Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

| 29 |

30 |

31 |

|

|

|

|

|

CC Advertisers

CC Advertisers

|

|

11-01-2006, 09:55 AM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

How well does it steer with the spindles turned around to make it rear steer in the 32?

With coil overs that short and at that much angle does you have to use higher rate springs?

The units I've worked on we use the longer coilover and the mounting angle the Corvette used.Of course the upper mounts then become critical and bracing takes some imagination!

Jerry

|

11-01-2006, 10:39 AM

|

|

CC Member

|

|

|

Join Date: Dec 2003

Location: Gurnee,

IL

Cobra Make, Engine: Kirkham #259

Posts: 1,396

|

|

Not Ranked

Not Ranked

The better question is what is your Scrub Radius and how much Ackerman do you have.....

In the photo's you have a lot of Scrub...... and Ackerman seem to be going straight back...... not good.

Morris

__________________

Morris

|

11-03-2006, 02:45 AM

|

|

CC Member

|

|

|

Join Date: Oct 2006

Cobra Make, Engine:

Posts: 47

|

|

Not Ranked

Not Ranked

Jerry, the 32’s won’t handle as good as a front steer rack because of the added stress placed on the rack when its behind the knuckles. With the cobra we WILL run the up front power rack off the corvette and with the split in the upper a arm you don’t see in the C4’s. The 32’s you don’t have that option because of the placement of the radiator too the center of the front wheels. The weight and size of the roadster played a large role in the design of the frame. This car will weigh 1800-2000 Lb when finished, so a longer travel was not necessary, also remember this car will have no finders so the look was very critical to make it feel right and not ugly. The nice thing abut the corvettes is that all of the pinion angles, and spindle alignment is made in the upper A arm on the C4’s. With the C5 the front right knuckle and the rear left knuckle have the same part number, a dead give away, and all of the adjustment is taken care of by eccentric bolts on the lower A arms making it easer to convert to coil over shocks.

Morris, Wow dude, I saw your cobra in your gallery, I guess your serious about racing and its even more obvious by the question you asked. I just going to point this out we were building the 32’s for street use primarily, plus this chassis is just going back together so there are a lot of things that have yet to be adjusted before it goes on the road, mainly a trip to Manny’s Chassis shop up in Austin for tuning and alignment.

The C5 Cobra we are using the stock Corvette angles for now to get on the track and see what needs more or less adjustment and where.

To define for the people who don’t know what we are talking about. Unless my dyslexia is kicking in again this is what that all means right.

Scrub Radius - The distance between the extended centerline of the steering axis and the centerline of the tire where the tread contacts the road.

Now in English, Look at the front suspension in you head straight on from the front of the car and draw an imaginary line through the two ball joints where they pivot. Continue that line all the way through the tire to where it touches the ground. Ideally if the car is running in a straight line this line will place the majority of the weight in the center of the tire so you can have the most effective foot print when driving. That’s why all of the current Sports Cars have deep rims.

I’m suppressed you didn’t ask how much bump steer adjustment it takes to keep it on the ground in a serious turn but I’m sure it was on the way next.

The Ackerman Principal - The creation of toe-out when turning to minimize tire wear and to allow for better traction when turning. To create the proper geometry, the steering arms are angled to turn the inside wheel at a sharper angle than the outside wheel. This allows the inside wheel to follow a smaller radius circle than the outside wheel and there for allowing tighter turning radius. Once again, street car, the closest adjustment to reduce ware on the tires and still drive handle.

Will be back in a minute with some photos of up graded brakes it’s time for more candy on the frame.

|

11-03-2006, 03:31 AM

|

|

CC Member

|

|

|

Join Date: Oct 2006

Cobra Make, Engine:

Posts: 47

|

|

Not Ranked

Not Ranked

Sorry about that, I’m painting right now, Dads birthday is on the 7th and I wanted for him to be able do birthday donuts in his own roadster. For the last few years we almost get one finished to keep but, they either it makes it to a rolling chassis stage or just barely running then we have had to sell it. I count 5 times in the last 2 years so this year I was hoping to be a little different and give dad a nice birthday present for his 60th. (He’s old)

We have been working on this and our “paying jobs” plus we are waiting on the radiator, fuel cell, new oil pan, coil over shocks, and the torque tube to make there way to the shop and then we will really make some progress on the cobra.

And I thought this was funny a gentleman from the Round Rock Cobra Club saw the tail end of our cobra in the door and stopped to poke in and see what was going on. Turns out they do some serious racing, and he was familiar with the C5-C6 corvettes. So Jim looks over with this smug little grin on his face and asks “So when we get this running do you guys want to race?” the other guy just looked back at that transaxle and shook his head and said “I don’t think that would be fair.”

So here are some of the up grades and why I want to sell this one off and find a New Z06 the brakes in the photo from smallest to largest, C5 (97-04) stock front brake 2 pistons, C6 (05-06) Stock front brake as well as the C6 Z06 Rear brake 4 pistons and 4 separate brake pads. Last is the factory brake for the C6 Z06 front 6 piston and they all are interchangeable. This will make slowing down a piece of cake the only thing I would be worried about is some one who doesn’t know how to drive just locking up the brakes and loosing it.

And if any of my other info is wrong please correct me I have confused stuff before and the fact it’s 4:30 A.M. and i woke up at 10 AM. yesterday don’t help

Russell

|

11-05-2006, 09:16 AM

|

|

Evryday is a roadstr day

|

|

|

Join Date: Jan 2004

Location: North Jakarta, Indonesia,

Oh

Cobra Make, Engine: RHD Hurricane street roadster HM1081 aging nicely in the garage

Posts: 5,725

|

|

Not Ranked

Not Ranked

Of all the threads I've read, this one is right up there for the top award. Keep up the great photos, info and banter. I'm really enjoying it. Can't wait to see the finished product.

|

11-05-2006, 03:11 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gore. New Zealand.,

SI

Cobra Make, Engine: DIY Coupe, F/T ,MkIV.

Posts: 808

|

|

Not Ranked

Not Ranked

Russel,

With your front uprights reversed like that you will have a lot of reverse ackerman,( Toe in on turns ), If you want see how bad it is, apply left or right lock, throw a few sheets of newspaper on the floor and roll the front tyres over them with lock applied. If its bad it will shred the paper, if its good it wont!

Jac Mac

|

11-09-2006, 04:06 AM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

Good project Russell,

I'd like to see the rear suspension pickup points brought in a bit and some shorter axles used. I'm not keen on the tyres hanging out of the guards look.

I looked at using the vette transaxle and torque tube but it was too much work to change my chassis to accept it. It would have made maintenence a pain too. Your car will have a more rearward weight bias than most Cobras. Most seem to be near 50:50 or 52 rear 48 front. Th LS1 only weighs about 400 pounds so that will make for even more rearward bias. It should hook up well.

Bill,

The clutch on one of these engines is in the conventional position with the flywheel on the back of the motor.

In my opinion the torque tube setup is safer than a conventional gearbox setup. There's no universal joints just a straight shaft with greek couplings or similar between the engine and gearbox. This is all contained in a sturdy aluminium tube in case something does brake. That's unlikely though because there's no uni joints which are the weak link in a drive shaft. It's also a lot smoother because there's no vibration induced by uni joints changing angle. Therefore it's more efficient.

In a conventional car setup you are far more likely to have a driveshaft failure catastrophic results than a clutch explosion these days. There's no danger of this with a torque tube.

A scatter shield could be very easily incorporated into the tunnel around the bell housing negating the need for a big heavy steel bell housing. This could be done with a balistic blanket or just steel sheet welded into the tunnel area in the right spots. Clutch explosions are a rare thing these days anyway.

Clutch and flywheels have come a long way sinc the days of grey iron flywheels breaking apart at high RPM. Billet steel flywheels are essentially explosion proof and rated to huge RPM. I put an SFI approved billet steel flywheel in mine and it only weighs 15.5 pounds which is about the same as an aluminium flywheel.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

11-09-2006, 11:30 AM

|

|

CC Member

|

|

|

Join Date: Aug 2000

Location: Pinellas Park,

FL

Cobra Make, Engine: built the molds and body composite construction

Posts: 326

|

|

Not Ranked

Not Ranked

C-4 Coilovers

C-4 Coilovers

Coilovers can be used on C-4 suspensions that were setup originally for the transverse leaf spring. Please see the picture. These are a bolt in with only one change needed in the rear. The diameter of the half shaft must be reduced to 3 1/2 inches or less to avoid coilover spring interference. The numbers are Bilstein Shock numbers B36-0228 and B46--0238.

Coilover kits #193117 and #193102 are needed. Call Bilstein,tell them what you want, ask them to GROOVE the shocks for the coilover kits, I think, they charge about $40 for that. They may ask you to get them through one of their dealers, I used someone in Mass., last time I ordered some. Cost is about $600 without the springs. This change over will give you the freedom to change ride height and spring rates easily.

Bill K

|

11-09-2006, 09:00 PM

|

|

CC Member

|

|

|

Join Date: Oct 2006

Cobra Make, Engine:

Posts: 47

|

|

Not Ranked

Not Ranked

We had seen several C4 cobras but we thought we would try to top them with a C5/C6, the trans axle offers an obvious advantage as well as the rear wishbone setup over the 4 bar.

Side note: We just got our first LS7 yesterday, fresh in the crate, I would love to put that in there but then I would have a 57 convertible short a motor and I would have a Cobra with a “427 Side Oiler” LS7 and enough horse power to scare the crap of pro-drivers.

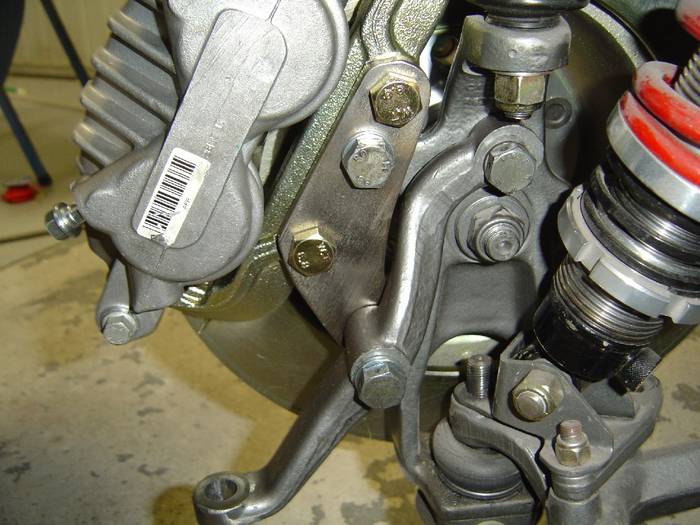

We are still waiting on parts to get back on the cobra but for the guys who have the C4 stuff we made this plate that would let you put the C5 or C6 (including those 6 pistons corvette brakes) and just blot them on this is our 32 we are finishing out the chassis and it will be on the road ASAP. You can see the plates on the passenger side rotor, just bolts on and everything lines up perfectly, cheapest brake up grades on the market for the corvette suspensions.

The only thing I would change on the C4 setup you have is the plate the stock shock mounts to. It’s a thin piece of aluminum not designed to support the weight of the car 100% of the time. We build a heaver pair of brackets to offer a little less flex, you can see them in there as well. And move the shock below the A arm to avoid any adjustment interference. Plus, I like the way it looks better on an open wheeled car. The aluminum plate is only seen on the 84-87 corvette suspension, if memory serves, the later ones, 88-96, have a modified lower A arm to fit the shock to it.

|

11-09-2006, 10:05 PM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

I did something similar to mount thosw big PBR 2 piston calipers onto a Jag front end. The discs are 330mm (13") x 28mm and come from a Holden Special Vehicles, Club Sport. This is a hot version of the current Pontiac GTO you guys get over there.

The bigger discs and PBR calipers are actually lighter than the original Jag XJ6 setup.

Cheers

__________________

Mike Murphy

Melbourne Australia

|

11-14-2006, 02:52 PM

|

|

CC Member

|

|

|

Join Date: Oct 2006

Cobra Make, Engine:

Posts: 47

|

|

Not Ranked

Not Ranked

Off topic but VERY Cool 32

Off topic but VERY Cool 32

This is why we havenít gotten any farther on the Cobra, Paint and body takes way too long but in the long run it's worth it. We don't normally go this far on customers cars but this one is ours. A touch of old school and Modern technology, the home boys down under will like it I think.

It's no Cobra but its still SWEET |

11-14-2006, 03:41 PM

|

|

CC Member

|

|

|

Join Date: Feb 2000

Location: St. Lucia, West Indies,

WI

Cobra Make, Engine: Unique 427SC 383 stroker

Posts: 3,787

|

|

Not Ranked

Not Ranked

That is beautiful. Looking forward to progress on the Cobra.

__________________

Tropical Buzz

Grant me the serenity to accept the things I cannot change, the strength to change the things I can, and the wisdom to know the difference. -(wasn't me)

BEWARE OF THE DOGma!! Dogmatism bites...

|

01-01-2007, 01:15 AM

|

|

CC Member

|

|

|

Join Date: Oct 2006

Cobra Make, Engine:

Posts: 47

|

|

Not Ranked

Not Ranked

Sorry it took so long

Sorry it took so long

Happy New Year to all, I know itís been too long BUT we have the now 23 inch shorter torque tube and we are just waiting on the drive shaft to come back but we wanted to set up the rest of the body so we put it together and wow, I think its going to be fast. Canít think of a better way to use a dead vette thatís for sure.

So to help every ones band width the link under the little photos are the links to the bigger ones give me a few days and I will be posting some more photos.

It also looks like one of our customers who wanted us to put his 2002 vette under a 32 wants the cobra, bad. So I think weíre going to let him have it. More to come

001 Big

001 Big

002 Big

002 Big

003 Big

003 Big

004 Big

004 Big

005 Big

005 Big

And if any one needs a body shoot me an email, my fiberglass guy is getting pissed at me for not keeping him busy during the winter like I did last year. So If any one wants a cobra body with all the fiberglass parts, my cost is $3,800.00 and you can have one for that I just want to keep him happy because I donít want to lay bodies any more itís not fun.

Later

R^3

oh and the roadster is too fast!

Last edited by rat_rod_russell; 01-01-2007 at 10:31 PM..

|

01-03-2007, 10:19 PM

|

|

CC Member

|

|

|

Join Date: Apr 2004

Location: Victoria,

TX

Cobra Make, Engine: FFR MKIII Raodster with Ford BB460 and IRS

Posts: 14

|

|

Not Ranked

Not Ranked

Lookin good Russell, keep up the good work.

|

01-03-2007, 10:46 PM

|

|

CC Member

|

|

|

Join Date: Jul 2005

Location: Bartlett,

Ill

Cobra Make, Engine: Everett-Morrison LS1

Posts: 2,448

|

|

Not Ranked

Not Ranked

Russell

I agree its looking pretty good--however I want to caution you to the fact that your mainframe rails are going to complicate room in the foot box--most of the cars have a dropped floor in the foot box areas and your rails look like they might be 2 x 4 tubes running thru that area-- of course having a nice 4 inch tube down there will make a good pedal mount!!

Keep us up to date

Jerry

|

01-07-2007, 10:41 PM

|

|

CC Member

|

|

|

Join Date: Oct 2006

Cobra Make, Engine:

Posts: 47

|

|

Not Ranked

Not Ranked

I don't have any problems with it. It sits a little lower than most cobras. I'm 6'3" with 34 inch legs and my head sits way below the wind sheild and my feet dont even go all they way to the end of the foot box (I have a size 12 1/2 R foot) that's with that black corvette seat.

R^3

|

01-27-2007, 01:09 AM

|

|

CC Member

|

|

|

Join Date: Oct 2006

Cobra Make, Engine:

Posts: 47

|

|

Not Ranked

Not Ranked

Shelby Cobra Z06, the end to ALL Vettes

Shelby Cobra Z06, the end to ALL Vettes

Bad mouse Bad

Last edited by rat_rod_russell; 01-27-2007 at 01:14 AM..

|

01-27-2007, 01:12 AM

|

|

CC Member

|

|

|

Join Date: Oct 2006

Cobra Make, Engine:

Posts: 47

|

|

Not Ranked

Not Ranked

Shelby Cobra Z06, the end to ALL Vettes

Shelby Cobra Z06, the end to ALL Vettes

I hate Cold weather. I could not go to the shop for 5 days because of the ice

We have been fitting the doors hood and trunk to the cobra and with great ease to our surprise, we have them all in place and tacked in untill we can get some fiberglass weather and set everything in hard.

A few thing have happened during the last few months.

1 my fiberglass guy dropped us he just got a huge order of boats and can't make my stuff any more. So if any one knows of a fiberglass operation in Texas who wants to help make the best fiberglass cobra in the country give them my number.

2 I sold this cobra project to Keith in Arizona as a rolling chassis, He's sending me a dead vette and we'll be putting it under this chassis for him. 2002 LS1, standard brakes, Rack, coils overs, steering, and pedals.

BUT

We also cracked the crate on the LS7 we have for one of our other projects and we will be using it to setup for our Heretic 427 Cobra. and the end of all vette's

But until then here's the hinges and how we built our supports

THE ROD ACROSS THE CENTER IS TEMPORARY UNTIL IT'S GLASSED IN.

Click to make them bigger

Later

R^3

Last edited by rat_rod_russell; 01-27-2007 at 01:15 AM..

|

01-27-2007, 11:54 PM

|

|

CC Member

|

|

|

Join Date: Oct 2006

Cobra Make, Engine:

Posts: 47

|

|

Not Ranked

Not Ranked

The Drive Shaft

Short Little Twerp

|

02-22-2007, 09:12 PM

|

|

CC Member

|

|

|

Join Date: Oct 2006

Cobra Make, Engine:

Posts: 47

|

|

Not Ranked

Not Ranked

took me long enough

took me long enough

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 06:56 AM.

Links monetized by VigLink

|