as well as books and I have found just as many people say that the pressures are normal as those that say they are too low.

First of all let me provide as much information as possible.

Block is mechanical, so I only have 1 plug behind the timing chain cover related to oil. This is in place because because I get 80 psi when cold.

Rods are .002 and mains are .0025. I dont believe that these are large clearances.

I am running a pressure relief valve, which is installed correctly that has a 150 psi spring in the back of the block, according to Dove.

The heads have .060 restrictors in the head.

The cam bearings are lined up with the hole.

Oil adaptor does not have the extra hole where it mounts to.

I use to have 2 oil filters and replaced it with 1 filter (Motorcraft ) no difference.

The pump is a Melling HV 57 with a high pressure spring - without shim

The motor has 250 miles and no noises or junk in the filter.

I have noticed that my oil pressure when cold goes to 80 psi after it warms up it drops to 10 psi @ 180-190 water temp. As soon I hit the gas the oil presure shoots up to 40 psi then at cruse speed 2500 rpm oil pressure is 50 - 60 psi.

I am not sure if I install the shim if it will bump the pressure at idle up alittle.

I am running 15w 40 Rotella oil.

And I do not have a oil cooler hooked up.

Your thoughts

|

06-24-2009, 09:17 AM

|

|

CC Member

|

|

|

Join Date: Jul 2008

Location: Driftwood,

TX

Cobra Make, Engine: Contemporary Cobra, 427 side oiler

Posts: 1,850

|

|

Not Ranked

Not Ranked

I found Doug at Precision Pumps to be very knowleadgeable about all this. If your concern is the 10 psi at idle, why don't you give him a call and chat with him? (559)325-3553 or pumpbldr@comcast.net. |

06-24-2009, 09:24 AM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,383

|

|

Not Ranked

Not Ranked

elmariachi,

Thank you for the suggestion. I spoke to Doug and he said he has heard of plenty of motors run that type of oil pressure. ?He said it was perfectly normal to get that pressure.

I know someone of you dont agree but whats done is done.

I guess I will put this behind me and enjoy my ride. If something happens then I guess I will have to deal with it.

As a last precaution, I will cut open my filter one more time and see if there is any junk in the filter.

Other than that

Happy motoring   |

06-24-2009, 10:09 AM

|

|

CC Member

|

|

|

Join Date: Jul 2008

Location: Driftwood,

TX

Cobra Make, Engine: Contemporary Cobra, 427 side oiler

Posts: 1,850

|

|

Not Ranked

Not Ranked

I know how you feel. I have waited my whole life to own a side oiler-powered Cobra and the last thing I want is to grenade an engine or suffer from staring at gauges all the time, wondering what's going to happen next.

Good luck with it.

Jim

|

06-24-2009, 10:46 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: E BRUNSWICK N.J. USA,

Posts: 3,841

|

|

Not Ranked

Not Ranked

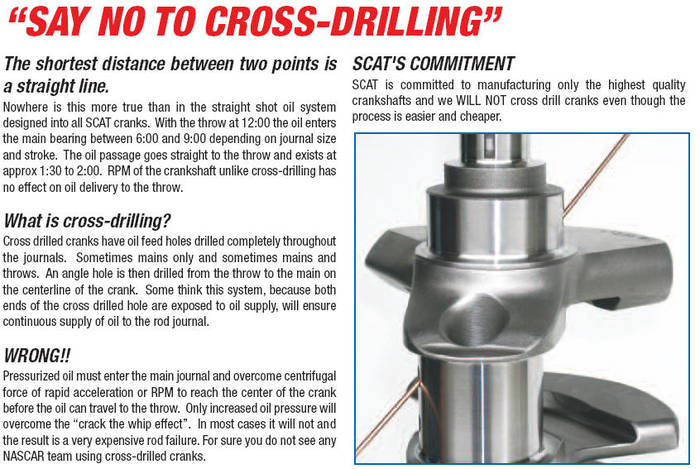

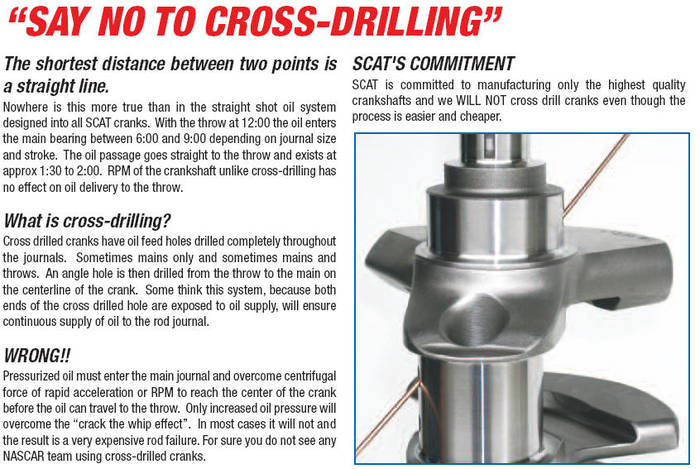

brain dead@#$%%!@#$$%

brain dead@#$%%!@#$$%

priobe Phil The reason you have low idle oil pressure is the crankshaft. If it is the nascar steel shaft, IT"S CROSSED DRILLED. It uses twice the normal oil and cuts the pressure twice as fast. Sorry for being brain dead. The other thing is that you may want to run a HV oil pump and use your spring kit for 80 psi. I found the blueprinting for this motor. .002" on the mains and .0025" on the rods. this is with your rods. This also includes the correct rod bearings that are .080" wider. This is from a 1967 manual on this motor. Caution note was not to let motor idle for any period of time. What ever that means. I would have to look for specs on the GPM for each oil pump but off the top of my head there is a 30% supply differents between the too. Maybe a HV pump is a better deal with more supply to offer. It may also give you another 5-10psi at idle. This may help extend the motor life.  Sorry for the brain fart.    Rick L. |

06-24-2009, 10:59 AM

|

|

CC Member

|

|

|

Join Date: Mar 2004

Location: miami,

FL

Cobra Make, Engine: E-M Cobra Ford FE 427 w/ Webers 48 IDA

Posts: 1,383

|

|

Not Ranked

Not Ranked

elmariachi,

I agree with you 100%. It get s to the point that you just have to feel confident with what you or your builder has decided for the build and run with it.

Rick,

When speaking to Doug @ PO he said the spring kit would not make a difference at idle. I have also heard that these motors should not remain idling for too long also.

I am running the HV 57 which is a high volume oil pump. I was thinking alot of comments are said about you should have this much psi but nothing about volume. With increased psi you will lower your volume and vice versa.

My clearances are as you suggested above and the crossed drilled on the crank I have heard does not make a difference with oil psi.

Have you noticed by changing the spring or adding a shim that the pressure increases at idle?

I guess I will look more into the cross drilling of the crank.

|

06-24-2009, 12:38 PM

|

|

CC Member

|

|

|

Join Date: Jul 2008

Location: Driftwood,

TX

Cobra Make, Engine: Contemporary Cobra, 427 side oiler

Posts: 1,850

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by RICK LAKE

priobe Phil The reason you have low idle oil pressure is the crankshaft. If it is the nascar steel shaft, IT"S CROSSED DRILLED. It uses twice the normal oil and cuts the pressure twice as fast. Rick L.

|

So Rick, is it your opinion that his idle oil pressure is normal for an engine with a cross-drilled crank? |

06-24-2009, 02:08 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

C'mon Rick, I've got documents in the manilla envelope...

C'mon Rick, I've got documents in the manilla envelope...

Quote:

Originally Posted by elmariachi

So Rick, is it your opinion that his idle oil pressure is normal for an engine with a cross-drilled crank?

|

Uhhh, Rick... isn't it true that the oil pressure sending unit for oil pressure lights was pre-set to 7 psi at the factory?  And And, the owner's manual assuaged the driver by telling them that it was perfectly normal for the light to flicker when coming to a stop? (N.B. -- Unless you admit to both of these, you'll just force me to post the excerpts from the service and owner's manuals.  ) |

06-24-2009, 03:41 PM

|

|

CC Member

|

|

|

Join Date: Jul 2008

Location: Driftwood,

TX

Cobra Make, Engine: Contemporary Cobra, 427 side oiler

Posts: 1,850

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by patrickt

(N.B. -- Unless you admit to both of these, you'll just force me to post the excerpts from the service and owner's manuals.  ) |

Man, you guys are brutal.

I guess this is the first I have heard of low idle oil pressure being directly related to the cross-drilled cranks. Not disputing, just wanting to learn. |

06-24-2009, 06:01 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: E BRUNSWICK N.J. USA,

Posts: 3,841

|

|

Not Ranked

Not Ranked

I am not an engineer or master engine builder

I am not an engineer or master engine builder

elmariachi Here is what I know from 1 motor that was built about 23 years ago. It was a dirttrack motor, SBC destroked to a 267 from 283. 9,400 rpms it would spin. This motor had a Hank the crank, chrome harded surface crank in it. It was cross drill and ran for a full season without any bottom end failure. The oil pressure was 12 -15 psi at 1,000 rpms and go to 65-70 psi on the track. Left hand turn all the time. The rods where Carillios. Mike said that if the oil pressure dropped to 8-10 psi the motor needed new bearings. Mike ran the NE coast dirt track like flemington, which is long gone. I did see the bearings at the end of the season with about 15 events with 3 rounds at each show. The coating was gone and you could see bronze coloring of the bearing. He said that this was the hardest bearings he could get and this is why the bottom end lasted so long. Every body had tricks back then and still do. As far as Priobe motor, he is not running the extra wide bearings. I have heard that they are not needed on a street motor, Again a GREY AREA. .080" is alot in todays world BUT may be not 40 years ago. The only reason I can fine for wider bearings is Load surface and the nascar rods could weight up to 1000 grams each. Crossdrilling the crank gave two locations to help keep the rod bearing floating on the oil film. They also used straight oil in the 40-60 range wieght. That is thick. Today we run 0 wieght. 1 of the builders on this forum and others said that the Scat kits redid the oiling of the crank shaft. The oil is pushed in the rod bearings about 30-50 degrees after or before TDC. I forgot which it was. This pressure helps keep the bearing off the crankshaft on the compression cycle and even more important the exhaust cycle. Oil act as a cushion. Kieth Craft, Kuntz, and a couple of other pro racers would be the ones to ask about this. IMO and this not being a SBC motor, 10-15 psi would have me nervious. As long as the rocker arms are not maken any noise, I GUESS it's OK. I wouldn't let this motor idle for any length of time.

patrickt Patty my boy, I believe it was from 8-15 psi depending on motor and automobile.  If the car was idling at 600 rpm with AC running and trans in gear, the light might flicker on a 100 degree day in traffic. Again in the old days running heavier oil with cligging elements in the oil or a bottle of Richard Petty's little blue bottle.  No Pat I am not talking about sex pills in liquid forum.   STP. I do know that GM motors that had the lights come on at idle, 90% of the time came with a rod knock on a cold startup. The end was near.  Some motor lasted for years even with the knocking. My grandmother had a 57 4 door with a 6 cylinder and iron power glide. In the summer in traffic the oil light would come on and the motor would start clicking. Rockers where not getting any oil. This motor lasted the life of the car. In the old days if was pretty hard to kill a motor unless you never changed the oil.Your turn, POST AWAY!!!!!!      Rick L

Last edited by RICK LAKE; 06-24-2009 at 06:03 PM..

|

06-24-2009, 06:28 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by RICK LAKE

|

Hmmm, I remember a better one than this.

|

06-24-2009, 07:17 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by RICK LAKE

1 of the builders on this forum and others said that the Scat kits redid the oiling of the crank shaft. The oil is pushed in the rod bearings about 30-50 degrees after or before TDC. I forgot which it was. This pressure helps keep the bearing off the crankshaft on the compression cycle and even more important the exhaust cycle.

|

.................. |

06-27-2009, 10:57 AM

|

|

CC Member

|

|

|

Join Date: Mar 1999

Location: TACOMA,

WA

Cobra Make, Engine: Everett Morrision FE 427 so 2-4s

Posts: 2,025

|

|

Not Ranked

Not Ranked

I had a cam go flat on two lobes. When I rebuilt my engine I replaced the oil pump with a Mellimg HV pump from Perscision Oil Pumps. When I called, I was asked if I wanted the truck version. I asked what the differences were. The truck version has a 5/16" hex rather than the 1/4 " hex of the car. I also ordered a drive shaft from Persision / 5/16" hex most of the length and a 1/4" hex end for distributor. I asked why and was asked to inspect my distributor and oil pump sockets. Seems the oil pump socket is the first to show sign of the hex wearing and rounding out. Sure enough my distributor socket was just fine but the old pumps 1/4" hex socket appeard to be about to round out. I installed the shim to the releif spring and run about 75 psi most of the time. I was instructed to let the oil warm untill at least

140° is showing on the oil temp gauge before getting carried away with the throttle. I didn't once and sheard the 1/8" by 3/4" sprimg pin in the distributor gear. Its a built in weak point. When it shears, everything stops, no harm no foul . It takes about an hour to repair if it happens in your backyard. I did beef it up a little by ordering a true "roll pin" By MSD from Summit. If you do a search there are stories about foreign objects locking up the oil pumpand twisting the hex drive shaft and stories and pictuers of extreme pressures and high volume wearing out the teeth on the distributor and cam gears. The picture I remember, the distributor gear had the teeth worn down to virtual flaps and several teeth were allready chipped away.

Currently the wish list would to have a dual oil filters connected parrallel to increase volume and or decrease flow resistance . I have the dual filter unit but don't know where I'd mount it though.

__________________

Mike H

|

06-27-2009, 12:32 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jan 2004

Location: St. Louis,

Mo.

Cobra Make, Engine: 427 S.O. Dual Quad / Cobra undecided

Posts: 1,380

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Michael C Henry

I was instructed to let the oil warm untill at least 140° is showing on the oil temp gauge before getting carried away with the throttle.

|

Same point my dad shared with me when I was a little kid helping him work on his race car, "always wait until the oil temp gauge moves before driving" |

06-28-2009, 07:01 AM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: E BRUNSWICK N.J. USA,

Posts: 3,841

|

|

Not Ranked

Not Ranked

You would be better with a larger single filter

You would be better with a larger single filter

Michael C Henry Mike I have run dual filters and they are not worth it. We use them. You might want to look at getting larger lines, like#12 or #14 with hiflow connectors. Getting a large 2 quart single filter hiflow. This is what they use on medium size diesels motors. Winx or Mobil 1 sell this filter with a large inlet and outlet. It's either 13/16 or 7/8". For your application there will not be any restriction. I will look and see if I can find the numbers of these parts for you. I am going the same way with my next motor. Everything is larger inlets and out lets. Lines, connectors, cooler, and dry sump pump. Rick L.

|

07-14-2009, 07:46 AM

|

|

CC Member

|

|

|

Join Date: Jul 2009

Cobra Make, Engine:

Posts: 417

|

|

Not Ranked

Not Ranked

After some research into old FE articles, it seemed like 80 psi would be a good max to set the oil pump relief spring. I believe that old adage about 10 psi for every 1000 rpm relates to Chevs only.

Oh...before I go on, I should mention that I am a firm believer in that bearings need the same amount of oil pressure and flow to keep sufficent lubrication regardless of engine brand. The only reason a FE needs more than a Chev, is the longer, narrower (more restrictive) oil galleries. We may wind up with different rpessures at the gauge location, but the final pressure at the bearings should be the same. Just my opnion.

So.....I removed the oil pump relief press-in plug, removed the spring and tapped the oil pump housing with a 5/8-27 tap (not a common tap, but other threads could be used). I then threaded a piece of brass stock, and then made it into a cup shape with my metal lathe. Finally, on the flat side, I drilled two small "blind" holes so I could turn the cup with a snap-ring pliers.

Next, using 1/4" Al plate, I made two adapters for the oil pump. On the outlet plate, I installed a gauge, and then a valve.

I installed the spring and the plug, put on the plates, and cranked the oil pump with a 1/2 Hp electric drill. Once the oil was flowing and no air was left in the pump, I closed the valve to increase the pressure to max.

First attempt I couldn't get close. Tried a different spring. Now I was getting somewhere. Adjusted the oil pressure for about 83 psi max. The gauge was pulsing a lot, so I sort of went with an average figure.

I then staked the tope of the plug in two spots so it wouldn't turn during operation.

I was worried the drill wasn't powerful enough, or spinning fast enough to simulate the engine, but everything turned out fine. Cold idle start-up, I got 85 psi (which is also max for hot oil at higher rpms).

So....what this did for me, was allow me to adjust the oil pump wihtout having to keep installing and re-installing the pump. That's a pain as the oil-pan has to come off, new gaskets are required, and the car has to be jacked up and put on axle stands each time.

As an aside, let me go on a bit about Mallory distributors and HV pumps. It wasn’t very long after installing the Mallory, that my engine suddenly died while driving. The split pin holding the distributor gear to the shaft broke in 3 pieces. This was caused by fatigue….continued bending of the pin. Why? Because the Mallory gear is a sloppy fit to the Mallory shaft. A Ford typically had the gear pressed on the shaft and can be a pain to get the pin holes lined up. Not being sure if this was normal or not, I ordered a new shaft and gear through Summit. On backorder. So, like a dummy, I ordered a whole Mallory distributor, since it was in stock.

Subsequently, I contacted Mallory. They told me the pin usually breaks when using a HV oil pump, and of course, that’s what I was using.

I then modified both distributors. The original pin was 1/8” diameter. If memory serves me correctly, I re-drilled the hole through the gear and shaft with a #21 (or it may have been a #22) drill and pressed in a 5/32” split pin with another 3/32” pin “nested” inside it. Splits 180 Deg apart, up and down. So far, and 3000 miles later, the modified pin is holding up fine.

And then I spent the best money I ever spent. I purchased a Pertornix unit for the distributor....about $70. Acceleration was very clean after that.

|

07-14-2009, 12:04 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Concord Twp.,

OH

Cobra Make, Engine: Everett-Morrison 427SC 302 smallblock. 431 stroker in the works, tremec 3550

Posts: 200

|

|

Not Ranked

Not Ranked

I bought an "off the shelf" Melling HV pump for my 390 stroker before I found out about Precision. I would like to get the most out of this pump. What is entailed in "blueprinting" an oil pump?

|

07-14-2009, 12:20 PM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Tom Cimino

I bought an "off the shelf" Melling HV pump for my 390 stroker before I found out about Precision. I would like to get the most out of this pump. What is entailed in "blueprinting" an oil pump?

|

Blueprinted Melling Ford FE High Volume 1/4" Pump

SKU: M-57HV

MELLING HIGH-VOLUME BLUEPRINTED OIL PUMP.The pump is a brand new Melling M-57HV blueprinted by PRECISION OIL PUMPS. Fits all FE Ford 352-427 with the std 1/4" drive. Each pump is disassembled in groups of ten. All passages have casting flash removed, corners are radiused and blended by hand. Housings & Gears are Deburred by a Vibratory Polisher then cleaned. Gears are then sprayed with TECH-LINE moly-coating and oven curred. Three Critical Clearances are checked on reassembly;(1) Gear to Housing, (2) Mesh or Backlash, (3) Gear to Cover-Plate. With Ten gear sets to choose from , One pair with correct clearances will be installed. The relief- valve is De-burred with emmory cloth ,cleaned and is re-installed with the existing brown (60-65 psi.) spring and new hardware. Each cover plate is also Vibratory Polished, cleaned and fastened with safety-wired aircraft bolts. All pumps are bench tested. Buy with confidence.

PRICE: $89.95

http://stores.precisionoilpumps.com/...-FE/Detail.bok |

07-14-2009, 06:27 PM

|

|

CC Member

|

|

|

Join Date: Mar 1999

Location: TACOMA,

WA

Cobra Make, Engine: Everett Morrision FE 427 so 2-4s

Posts: 2,025

|

|

Not Ranked

Not Ranked

They also have a truck version that has a 5/16" hex and a special 5/16" at on end and 1/4" at the other end drive shaft. I had it pointed out to me that it's the internal hex at the pump that suffers and the 5/16 helps with that. High volum is one thing and high pressure is the other, The two combined creaet a load, that is carried by the distributor shaft and gear and the pin that connects that gear to the shaft. It usually has a 1/8" pin ,a built in weak spot ( that is a good thing) Any larger pin will weaken the shaft and that is the distributor a lttle more, and moves the weak point (like a fuze) somewhere else, likely more expensive to repair. I found that out once when I razed the throttle before the oil was warmed up and that pin sheared. The engine just died. It took about an hour to repair. I did find that I only had a spring pin and I did buy a true roll pin to replace it. 1/8" x 3/4" an improvement but you couldn't find any other point that would be as cheap or quick to repair as a safety.

Whe i installed the new pump I just took out that soft plug installed the single shimm they sent as an option with the pump, but I also had doubts about that soft plug and converted it to a screw in pipe plug . I played around using seceral different taps with the ends ground off to get the same depth as the original soft plug. It looked right and ended up working as planned .

__________________

Mike H

Last edited by Michael C Henry; 07-15-2009 at 01:22 PM..

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 01:24 AM.

|

Sorry for the brain fart.

Sorry for the brain fart.

Rick L.

Rick L.

And, the owner's manual assuaged the driver by telling them that it was perfectly normal for the light to flicker when coming to a stop? (N.B. -- Unless you admit to both of these, you'll just force me to post the excerpts from the service and owner's manuals.

And, the owner's manual assuaged the driver by telling them that it was perfectly normal for the light to flicker when coming to a stop? (N.B. -- Unless you admit to both of these, you'll just force me to post the excerpts from the service and owner's manuals. )

)

STP. I do know that GM motors that had the lights come on at idle, 90% of the time came with a rod knock on a cold startup. The end was near.

STP. I do know that GM motors that had the lights come on at idle, 90% of the time came with a rod knock on a cold startup. The end was near. Some motor lasted for years even with the knocking. My grandmother had a 57 4 door with a 6 cylinder and iron power glide. In the summer in traffic the oil light would come on and the motor would start clicking. Rockers where not getting any oil. This motor lasted the life of the car. In the old days if was pretty hard to kill a motor unless you never changed the oil.Your turn, POST AWAY!!!!!!

Some motor lasted for years even with the knocking. My grandmother had a 57 4 door with a 6 cylinder and iron power glide. In the summer in traffic the oil light would come on and the motor would start clicking. Rockers where not getting any oil. This motor lasted the life of the car. In the old days if was pretty hard to kill a motor unless you never changed the oil.Your turn, POST AWAY!!!!!!

..................

.................. Linear Mode

Linear Mode