Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

|

|

1 |

| 2 |

3 |

4 |

5 |

6 |

7 |

8 |

| 9 |

10 |

11 |

12 |

13 |

14 |

15 |

| 16 |

17 |

18 |

19 |

20 |

21 |

22 |

| 23 |

24 |

25 |

26 |

27 |

28 |

29 |

| 30 |

|

|

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

3Likes 3Likes

05-16-2006, 08:52 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: IGH, MN,

mn

Cobra Make, Engine: scratch build self design 4.6l DOHC

Posts: 769

|

|

Not Ranked

Not Ranked

Fasterpatricks Custom Cobra

Fasterpatricks Custom Cobra

Last edited by fasterpatrick; 11-26-2007 at 09:14 PM..

|

05-17-2006, 11:40 AM

|

|

CC Member

|

|

|

Join Date: Jun 1999

Location: Portsmouth,

OH

Cobra Make, Engine: Undecided, 289

Posts: 200

|

|

Not Ranked

Not Ranked

Very Nice!  I'm wondering what spindles you are using up front? I have looked through some of your older post, but didn't see anything mentioned.

Jay Little |

05-17-2006, 03:47 PM

|

|

CC Member

|

|

|

Join Date: Aug 2004

Location: Tarpon Springs,

fl

Cobra Make, Engine: scratch building

Posts: 182

|

|

Not Ranked

Not Ranked

Fasterpatricks Custom Cobra

Fasterpatricks Custom Cobra

And the fun begins...tank after tank of argon...and a lot of reading and figuring.....Keep us posted with your progress..

Al

|

05-17-2006, 04:26 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Aug 2004

Location: Near Phila. (Collegeville),

PA

Cobra Make, Engine: CSX2498 has been in our family garage since '68....Scratch built aluminum bodied 427SC Cobra, 427FE, CSX3000 chassis specs, 95% finished, only needs paint.

Posts: 642

|

|

Not Ranked

Not Ranked

have fun Pat.

have fun Pat.

keep posting photos & have fun, Karl

|

05-17-2006, 08:13 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: IGH, MN,

mn

Cobra Make, Engine: scratch build self design 4.6l DOHC

Posts: 769

|

|

Not Ranked

Not Ranked

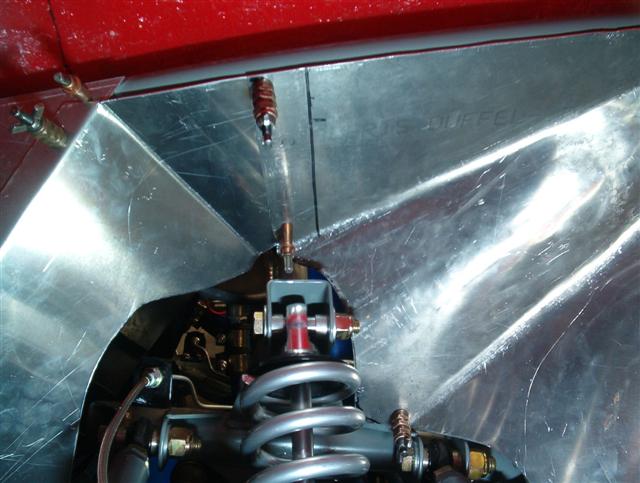

Front end parts are mustang II repo units with 11" rotors and manual rack, All from speedway motors. Got the whole works spindels, rotors, brakes, ball joints, steering rack, tierod ends, and assorted hardware for just over $700. Not a bad deal. It's pretty much what they use for modified stock circle track cars. Pat

|

05-30-2006, 08:38 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: IGH, MN,

mn

Cobra Make, Engine: scratch build self design 4.6l DOHC

Posts: 769

|

|

Not Ranked

Not Ranked

I have a question, which would be better solid aluminum steering rack bushings or should I use delerin(Poly). I will be machining the myself and stock for both. Just a survey question. Pat

|

06-05-2006, 09:29 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: IGH, MN,

mn

Cobra Make, Engine: scratch build self design 4.6l DOHC

Posts: 769

|

|

Not Ranked

Not Ranked

Hey everyone,

Look what happened, while everyones out driving around I'm in the shop working. Just a few photos of what I've been up to  Pat.

Last edited by fasterpatrick; 11-26-2007 at 09:14 PM..

|

06-05-2006, 11:21 PM

|

|

Banned

|

|

|

Join Date: Oct 2003

Location: Yorba Linda,

CA

Cobra Make, Engine: SPF w/392CI stroker

Posts: 3,293

|

|

Not Ranked

Not Ranked

You have skills.

-Dean |

12-23-2009, 12:10 PM

|

|

CC Member

|

|

|

Join Date: Jan 2007

Cobra Make, Engine:

Posts: 27

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by fasterpatrick

|

New question, what make is your rear end parts from??? |

01-03-2010, 09:33 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: IGH, MN,

mn

Cobra Make, Engine: scratch build self design 4.6l DOHC

Posts: 769

|

|

Not Ranked

Not Ranked

No more play time back to work

No more play time back to work

Well let's see, way to cold thank god for the heated shop. I've started back to work getting her ready for paint. The car is back on the chassis dolly, body is off the ceiling, and I have roughed in the fender wells on the front end of the car. These are times that I really do envy you guys that get to work with a kit. Having some of this metal work laid out for you must make this a little easier than trying to figure out, just how am I going to get this covered and how can I bend it this way. But I can get this stuff cleaned up and coated with the same stuff that the rest of the sheet metal is covered with.

Need to source the bulb-seal that I will need to go between the metal, frame, and body. With some luck I should be able to get the rest of the holes laid out that I need to cut into the body and start prepping it for undercoating. I can not believe how different this body is left to right. It's like they molded off of two different cars, guess that is what is meant by character.

Patrick |

01-03-2010, 09:48 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: Portland,

OR

Cobra Make, Engine: ERA FIA, 1964 289->Webers

Posts: 3,689

|

|

Not Ranked

Not Ranked

Kit's are pretty easy, in comparison, but bragging rights are something to cherish! Nice work! Keep the pics comin'!

__________________

ERA FIA 2088

|

03-06-2010, 07:47 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: IGH, MN,

mn

Cobra Make, Engine: scratch build self design 4.6l DOHC

Posts: 769

|

|

Not Ranked

Not Ranked

Wow two months with out an update

Wow two months with out an update

Okay guys, here it goes I have the rest of the missing sheet metal formed and coated. Now I cutout some of the holes in the body and found that it had been made very thin I believe this was because of all the extra glass work that would have needed to be done to bond the tub interior that the body kit came with. So I went back to the glass and resin store and picked up another 5gal and mat. So when the temps get back up so I can work with the shop open, I will make the body a bit thicker. For now I will continue to take care of small stuff. This unfortunate setback will delay the paint work which I was hoping to have done late spring.

More bad I came down with Shingles (Chicken Pox Revenge) three weeks ago, I would not wish this on anyone ( Okay maybe one or two people), so working out in the shop has been hit and miss.

I have made some small steps in the right direction. I have made myself a set of louvers for my car, before you all get testy about how they look they will be painted body color like "The Real Ones"

So everyone I'm not dead and I'm still plugging away until later,

Patrick |

06-09-2006, 07:09 AM

|

|

CC Member

|

|

|

Join Date: Apr 2004

Cobra Make, Engine: Scratch Build

Posts: 15

|

|

Not Ranked

Not Ranked

Awesome, Patrick, now I really want to get moving. I love your table, and wish I saw it sooner. I am almost done with mine. It is made of 7 nine foot 6 inch I-beams. It is too much table for my single bay garage.

I will try to finish it this weekend and make my first cut on the 4 inch tubes.

Thanks for the inspiration.

Iggy

|

06-09-2006, 09:23 AM

|

|

CC Member

|

|

|

Join Date: Apr 2004

Cobra Make, Engine: Scratch Build

Posts: 15

|

|

Not Ranked

Not Ranked

Patrick, this may only add weight, but do you think that it would help to drill out a hole in the front pumkin cross piece where the bolts go and weld in a section of pipe. The pipe would be flush top and bottom, also it would be welded top and bottom. So the cross piece would hold it steady, but never see compression. The bolts would just fit in the pipe. Just thinking that now you could tighten the pumpkin untill the bolts break without any stress on the parts.

I do see that the cross piece is so thick that this might be overkill.

Iggy

|

06-09-2006, 08:47 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: IGH, MN,

mn

Cobra Make, Engine: scratch build self design 4.6l DOHC

Posts: 769

|

|

Not Ranked

Not Ranked

Iggy,

I have done that many times in the past but with lighter stock. this crosmember is 3/16ths thick so yes it would be overkill. Was thinking about making the bottom hole large enough to tuck the bolt up inside the crossmember. That would make for a much cleaner look. Pat

|

06-25-2006, 10:51 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: IGH, MN,

mn

Cobra Make, Engine: scratch build self design 4.6l DOHC

Posts: 769

|

|

Not Ranked

Not Ranked

rear suspension drawings

rear suspension drawings

Hey guys,

Well I'm back, took the family to see dead presidents carved in stone. Black hills camping vacation, long drive but worth it, good time. Been getting more parts together and lots of cad time.

PLease tell me what you think of this for rear suspension layout nothing is set in stone yet. Will work in shock mounts when the shocks arive so I can get them drawn in the computer.  Pat |

06-26-2006, 10:10 PM

|

|

CC Member

|

|

|

Join Date: Jun 2006

Cobra Make, Engine:

Posts: 92

|

|

Not Ranked

Not Ranked

Patrick

Since you are still in the design stage you might look at the rear cover from an 8.8 Explorer, I like the mounting much better. I can get them for anyone interested for about $35 to $40. I believe with a load your arms would bend at the curve. I'm going to adapt the Locost Roarty plans for the 8.8 IRS. I know it is a Lotus 7 type but the general Idea would be the same. http://locost7.info/files/suspension...RSAssembly.pdf

|

06-27-2006, 10:57 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Cobra Make, Engine: scratch built aluminum chassis/bb

Posts: 6

|

|

Not Ranked

Not Ranked

Hey Pat,just a quick observation on your great work. I usually wait untill last to permanently mount the rack, this saves lots of time when sorting out any bump-steer.

|

06-28-2006, 06:08 AM

|

|

CC Member

|

|

|

Join Date: Apr 2004

Cobra Make, Engine: Scratch Build

Posts: 15

|

|

Not Ranked

Not Ranked

Pat it looks good. To Hesss'es point, you could diagonal the lower back arm (vs curve). The upper arm on many (Jag, FFR) is a single arm. The FFR uses an angled lower rear arm. The Heim joint hits at the same angle. Also the Lower rear mount is set 3 degrees lower than the front. I am told that both of these add anti-squat. I think that the angle binds the joints under power and tends to add anti-squat and toe-in (a desirable thing). I do not remember how the original was setup (I don't think it had the 3 degree down angle), but will look tonight. I also have a book somewhere that gives some guidance I’ll check this out. I also have seen where people use spherical bearings vs bushings as they may move more than the arms flexing.

Iggy

|

06-28-2006, 01:44 PM

|

|

CC Member

|

|

|

Join Date: Jun 2006

Cobra Make, Engine:

Posts: 92

|

|

Not Ranked

Not Ranked

FWIW I have been researching how to setup the IRS. I plan on using Rorty as general directions. I plan on using Stock Car Products links which are DOM and threaded for 3/4 rod ends. I like and will probably use Rock Krawler rod ends which have a 14 mm trunion bolt but they have a 10mm sleeve for them.

$30.00 Per Assembly for 3/4 Shank

+/- 20 degrees

60,000 Pound Radial Load Capacity

8,800 Pound Axial Load Capacity

Rebuild Kits $5.00 (New Poly Races)

Fits Clevis widths of 2.375"

14 mm Bore

I also believe I have found a cheap way to put spherical bearings in the spindle. Currie makes a johnnie joint which is a sleeve that looks like it would be a direct fit into the spindle.

2" Johnny Joint w/ Greaseable bolt

2 x 1.5 shell

2 trunion

CE-9112 Our Price: $37.95

Description: For fabricators and suspension system builders. Currie's Johnny Joints offer 30 degrees of unrestricted movement in any direction as compared to 22 degrees on a common heim joint. The bushings in the Johnny Joint rod ends are made with a high-density, "tough 88" urethane that encases the inner ball. It is a very durable material, and is impervious to weather. The special ball is heat-treated steel for extra strength, and is cross-drilled for thru-bolt lubrication. The outer shell is .180" DOM tubing, and the retaining washers are heat-treated steel. This 2" joint also includes a 7/16" greasable thru-bolt.

Unit of Measure: Each

http://www.currieenterprises.com/ces...nnyjoints.aspx

Last edited by hssss; 07-05-2006 at 12:58 AM..

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 02:44 AM.

Links monetized by VigLink

|