Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

1 |

2 |

3 |

4 |

5 |

6 |

| 7 |

8 |

9 |

10 |

11 |

12 |

13 |

| 14 |

15 |

16 |

17 |

18 |

19 |

20 |

| 21 |

22 |

23 |

24 |

25 |

26 |

27 |

| 28 |

29 |

30 |

31 |

|

|

|

|

CC Advertisers

CC Advertisers

|

|

05-23-2007, 03:02 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: May 2001

Location: Florence,

AL

Cobra Make, Engine: RCR GT 40 & 1966 Fairlane 390 5 speed

Posts: 4,511

|

|

Not Ranked

Not Ranked

TQ / HP question

TQ / HP question

I've got a torque & HP question for the experts,

I have a 5.0 1996 block with a 354 stroker kit, 3.47" x 4.03" with 5.4 rods, EFI, 90 mm mass air, 70mm TB, 36 lb injectors, dyno tuned & chip, 190cc Pro Comp aluminum heads 2.02 - 1.6, 1.7 roller rockers, 1 5/8" headers, 10.5 - 1 cr.

Comp cam 35-518-8 fw XE274HR-12

gross valve lift int .555 ex .565

duration @ .006 tappet lift 274 in ex 282

valve timing @.006 open close

int 29 BTDC 65 ABDC

ex 77 BBDC 25 ATDC

these specs are for cam installed @108 intake center line

int ex

duration @ .05 224 232

lobe lift .3480 .3540

lobe separation .112

this motor dyno'ed at 323 rwhp & 375 rwtq

Question: why the big different is tq & hp? What controls the rpm range of hp & tq? What would it take to get 375 HP & Tq? I know that several components have an influence on tq & hp but I would like to better understand it.

Thanks

Dwight

__________________

''Life's tough.....it's even tougher if you're stupid.'' ~ John Wayne

"Happiness Is A Belt-Fed Weapon"

life's goal should be; "to be smarter than inanimate objects"

|

05-23-2007, 07:40 AM

|

|

Half-Ass Member

|

|

|

Join Date: Jun 2005

Cobra Make, Engine: ERA #732, 428FE (447 CID), TKO600, Solid Flat Tappet Cam, Tons of Aluminum

Posts: 22,025

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by Dwight

Question: why the big different is tq & hp? What controls the rpm range of hp & tq? What would it take to get 375 HP & Tq? I know that several components have an influence on tq & hp but I would like to better understand it.

|

Torque is everything; HP is torque at a given RPM -- it's just a mathematical computation. If you want to increase your horsepower, either make more torque or make it at a higher RPM. If you want to make more torque, modify your engine (or swap in a different engine -- FE's, for instance, give pretty decent torque  ). Here's a primer on HP & Torque that explains it pretty well: http://vettenet.org/torquehp.html |

05-23-2007, 10:04 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jan 1999

Location: MARKSVILLE,LA.,,

Posts: 3,235

|

|

Not Ranked

Not Ranked

Dwight;

Sounds like you have a pretty nice motor........323 hp at the wheels would be in the neighborhood of 400 hp at the crank,and the torque would similarly be up there also.........

I would not worry about the hp number as you have plenty of torque to get your car moving........

[quote]this motor dyno'ed at 323 rwhp & 375 rwtq

Question: why the big different is tq & hp? What controls the rpm range of hp & tq? What would it take to get 375 HP & Tq? I know that several components have an influence on tq & hp but I would like to better understand it.

Your cylinder head/intake/carb/cam combo dictate your hp and torque more than anything else (IMHO)...

As one ole mechainic told me years ago, torque gets you moving from a dead stop to a certain speed, hp keeps you at that speed once you get there......

Or as Mark Kinser (WoO race car driver) told me after they switched to Mopar power some years ago, torque wins races, hp sells motors...they had just switched to Mopar engines from chevys, for one reason only, the Mopars made more torque and had a flatter,broader torque curve........

My 65 fastback has a 351-W in it, basically a stock motor, running slightly modified factory iron heads (1972 model heads) and a 484 lift/272 duration hydraulic cam in it, making about 325 hp......everyone that has ever driven the car thinks it's at least a 393 stroker under the hood, for one reason only, torque!!!!!!!!!!!!! the thing pulls like a freight train up until about 5500 rpms,runs the quarter mile in the 12.90s just like I drive it on the street and still gets 23 mpg on the highway cruising at 75mph, it does have a 5 speed tremec in it...........I would not change a thing on it, it's a joy to drive and very mild mannered............

Keep what you have and enjoy it and don't worry about the hp numbers..........

David

__________________

DAVID GAGNARD

|

05-23-2007, 02:29 PM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Gore. New Zealand.,

SI

Cobra Make, Engine: DIY Coupe, F/T ,MkIV.

Posts: 808

|

|

Not Ranked

Not Ranked

The combo you have- 354ci, 3.47" stroke/5.4" rod - will always favour low end torque , which is great for street use etc. With the 8.2" deck height you cannot really improve on this without going to an expensive custom piston with a pin height around 0.900" and the chevy 400 rod @ 5.56".

One point on the print out, did they give you a reason for the 'ripple' in both the tq/hp lines in the 5250rpm region , ignition- fuel supply-revlimiter-valve springs-wheelspin ?

Jac Mac

|

05-23-2007, 07:34 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: May 2001

Location: Florence,

AL

Cobra Make, Engine: RCR GT 40 & 1966 Fairlane 390 5 speed

Posts: 4,511

|

|

Not Ranked

Not Ranked

Jac Mac

They did not explain the chart. Because the car would not crank with the Jacobs ignition box, I dyno'ed it with out one, stock distributor and high output coil. Later I bought a Mallory box and installed it. Would not crank. I called Mallory and they said that the chip (SCT) was not compatible with the box but a 6855M was. I ordered the new box, but have not received it. So maybe the ripple is ingition? I hope so. Fuel supply is good, rev set at 6500, value springs are good to 6800, I don't think we had wheel spin, but who knows. If they have a dyno at the LCS I may get it dyno'ed again. I have driven the car about a 100 miles, pulls like a freight train. I'm working 7 days a week and 10 plus hour shifts. Very little time to play with my Cobra.

Thanks for the advice and see ya'll at the LCS.

Please post more replys.

patrickt, Thanks for the link on HP & TQ. I printed it out and will read it during lunch tonight.

Dwight

__________________

''Life's tough.....it's even tougher if you're stupid.'' ~ John Wayne

"Happiness Is A Belt-Fed Weapon"

life's goal should be; "to be smarter than inanimate objects"

|

05-23-2007, 09:19 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: St. Louisville,

Oh

Cobra Make, Engine: A&C 67 427 cobra SB

Posts: 2,445

|

|

Not Ranked

Not Ranked

What I would tell you is that the hp peaks when the torque starts to drop off faster than the rpm is going up. Your torque starts dropping off around 4500 rpm. The torque is dropping off because the air flow through the engine is not able to increase at a 1:1 ratio with the rpms. In other words, the engine is not able to breath as well above 4500. If your torque would stay flat to 5252 rpm then the tq = hp.

Generally if you open the ports, or increase the durration on the cam, you will get better torque at higher rpm, but you will most likely loose tq at lower to mid rpms.

My guess is the intake, mass air, or throttle body is limiting your engine. If not on the intake side, I would look at the exhaust side next.

Honestly the 347 stroker is not an engine that will live a long life at high rpms IMO. I would be happy with what you have. I like the flat tq in the low to mid rpm. Great for the street.

|

05-25-2007, 10:50 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: May 2001

Location: Florence,

AL

Cobra Make, Engine: RCR GT 40 & 1966 Fairlane 390 5 speed

Posts: 4,511

|

|

Not Ranked

Not Ranked

More Questions

More Questions

Olddog

I have a 70mm TB, 90mm Mass air, Holley Systmax upper & lower intake, 190 cfm Pro comp heads.

Will the 70 mm TB support 450 Flywheel HP?

Will the Holley intake support 450HP? I know they advertize 350 hp on a 302. I dyno'ed the old 302 at 305 rwhp with this intake, but I don't know if it will support 450 on the new motor.

The Pro Comp heads are new on the maket and unproved. If they are 190 cfm heads they should work for the 450 HP I'm after.

I have 200 miles on the new motor and it drives great. Lots of low end torque. Easy to take off in 2nd gear. Pulls like a freight train. I'm trying to put 500 miles on it with out rev-ing to 5500 rpms. I had it dyno'ed to 5500 with no miles on it so I could get the chip right. I can tell it will be a screamer from a stop light. The old motor would pull fast to 6250 and I liked that. This motor is a lot different. I'll have to change the way I drive.

Dwight

See ya'll in London

__________________

''Life's tough.....it's even tougher if you're stupid.'' ~ John Wayne

"Happiness Is A Belt-Fed Weapon"

life's goal should be; "to be smarter than inanimate objects"

|

05-26-2007, 06:52 AM

|

|

CC Member

|

|

|

Join Date: Apr 1999

Location: cleveland,

OH

Cobra Make, Engine: CSX4000, 427

Posts: 1,999

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by Dwight

this motor dyno'ed at 323 rwhp & 375 rwtq

Question: why the big different is tq & hp? What controls the rpm range of hp & tq? What would it take to get 375 HP & Tq?

|

Like other people have said before, your combination ( intake, heads, cam, exhaust) does not appear to make alot of torque at higher rpm, and the torque drops off faster than the rpm increases causing an overall decrease in hp as rpm increases at higher rpms where you need to make good torque to have impressive hp numbers.

I would say take it to an accomplished SBF engine builder that has a dyno, and let him give you some suggestions about what changes could be made.

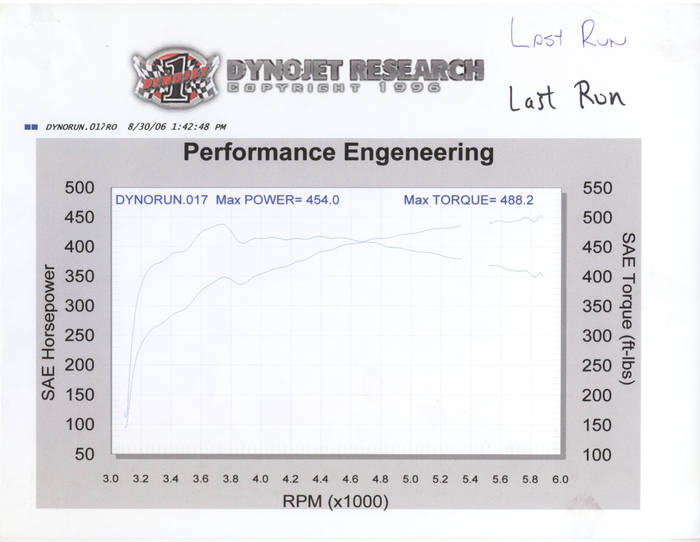

Here is a chassis dyno of my engine, 427 SO, high-riser heads which have much bigger ports than yours, single four dual plane intake, 2" headers. I'm also running a bigger cam, duration 240, 245 or something like that, .670 lift. You see my torque begins to fall off as well, although not at the same rate as yours, with HP still creeping up at 5900 rpms.

__________________

"After jumping into an early lead, Miles pitted for no reason. He let the entire field go by before re-entering the race. The crowd was jumping up and down as he stunned the Chevrolet drivers by easily passing the entire field to finish second behind MacDonald's other team Cobra. The Corvette people were completely demoralized."

|

05-26-2007, 08:37 AM

|

|

Stolen Avitar

|

|

|

Join Date: Oct 2004

Location: Brunswick,

GA

Cobra Make, Engine: BDR 1311 428PI

Posts: 3,044

|

|

Not Ranked

Not Ranked

IMHO Anthony nailed it right on the head. You're running a small cam for the displacement that you have now. This is reflected in your dyno sheet, the poor thing is running out of air. I don't have any experience with your heads, and intake volume (190) is only a small part of what makes the head. Do you have any flow figures for the heads? If they are adequate then a cam swap to something with close to .600 lift and 250 duration @ 50 will wake that puppy right up. Basically you need something to measure on the far side of 5250 rpm!

Steve

|

05-26-2007, 10:18 AM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: St. Louisville,

Oh

Cobra Make, Engine: A&C 67 427 cobra SB

Posts: 2,445

|

|

Not Ranked

Not Ranked

Dwight,

First let me tell you I am not an engine builder with lots of experiance. I have built a few hot chevy and mopars but 30 years ago. I have read a good deal and I have friends that race, so I have always had an interest.

I cannot tell you what 70mm is good for.

Since it is a newer block, I assumed it is a roller cam, not flat tappet. The duration you have, if it is a roller, should pull good torque to 6000 rpm. The same durration in a modular pulls to 7000 rpm, but that is a 4 valve OHC engine. Also your torque does not come up until about 2700 rpm, which tells me there is enough overlap to hurt torque down low. More durration will shift that even further up the scale.

That is why I am thinking your air flow is restricted on the intake or the exhaust side. The 1 5/8" headers may be some of the restriction at the top end. Obviously heads are a huge factor in breathing.

If you are running a flat tappet cam, I could be all wrong. The cam may be the bottle neck.

|

05-26-2007, 10:27 AM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: St. Louisville,

Oh

Cobra Make, Engine: A&C 67 427 cobra SB

Posts: 2,445

|

|

Not Ranked

Not Ranked

PS.

Roller verses flat tappet makes a big differance on how much durration you need. I'm guessing a flat tappet needs 30 - 40 more durration to compare to a roller cam. Maybe a real engine builder will chip in and tell me if I'm close or full of it.

|

05-26-2007, 01:06 PM

|

|

Stolen Avitar

|

|

|

Join Date: Oct 2004

Location: Brunswick,

GA

Cobra Make, Engine: BDR 1311 428PI

Posts: 3,044

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by olddog

Since it is a newer block, I assumed it is a roller cam, not flat tappet. The duration you have, if it is a roller, should pull good torque to 6000 rpm. The same durration in a modular pulls to 7000 rpm, but that is a 4 valve OHC engine. Also your torque does not come up until about 2700 rpm, which tells me there is enough overlap to hurt torque down low. More durration will shift that even further up the scale.

|

I wouldn’t think that the difference here is so much OHV vs. OHC, the largest difference as far as flow requirements go is the displacement, 354 ci for the engine in question and 281 for the mod motor. That 73 cubes can make an enormous difference in camming requirements. Have you tried descktop dyno or anything like that to model other camshaft profiles?

Steve |

05-26-2007, 09:51 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: May 2001

Location: Florence,

AL

Cobra Make, Engine: RCR GT 40 & 1966 Fairlane 390 5 speed

Posts: 4,511

|

|

Not Ranked

Not Ranked

With the 1.7 roller rockers I have .595 lift.

The 96 block is a roller block.

I think I will call Com Cams Tues and see what they say. If I get the right guy maybe they can help.

Thanks for the input and keep it coming. Gives me something to think about.

Dwight

__________________

''Life's tough.....it's even tougher if you're stupid.'' ~ John Wayne

"Happiness Is A Belt-Fed Weapon"

life's goal should be; "to be smarter than inanimate objects"

|

05-26-2007, 10:17 PM

|

|

CC Member

|

|

|

Join Date: May 2006

Location: St. Louisville,

Oh

Cobra Make, Engine: A&C 67 427 cobra SB

Posts: 2,445

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by lovehamr

I wouldn’t think that the difference here is so much OHV vs. OHC, the largest difference as far as flow requirements go is the displacement, 354 ci for the engine in question and 281 for the mod motor. That 73 cubes can make an enormous difference in camming requirements. Have you tried descktop dyno or anything like that to model other camshaft profiles?

Steve

|

Actually the OHC has roller followers that allow a little better ramp rate than a pushrod roller cam. The 4 valve heads flow oh so much better. The little 281 flows more air than the 351W in factory form, even though valve size is limited by the tiny 3.54" bore. |

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 03:23 PM.

Links monetized by VigLink

|