Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

January 2026

January 2026

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

1 |

2 |

3 |

| 4 |

5 |

6 |

7 |

8 |

9 |

10 |

| 11 |

12 |

13 |

14 |

15 |

16 |

17 |

| 18 |

19 |

20 |

21 |

22 |

23 |

24 |

| 25 |

26 |

27 |

28 |

29 |

30 |

31 |

|

CC Advertisers

CC Advertisers

|

|

4Likes 4Likes

12-27-2011, 10:19 AM

|

|

CC Member

|

|

|

Join Date: May 2010

Location: Birmingham,

AL

Cobra Make, Engine: Kirkham 289 FIA, 363 Stroker

Posts: 751

|

|

Not Ranked

Not Ranked

My car functions well as a leaf blower in the driveway and a dust cloud creator when in the garage, even if the floor has just been swept. It's amazing how much air comes out of those pipes when you have a 427FE stroker.

I agree, angle the tips down just a bit. It will make a big difference in db level when you pass by walls, other cars, etc. The pipes look great so far! they are going to look awesome with no welds showing!!!!

I'm doing the same on the mustang exhaust and it is under the car. :O What a PITA. Exhaust fabrication takes forever, when done correctly.

Last edited by RestoCreations; 12-27-2011 at 10:21 AM..

|

-

Advertising

12-27-2011, 07:34 PM

|

|

CC Member

|

|

|

Join Date: Mar 2011

Location: Sleepy Hollow,

IL

Cobra Make, Engine: Kirkham #647 brushed

Posts: 412

|

|

Not Ranked

Not Ranked

|

12-27-2011, 08:31 PM

|

|

CC Member

|

|

|

Join Date: Jun 2008

Location: Chester Springs,

PA

Cobra Make, Engine: Kirkham 289 FIA #690, FRPP 427 Boss engine

Posts: 764

|

|

Not Ranked

Not Ranked

That's so purdy...

__________________

RCR GT40 SOLD to Fast 5

Kirkham #690 289 FIA

|

01-03-2012, 05:44 AM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Lake Havasu City, AZ,

AZ

Cobra Make, Engine: Arps/Burroughs/Hurricane/428FE

Posts: 1,346

|

|

Not Ranked

Not Ranked

Beauitful Beast! It's such a solid car and so cool to look at, can't wait to see it done.

Best of luck, Bill

|

01-05-2012, 07:56 AM

|

|

CC Member

|

|

|

Join Date: Mar 2011

Location: Sleepy Hollow,

IL

Cobra Make, Engine: Kirkham #647 brushed

Posts: 412

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by Bill Bess

Beauitful Beast! It's such a solid car and so cool to look at, can't wait to see it done.

Best of luck, Bill

|

Thanks Bill, I appreciate it  |

01-05-2012, 08:11 AM

|

|

CC Member

|

|

|

Join Date: Mar 2011

Location: Sleepy Hollow,

IL

Cobra Make, Engine: Kirkham #647 brushed

Posts: 412

|

|

Not Ranked

Not Ranked

Some updates,

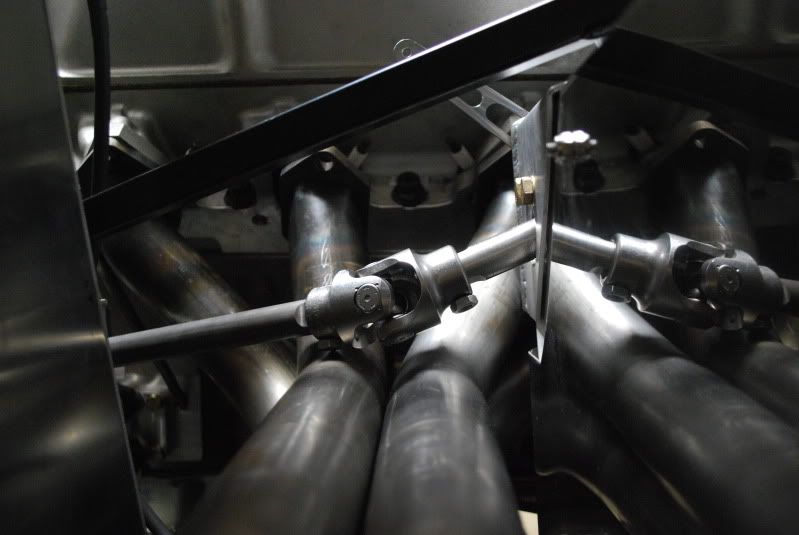

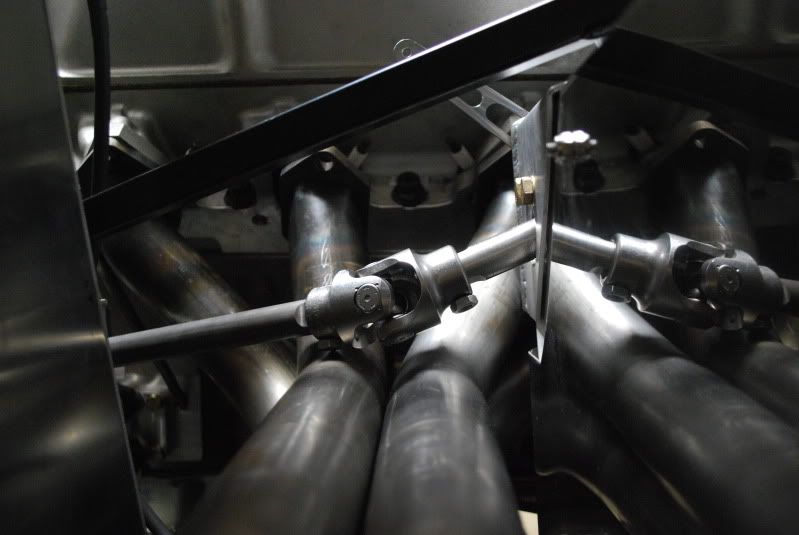

I've been able to work on the car this week and got some stuff done. I wanted to finish the left side pipe but I ran into a problem with the steering cloumn/intermediate steering shaft, hitting the #6 header. Because of that I could not bolt the header on, nor the steering column, and couldn't mock up the pipe.

After a few email back and forth with Kirkham, they found out I got a wrongly sized intermediate shaft, too short by an inch. A new shaft is on it's way here. Thank you to Jeremy at KM for helping me out!

#6 header, which is not bolted, hitting on the steering joint.

About an inch away from being able to bolt it on

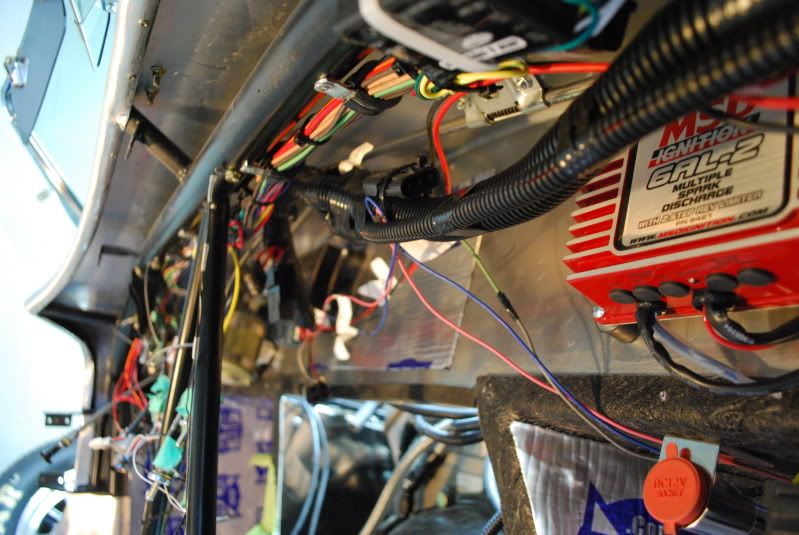

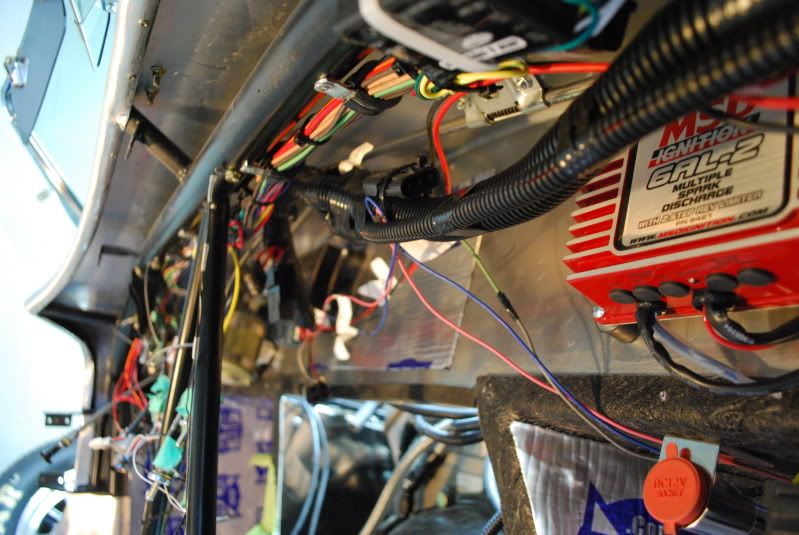

I finished all the wiring this week. Thanks to everybody who helped me out with wiring questions, especially you Mark. So far everything is basically hung up there as I would like to get the car running and see if everything works before making everything look nice. So far all the gauges and basic electrical components work (like the fuel pump, fan, etc...).

I put int the dash last night. Wasn't too hard but it sure is a mess of wires back there, well, not a mess, just a lot of wires. I'm glad I labeled everything beforehand otherwise I would still be working on it! These gauges are really nice. The quality is great and the movements are super smooth (at least on the speedo and tack which sweep at start up).

[img]http://img.photobucket.com/albums/v77/avmaviator/KM647%20Build/DSC_0054.jpg[/

Light up gauges, looks pretty sweet in the dark!

Hope to be giving more updates soon

|

01-05-2012, 08:16 AM

|

|

CC Member

|

|

|

Join Date: Dec 2010

Location: Tempe,AZ-High Point,NC,

AZ

Cobra Make, Engine: Kirkham #684, 482FE, Mike Mccluskey build

Posts: 2,520

|

|

Not Ranked

Not Ranked

Looks very nice, is that a beer bottle in the dash pic, did you get a push button start, looks like the button to the left of the keys.

__________________

PRIDEnJOY

|

01-05-2012, 08:23 AM

|

|

CC Member

|

|

|

Join Date: Jun 2009

Location: Boston,

MA

Cobra Make, Engine:

Posts: 361

|

|

Not Ranked

Not Ranked

sweet dash....i like the color...its simular to the alloy oracle machine  |

01-05-2012, 10:29 AM

|

|

CC Member

|

|

|

Join Date: Jun 2008

Location: Chester Springs,

PA

Cobra Make, Engine: Kirkham 289 FIA #690, FRPP 427 Boss engine

Posts: 764

|

|

Not Ranked

Not Ranked

That looks great, Arnaud! Nice work and that longer shaft should fix you right up.

Just one comment...

...the light's on...

...looks like your battery is not charging...

__________________

RCR GT40 SOLD to Fast 5

Kirkham #690 289 FIA

|

01-05-2012, 10:51 AM

|

|

CC Member

|

|

|

Join Date: Mar 2011

Location: Sleepy Hollow,

IL

Cobra Make, Engine: Kirkham #647 brushed

Posts: 412

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by fordracing65

Looks very nice, is that a beer bottle in the dash pic, did you get a push button start, looks like the button to the left of the keys.

|

It is a bottle, Fat Tire  The button left of the key is the footwell air vent knob.

Quote:

Originally Posted by kgs365

sweet dash....i like the color...its simular to the alloy oracle machine  |

Thanks! It will be similar, but this leather is darker then the Oracle car.

Quote:

Originally Posted by mreid

...looks like your battery is not charging...  |

Must be because the guy who gave me wiring advice doesn't know what he is doing!  |

01-05-2012, 12:22 PM

|

|

CC Member

|

|

|

Join Date: Jun 2008

Location: Chester Springs,

PA

Cobra Make, Engine: Kirkham 289 FIA #690, FRPP 427 Boss engine

Posts: 764

|

|

Not Ranked

Not Ranked

You should be okay, you got your advice before 12:00 when the serious drinking started!

__________________

RCR GT40 SOLD to Fast 5

Kirkham #690 289 FIA

|

01-05-2012, 03:37 PM

|

|

CC Member

|

|

|

Join Date: Dec 2010

Location: Tempe,AZ-High Point,NC,

AZ

Cobra Make, Engine: Kirkham #684, 482FE, Mike Mccluskey build

Posts: 2,520

|

|

Not Ranked

Not Ranked

What a great life, drinking beers, working on a Kirkham, and living in the USA, does it get any better.

__________________

PRIDEnJOY

|

01-05-2012, 04:17 PM

|

|

CC Member

|

|

|

Join Date: Mar 2011

Location: Sleepy Hollow,

IL

Cobra Make, Engine: Kirkham #647 brushed

Posts: 412

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by fordracing65

What a great life, drinking beers, working on a Kirkham, and living in the USA, does it get any better.

|

Amen Pete! |

01-06-2012, 06:55 PM

|

|

CC Member

|

|

|

Join Date: Mar 2011

Location: Sleepy Hollow,

IL

Cobra Make, Engine: Kirkham #647 brushed

Posts: 412

|

|

Not Ranked

Not Ranked

I finished the side pipes today  The weather was amazing (low 50s) and took full advantage of it by working outside, plus it keeps the garage a whole lot cleaner that way. Metal work is awesome but boy it is messy.

They came out pretty well. I need to do a last touch up/clean up, but that will be done before I send them out to get ceramic coated.

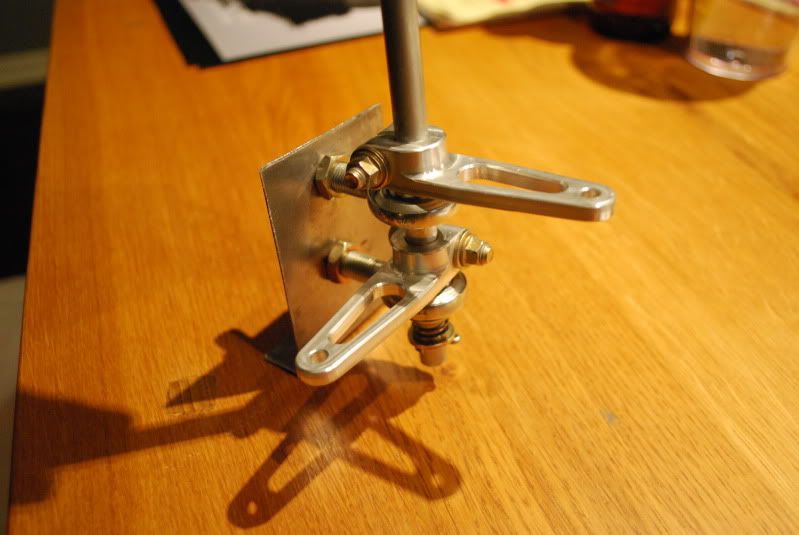

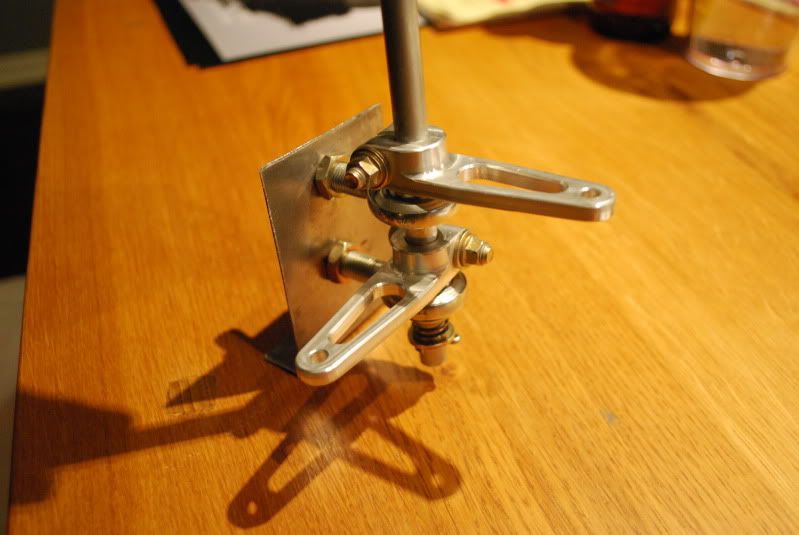

I also worked on figuring out the throttle situation. Once that is solved, I will be ready to start it up, hopefully. The TWM stacks use a cable system instead of the typical push rod set up. I asked a machine shop to make a wheel replicating the cable wheel on the stacks, but he quoted me a few hundreds of dollars... I'm not sure yet if I will go that route or make my own. So I made a prototype of my own tonight. I reused most of the push rod set up components that came with the car. I fab up a basic back plate for mock up, which of course will be changed to a beefy bracket in the future if I go with this set up. So far it doesn't seem too bad. I need to mount it on the car to see if I can realistically use this system. It is pretty fun trying to come up with a solution like that.

We'll see how it goes.

|

01-06-2012, 07:04 PM

|

|

CC Member

|

|

|

Join Date: Jun 2009

Location: Boston,

MA

Cobra Make, Engine:

Posts: 361

|

|

Not Ranked

Not Ranked

i'd have the boys at kirkham billet a piece for you....can't be the only stack set up in a kirkham

|

01-06-2012, 07:33 PM

|

|

CC Member

|

|

|

Join Date: Mar 2011

Location: Sleepy Hollow,

IL

Cobra Make, Engine: Kirkham #647 brushed

Posts: 412

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by kgs365

i'd have the boys at kirkham billet a piece for you....can't be the only stack set up in a kirkham

|

I did ask them about it but they never got back to me. They are pretty busy running their machines for other projects so I understand. Another Kirkham owner, KobraBytes, has the same set up and he built a throttle cable wheel for his car. I contacted him about it and got some info on the specs of that wheel, which in turn I sent to the machine shop. Between all that I am bound to get something done   |

01-07-2012, 03:35 AM

|

|

CC Member

|

|

|

Join Date: Jun 2004

Location: Leicestershire,

UK

Cobra Make, Engine: Kirkham #523, 427 S/O

Posts: 1,137

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by fordracing65

What a great life, drinking beers, working on a Kirkham, and living in the USA, does it get any better.

|

Yes, drinking beer, working on a Kirkham and living in the UK.

We know how to make real beer over here.

Paul |

01-07-2012, 04:46 AM

|

|

CC Member

|

|

|

Join Date: Jun 2009

Location: Boston,

MA

Cobra Make, Engine:

Posts: 361

|

|

Not Ranked

Not Ranked

Ha

Ha

real beer comes in a cold can

Quote:

Originally Posted by FatBoy

Yes, drinking beer, working on a Kirkham and living in the UK.

We know how to make real beer over here.

Paul |

|

01-07-2012, 11:13 AM

|

|

CC Member

|

|

|

Join Date: Jun 2008

Location: Chester Springs,

PA

Cobra Make, Engine: Kirkham 289 FIA #690, FRPP 427 Boss engine

Posts: 764

|

|

Not Ranked

Not Ranked

Hey, Arnaud, let us know when you get the shaft!

heh, heh, heh...I crack myself up!

__________________

RCR GT40 SOLD to Fast 5

Kirkham #690 289 FIA

|

01-07-2012, 11:26 AM

|

|

CC Member

|

|

|

Join Date: Jun 2004

Location: Leicestershire,

UK

Cobra Make, Engine: Kirkham #523, 427 S/O

Posts: 1,137

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by kgs365

real beer comes in a cold can |

Nooooooooo.....

The Kirkham is looking great BTW. I like the dash colour. The Kirkham exhaust collectors are a work of art with beautiful welding and flowing. |

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 02:41 AM.

|

|

4Likes

4Likes

Linear Mode

Linear Mode