Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

| 8 |

9 |

10 |

11 |

12 |

13 |

14 |

| 15 |

16 |

17 |

18 |

19 |

20 |

21 |

| 22 |

23 |

24 |

25 |

26 |

27 |

28 |

|

CC Advertisers

CC Advertisers

|

|

12Likes 12Likes

01-09-2014, 08:11 PM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

Goodbye Kansas

Goodbye Kansas

Last edited by ERA2076; 01-10-2014 at 05:52 PM..

|

01-09-2014, 08:50 PM

|

|

CC Member

|

|

|

Join Date: May 2001

Location: California,

Ca

Cobra Make, Engine: NAF 289 Slabside Early Comp Car with 289 Webers and all the goodies. Cancelling the efforts of several Priuses

Posts: 6,592

|

|

Not Ranked

Not Ranked

?????

__________________

Rick

As you slide down the Banister of Life, may the splinters never be pointing the wrong way

|

01-09-2014, 09:42 PM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

Kansas => Toto, can't get home etc.

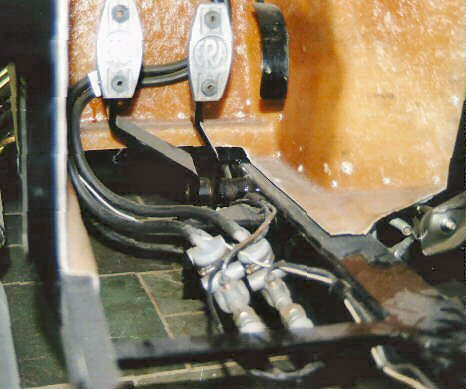

Hole in floor is not normal ERA FIA

Pedal assembly is not ERA Cobra - This is

A sad attempt at humor?  |

01-09-2014, 09:50 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Dec 2007

Cobra Make, Engine: ERA FIA 'Street' Build

Posts: 2,129

|

|

Not Ranked

Not Ranked

No going back ... got it

What exactly is the new set up? |

01-09-2014, 11:27 PM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

Well we are going to fab a plate the size of the square hole we cut out. It will be welded to the top of the frame rail at the middle of the rail and along the bottom of the plate at the rail intersect and gusseted in three locations. The plate will have several holes threaded so we can unbolt the pedal assembly and move them forward and backward. The Tilton set up has a bell crank on the gas pedal. Am looking at moving that to the front of the foot box and devise a longitudinal linkage that can easily be shortened and lengthened as necessary to span between the pedal and the bell crank.

I am short and have small feet and cannot get the cockpit to fit me as I need. I want the seat back close to the roll bar so I can install a head support on the bar. Having the seat close to the rear bulkhead also helps with keeping the belts properly positioned. In order for this to work the pedals need to come forward to the 5 rivets (?) you can see on the floor board. I sat in it tonight with the pedal assembly pulled forward and it was the first time I immediately felt at home. It is still a bit of a crap shoot because the steering column is not installed, but my old seating position left me jammed against the wheel with still some struggle to reach the pedals. Heel and toe with the Tiltons is right there and the pedal faces are all adjustable right to left. I can really dial in a relaxed position.

I am some concerned about the Pedal ratio. Does anyone know the ERA ratio? The Tilton is adjustable from 5.25 to 5.75 and we have it set for 5.75.

Perhaps fab an alum cover that provides for some kind of adjustable heel stop.

Nice thing it is modular.

chr

|

01-12-2014, 06:46 PM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by ERA2076

I am some concerned about the Pedal ratio. Does anyone know the ERA ratio?

|

8.750 from Pedal Pivot to Arm Pivot

1.750 from Arm Pivot CL to Cylinder Rod CL

8.750/1.750 = 5.0

Perfect

chr |

01-12-2014, 07:04 PM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

|

01-21-2014, 03:45 PM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

|

01-10-2014, 12:23 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Dec 2007

Cobra Make, Engine: ERA FIA 'Street' Build

Posts: 2,129

|

|

Not Ranked

Not Ranked

Sounds very clever and looks like it will work and give you some adjustability for fine tuning, good work. Itís very important to feel comfortable, makes for a much more enjoyable and safer driving experience.

Itís interesting the work arounds one comes up with to make the car fit the driver. I have the opposite problem of being too tall for the car. One of the key reasons I went with ERA was their willingness and capability to modify the car to fit me.

Best of luck with your project!

|

01-10-2014, 12:50 AM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

It's interesting the taller guy's in the shop (6 footers) fit it fine. I am 5'6" - all of us in that range struggle.  |

01-10-2014, 09:07 AM

|

|

CC Member

|

|

|

Join Date: Apr 2009

Location: Little Rock area,

AR

Cobra Make, Engine: ERA Street Roadster #782 with 459 cu in FE KC engine, toploader, 3.31

Posts: 4,533

|

|

Not Ranked

Not Ranked

The ERA has a lot of leg room. I'm 6'2" and have my seat set about 1-1/2 inches from the bulkhead and I'm having to move the pedals back as far as they will adjust to comfortably reach them. I want to sit back to have room to manuver by big feet in and out of the door and get away from the windshield. At 5'6" and wanting to sit back in the cockpit I can understand your issue. Good luck with the modifications.

|

01-10-2014, 05:55 PM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

|

01-10-2014, 07:20 PM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

I hope Heaven feels this good.

|

01-10-2014, 08:36 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

You may need a dead pedal to brace yourself when cornering at 1.3g...

__________________

Chas.

|

01-10-2014, 10:30 PM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

I will put the ERA one back in once we have the cockpit sorted.

1.3 - you think it will pull that?

chr

|

01-11-2014, 08:19 AM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by ERA2076

1.3 - you think it will pull that?

|

It better or I'll never read a thread from you again...

__________________

Chas.

|

01-11-2014, 08:54 PM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

1.3 = 458 Italia territory - pretty sure cg is too high, not nearly rigid enough, and are limited by suspension geometry. Still, it will be fun to run it on a pad and see what we get. I will be happy @ 1(+) and that should be achievable.

I will be really happy if I get it to rev limit in 4th, but that is a different problem.

I think your expectation is not reasonable.

chr |

01-12-2014, 09:21 PM

|

|

CC Member

|

|

|

Join Date: Oct 2003

Posts: 4,078

|

|

Not Ranked

Not Ranked

Quote:

Originally Posted by ERA2076

I think your expectation is not reasonable.

chr |

It's called incentive-giving you something to strive for.

With G-7's on you have a shot at it after all that suspension surgery.

Remember, I called Brent's build of Lipton's 482 within 2 HP and yours very close too..

__________________

Chas.

|

01-12-2014, 07:54 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Dec 2007

Cobra Make, Engine: ERA FIA 'Street' Build

Posts: 2,129

|

|

Not Ranked

Not Ranked

You have some very substantial structure for the pedal assembly to bolt on to, nice work. Looks like you are well on the way to getting the pedal assembly just where you want it.

|

01-12-2014, 08:34 PM

|

|

CC Member

|

|

|

Join Date: Sep 2012

Location: Portland,

OR

Cobra Make, Engine: ERA - B2Motorsports Dart 331

Posts: 464

|

|

Not Ranked

Not Ranked

Thanks - maybe a bit over built, but it gives me confidence. The entire assembly including the steel plate is within a couple of pounds of the stock setup. The pedal assembly structure is cast aluminum so what is saved there is given back in a rigid mounting plate.

It would be disastrous to have something break while trying to bring the car down from high speed.

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 07:55 AM.

Links monetized by VigLink

|