Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

| S |

M |

T |

W |

T |

F |

S |

| |

|

|

|

1 |

2 |

3 |

| 4 |

5 |

6 |

7 |

8 |

9 |

10 |

| 11 |

12 |

13 |

14 |

15 |

16 |

17 |

| 18 |

19 |

20 |

21 |

22 |

23 |

24 |

| 25 |

26 |

27 |

28 |

29 |

30 |

31 |

|

CC Advertisers

CC Advertisers

|

|

115Likes 115Likes

09-05-2023, 05:47 AM

|

|

CC Member

|

|

|

Join Date: Feb 2001

Location: Leechburgastain,

PA

Cobra Make, Engine: Myself/Body from CSX-2575 & hand built Birdcage

Posts: 676

|

|

Not Ranked

Not Ranked

Looking great! On the 8.8 real axles, I'm using a Explorer alum 8.8 I don't want to use CV axles I went a different direction I machined down the inner & outer dive stubs cups to a flat with a register & used the 8.8 pinion flange machined to except the flat & register drilled & tapped with grade 8 studs to accept a 4 bolt drive shaft U-joint flange. On the Inner stub same deal bolt on a pinion flange so now i can use a Spicer slip spline drive shaft I found a Jeep front diff drive shaft works perfect they can be cut to any length & have a slip spline. I'll post some pix later.

Pix. https://goo.gl/photos/898aU1K4dZxSTFq89

__________________

6S1941

Allied 289 Slab Side

73 2.3 turbo pinto

Last edited by map; 09-05-2023 at 10:00 AM..

|

09-06-2023, 12:22 PM

|

|

CC Member

|

|

|

Join Date: Mar 2002

Location: Mooresville,

NC

Cobra Make, Engine: Factory Five chassis/Mr. Bruce slabside

Posts: 603

|

|

Not Ranked

Not Ranked

Mike (MAP) an incredibly talented Man.

Mike (MAP) an incredibly talented Man.

Mike, your skill set is just amazing, and thank you and the Brucester for my 289 body.

John O

__________________

jjo42

|

09-12-2023, 07:24 AM

|

|

CC Member

|

|

|

Join Date: Oct 2017

Location: Baysville,

Ont

Cobra Make, Engine: Mine, small block FORD

Posts: 357

|

|

Not Ranked

Not Ranked

Hi Mike!

Great to hear from you again. The last time I checked in on you there was much work going on with your hard top.

I am playing some serious catch up with my posts. Most of the aforementioned figuring and reworking took place back in January/ February according to the picture dates.

Alas, you are jumping ahead in the story my friend

I believe there is an old saying something like..... Two great minds think a like...or is it... Fools seldom differ ? I can never remember

I had better get back to work here and get my next post......posted

.

__________________

Yes, I know,....... but it's mine you see.....

Perhaps he was always a shyster, but we just chose to over look it for awhile.

You build what you like and I will build what I like...it's all good

You know that guy,

The one in the neighborhood who likes to hang around the garage while you are working and talk about back when he had that killer 1977 Chevy Mustang

|

09-18-2023, 09:04 PM

|

|

CC Member

|

|

|

Join Date: Oct 2017

Location: Baysville,

Ont

Cobra Make, Engine: Mine, small block FORD

Posts: 357

|

|

Not Ranked

Not Ranked

Pain in my rear...end

Pain in my rear...end

Hello again all,

So another catch up / update for you. A bit of a long one……..

After the cowl tube rework and pedal box fixes I wanted to keep moving forward. I wanted to deal with the floor but that means I need the seat rails and although I think I know what I am using there I really wanted the seats on hand to test the fit of everything and make decisions.

There are a lot of drawing notes from Chuck that go something like “ spacing to be determined by part used……” or something like that basically I need the parts to be sure they fit. So I ordered some seats and of course need to wait for them.

I still need to do everything else so what next, I turned my gaze to the rear end area.

I have the diff mounts finished so what about the diff?

After my parts gathering and the kindness of friends I have four 8.8 differentials at hand, 3 IRS units and one straight axle with a trac-lok from the mustang that gave its engine and transmission for the build.

One of the IRS units is the alloy case currently in the chassis that had 2.73 gears and an open diff from a Lincoln, another one has an iron case, 3.08 gears and an open diff from the Cougar and the final one has the iron case, 2.73 gears and a trac-lok diff from a friend at work.

A nice collection of parts but what I want is the 3.08 with a trac-lok in IRS form. I am no expert on these things and don’t possess the fancy tools to check and shim these units but I had an idea….

So I started with the 2.73 trac-lok unit and took it apart, and cleaned it, keeping everything sorted out for later.

I discovered the friction packs were not worn out too badly but they were missing some of the tabs on the clutch plates so I need to fix that.

The best deal I found was actually an OEM Ford set on Amazon, go figure  , and it was much cheaper than a budget Dorman branded set from a parts place…hmmmm…go figure that too.

These are obviously an upgrade as the tabs on the clutch plates are now rounded and there is a different stack up recommended with the plates and drive disks, the kit even included the Ford friction modifier for the oil, nice stuff!

So with the Trac-lok back together I disassembled the 3.08 IRS unit enough to remove the diff and its bearings and shims keeping track of everything’s location. I swapped the 3.08 ring onto the trac-lok diff and used the track-lok diff’s bearings and the shims from the 3.08 diff setup and bolted things back together.

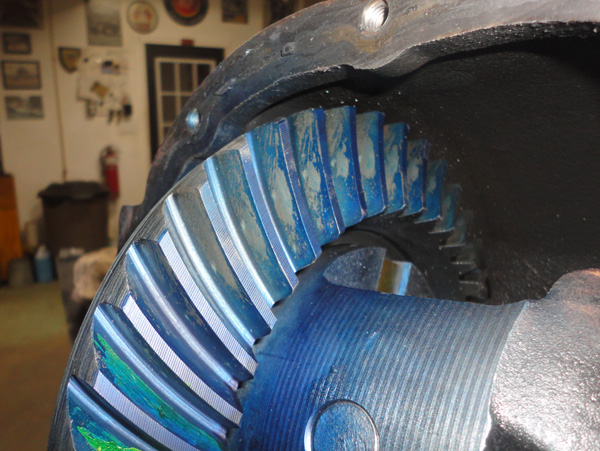

I put some layout blue on the ring and gave it a spin to check the pattern and used my dial indicator to check the backlash, I checked before I took things apart too.

You really need to love mass production and modern machining, the specs I have call for .008 to .012 backlash. When I checked the 3.08 set before I removed it, it was at .009, with the Trac-lok and its bearings in place of the open diff the backlash is now .010”, thanks Ford!

I am happy with that, I am not going to try and change it, it is within the range and the pattern looks good too.

I did not disturb the pinion in the case so that depth is still the same and it’s the same ring gear back in the same case too, so I think this might be a win

I also added a drain hole to the bottom of the case, threaded to use one of the OEM magnetic plugs I have.

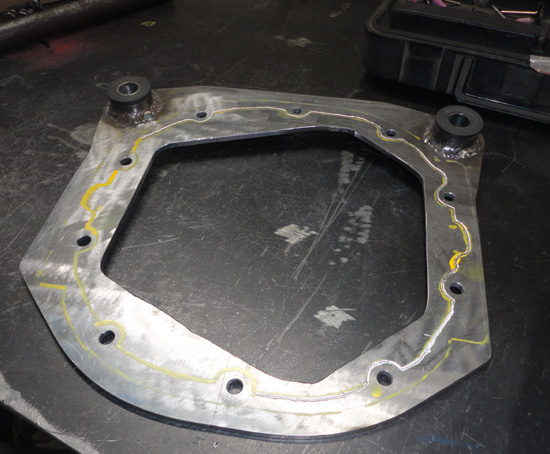

In the end it seems the steel cover is my best choice so I made a bung and welded it in the correct location for filling the diff, it also features one of those OEM magnetic plugs too.

It was time to finish this up so I wanted to seal the mounting plate between the cover and the case, taking a cue from the factory alloy covers I ground a groove around the sealing area on both sides with a ( few) small diamond burr.

Then with everything super clean I applied orange adhesive sealant to both sides and torqued up the bolts. I painted the whole assembly with POR15 ( BTW it doesn’t stick to silicone  ) and installed new seals and mounted it in the chassis. Fits perfectly and looks good to. Fingers crossed everything works in the end…..or rear end!

This all might be a bit long winded but I thought the explaining might help someone else down the road. I certainly spent a lot of time off and on worrying about how I was going to deal with the axles and such I just knew that at some point later I would need to.

Now about those axles

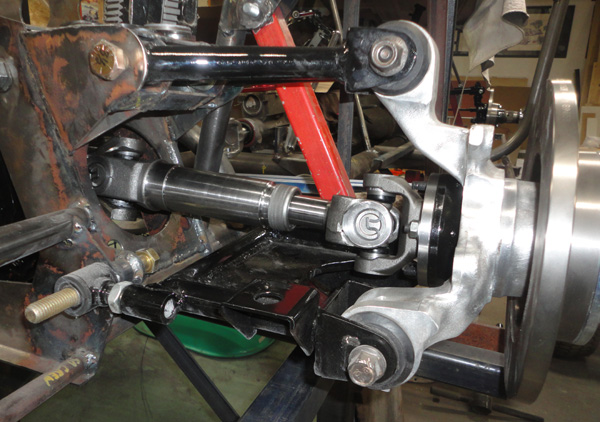

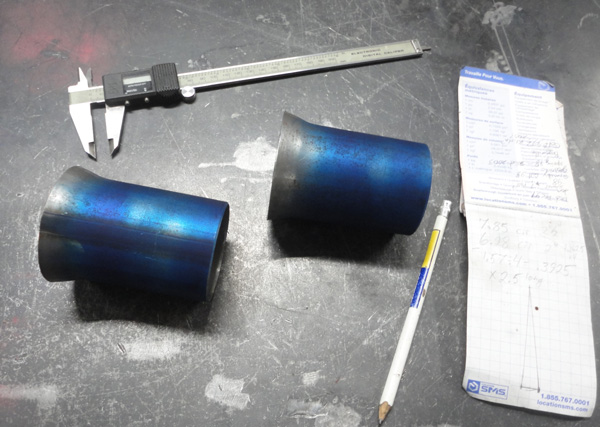

After much reading, thinking and head scratching I had an idea, apparently not an original idea ( I see you Mr. MAP ) but at the time I thought it was, but really is anything an original idea anymore?.

I had measured the original Cougar subframe setup with the adapters and wheels before I took it all apart, then when I had the new design suspension in I measured it again. The stock CV / tripod axles would need to be about 6 inches shorter on each side  . This did not leave much in the middle and a rather stumpy ugly end product.

I read horror stories of splined axles that had been shortened and re splined and then broke off, honestly most likely a case of too much power and poor/ no heat treating. I thought about doing an old school cut and shut with a sleeve or something, even just to get the correct length figured out so Mosher could make me some good ones later.

I found out someone was making 8.8 to Porsche 930 CV stub axles and got to thinking about making adapters of my own.

I found some posts on our site about the original Spicer(?) part numbers AC used and that got me looking at those parts. I had already picked up the yokes to build the driveshaft but there sure are a lot of different yokes, flanges and shafts available, wow!

I recognize the advantages of modern CV joints but the truth is even the mighty 427 Cobras and GT40’s had U joint, sliding spline type axles. Most Grand Prix cars of the 60’s did too, so if it was good enough for them….why not my car?

I took the old Cougar axles I had and sliced off the ends, lots of burning grease smoke and stink, but in the end a splined diff end with a retaining ring and a splined end with a nut for the hub.

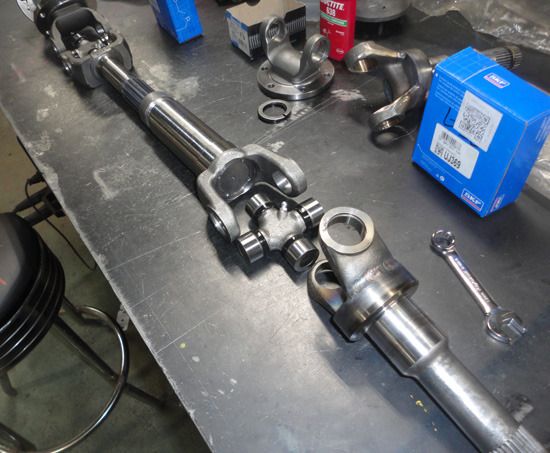

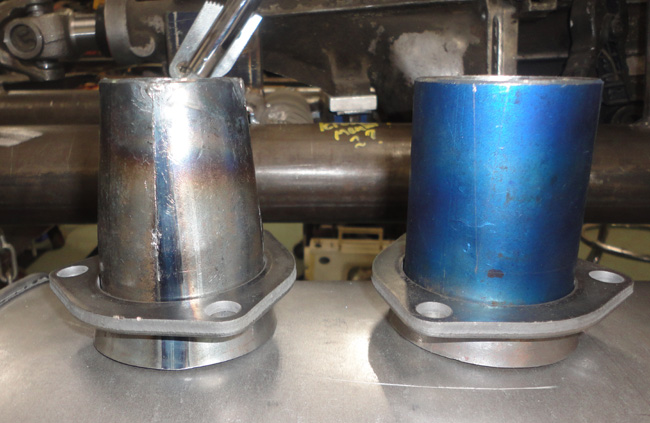

I thought about welding a plate to the inner and machining that for a flange but after I got to measuring and looking at the weld yokes for my drive shaft I figured I could machine the stub to fit a weld yoke and just skip the bolt on yoke part.

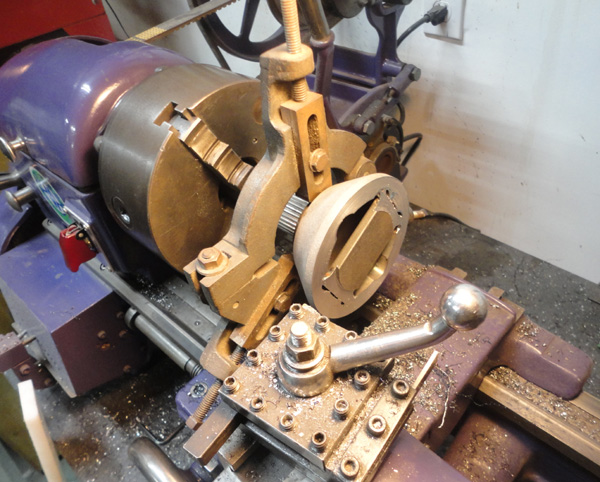

So I tried it out with my classic 1941 Logan lathe, the splined end will not fit in to the headstock all the way. This is the major short coming of the old Logan, the spindle hole is only just over ¾ inch but there are other ways to get this done. I cut off the excess material with a cut off wheel and I have a steady rest for the lathe so I used this to support the stub on the bearing / seal area with the stub as far into the chuck as I could. I just made light cuts and things seemed to go Ok.

For the out board end I set the stub up the same way and tried to face cut it, wow that’s some hard stuff  , honestly I had suspected the CV joint would be hardened for wear resistance. So I annealed them by standing the hub in a pail of water up to the body of the CV to avoid to much heat transferring to the spline area just in case. Then heating the top surface to a nice orange/red color and just letting it cool slowly. Back into the lathe and yes now it can be machined a bit more easily.

So after I had a flat face I added a piece of ¼ steel into the open space and machined it along with the stub to leave a nice little step to center the excellent bolt on yoke I found, I believe it fits Toyota driveshafts but now it fits Ford CV bodies!

The yoke has six 8mm blot holes and the holes do line up very well with the thick areas of the CV between where the balls were so I could drill and tap these for some high strength studs.

In the end I liked what I had done but did not really like the inner stub piece as the Cougar they came from had sat in somebody’s yard for years and there was a corroded area right where the seal contacted the axle, one side was worse than the other but I did not want to chance it and have an annoying little leak so I found a replacement set of axles ( pretty cheap too) and cut the inner stubs off.

It feels fairly strange to take a brand new axle half out of the bag and just lop the end off with a grinder and toss the rest, at least they were cheap.

I machined the inners to fit the yokes and very carefully tig welded them together. The rest was fairly straight forward, assemble the U joints to the yoke parts slip the splines together and ta da! Axles! The best part was installing them; they fit like a glove and look great too!

So while I was in the mood for yokes, U joints and welding I made up the drive shaft too. I cut the tube to length, squared up the ends on the handy old lathe, lined up the yokes and welded that together too. This also fits just fine and all that is left is a trip to the balancing shop for everything at some point in the future.

If nothing else I think an 8.8 can be used in an original style 289 chassis with very few changes and adapters can easily be made for original style axles too.

This all took a lot longer to do than to tell and was also not really done in one continuous process as things had to be figured out then parts had to be ordered and waited for too.

But I thought it best to edit it all into one timeline as I am still playing catch up with my posts.

I hope this meets with your approval Mr. MAP

Next time….out with the bad air…

All the best,

Hudson

.

__________________

Yes, I know,....... but it's mine you see.....

Perhaps he was always a shyster, but we just chose to over look it for awhile.

You build what you like and I will build what I like...it's all good

You know that guy,

The one in the neighborhood who likes to hang around the garage while you are working and talk about back when he had that killer 1977 Chevy Mustang

Last edited by old willy; 09-20-2023 at 12:34 PM..

|

09-19-2023, 05:59 AM

|

|

CC Member

|

|

|

Join Date: Mar 1999

Location: penn.,

Posts: 2,564

|

|

Not Ranked

Not Ranked

part numbers for yokes and slips?

|

09-19-2023, 10:40 AM

|

|

CC Member

|

|

|

Join Date: Oct 2017

Location: Baysville,

Ont

Cobra Make, Engine: Mine, small block FORD

Posts: 357

|

|

Not Ranked

Not Ranked

Hello Mr. Bruce,

No problem sir, I will post the numbers and great supplier I got them from when I get home tonight.

This was also surprisingly inexpensive compared to custom CV axles

I also believe I will have a question for you sir.

__________________

Yes, I know,....... but it's mine you see.....

Perhaps he was always a shyster, but we just chose to over look it for awhile.

You build what you like and I will build what I like...it's all good

You know that guy,

The one in the neighborhood who likes to hang around the garage while you are working and talk about back when he had that killer 1977 Chevy Mustang

|

09-19-2023, 08:01 PM

|

|

CC Member

|

|

|

Join Date: Oct 2017

Location: Baysville,

Ont

Cobra Make, Engine: Mine, small block FORD

Posts: 357

|

|

Not Ranked

Not Ranked

Axle parts

Axle parts

Ok Bruce,

Here they are,

I ordered from an outfit called Driveshaft Parts at www.driveshaftparts.com they had what I was looking for, in stock, with options.

On some of things they seem to have their own house brand stuff as well as the big name brands.

Also they ship to Canada so that was good for me too. I do try and shop local but sadly Canada is a bit of a motorsports desert, perhaps it is our smaller population coupled with a shorter summer season but what it means is it harder and normally much more expensive to get the same items up here

I did take some of these numbers to the local parts store and went weak in the knees when he started giving me prices  so driveshaftparts.com works for me.

BTW, up here in the frozen north I was taught that we don't have Speed shops, we have GREED shops....

OK, enough of my ranting

On the outboard end circular 6 bolt flange 2-2-1339

On the inboard end weld yoke 2-28-417

Outer axle male spline half 2-82-58X

Inner axle female spline half 2-3-5821KX

So obviously 2 of each of those and 4 1310 size U-joints plus your own cut up stock CV axles.

I think the original cars might have used 1330 size joints? but I am not sure. The donor Mustang power train was sporting 1310's on the driveshaft the 95 Cougar was 1330's but it was a tank! So I think these will be fine, we are not running any extreme angles either so that is what I went with.

Check out the website, they have all the specs there too to help you decide.

As for me, Mr. Bruce I am going to need a new hood or at least hood skin for my project, it has a nicely made but so wrong looking 427SC hood currently, I am looking for a regular no scoop hood skin as I intend on bonding it to a more correct looking tube frame. I could also be interested in a USRRC / FIA type if the smooth one is not available.

Can you help me?

Cheers,

Hudson

.

__________________

Yes, I know,....... but it's mine you see.....

Perhaps he was always a shyster, but we just chose to over look it for awhile.

You build what you like and I will build what I like...it's all good

You know that guy,

The one in the neighborhood who likes to hang around the garage while you are working and talk about back when he had that killer 1977 Chevy Mustang

Last edited by old willy; 09-19-2023 at 08:03 PM..

|

09-20-2023, 01:20 AM

|

|

CC Member

|

|

|

Join Date: Mar 1999

Location: penn.,

Posts: 2,564

|

|

Not Ranked

Not Ranked

H man, thanks for the part no's. as for the hood(bonnet ), I have hoods with or without scoops, even got them with louvers, but, and this is the BIG but, iffin' you think the parts prices up there are bad, the shipping of a hood up your way is worse. if you want to investigate further , the box size is approxamately 48" X 50" X6", and weighs about 25lbs with the hood skin in it, thanks, b

|

09-24-2023, 09:22 PM

|

|

CC Member

|

|

|

Join Date: Oct 2017

Location: Baysville,

Ont

Cobra Make, Engine: Mine, small block FORD

Posts: 357

|

|

Not Ranked

Not Ranked

Mr. Bruce,

Thank you for the info on the hood skin,

I will check into shipping options. Everything is expensive these days, but I will need a hood.

I have thought about pulling a partial mold from my existing one and then "removing" the scoop then layup a new skin, hoping I can keep the curves looking ok. But honestly I think getting one of yours might just be a better idea.

__________________

Yes, I know,....... but it's mine you see.....

Perhaps he was always a shyster, but we just chose to over look it for awhile.

You build what you like and I will build what I like...it's all good

You know that guy,

The one in the neighborhood who likes to hang around the garage while you are working and talk about back when he had that killer 1977 Chevy Mustang

|

09-25-2023, 05:52 AM

|

|

CC Member

|

|

|

Join Date: Mar 1999

Location: penn.,

Posts: 2,564

|

|

Not Ranked

Not Ranked

H, check with this outfit, never used them myself but have heard good reviews,- pirateship.com

|

10-10-2023, 08:45 PM

|

|

CC Member

|

|

|

Join Date: Oct 2017

Location: Baysville,

Ont

Cobra Make, Engine: Mine, small block FORD

Posts: 357

|

|

Not Ranked

Not Ranked

A tale of tubing......

A tale of tubing......

Hello again to all.

Well another catch up post here. Again some of this to place over a longer time span as I worked on other things while I waited for parts but I thought it best to just edit this all into one section.

So then “out with the bad air” or an exhausting tale of tubing, or …………

So then,

I have been thinking about the exhaust for quite some time. I originally wanted to go with something like the AC factory cast iron Y type manifolds. Not for their amazing flow capabilities  but for the correct look and compact size, plus I knew they should fit Ok.

Someone on our little corner of the internet here mentioned the Mike McCluskey had a supply of them available. So I called to inquire, left a message and being the nice guy he is he called me right back to tell me that he did not have them anymore he sold the lot to David Kirkham. So I contacted him and after a couple of messages I was told they would see if they had any left to sell and then the line just sort of went dead, no more replies, so I took that as a no. Hey, I understand they want to take care of their main customers just like Superformance, they want to sell cars not parts, it’s just the way it is.

Another line of inquiry got me to Hawk cars in the UK. I was told they could supply them but Oh wow what a price  and then shipping, also from my time on the 289 register it seems they also tend to have some issues with delivering things in a timely manner.

I also considered building some out of precut flanges and heavy wall tubing, it could be done but probably only as a last resort.

I looked at lots of pictures of period correct headers and thought about building something like that. Then I was looking back at some great under hood pictures of CSX2000 when it was sold a few years back and really liked the rough shop made look to the exhaust manifolds on it.

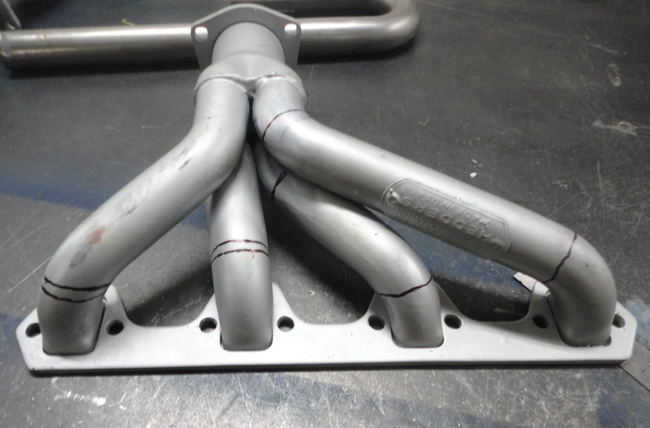

Coincidentally about the same time I came across an excellent deal on a set of Headman block hugger type headers for small block Ford. They were bought for a rod project, painted sliver and never used, the hardware and gaskets were still sealed, Oh, did I mention they were really cheap!

I thought if nothing else they were good parts, flanges, collectors, hardware etc. or they would end up in the collection of parts that I need to pass on to somebody else when this is over.

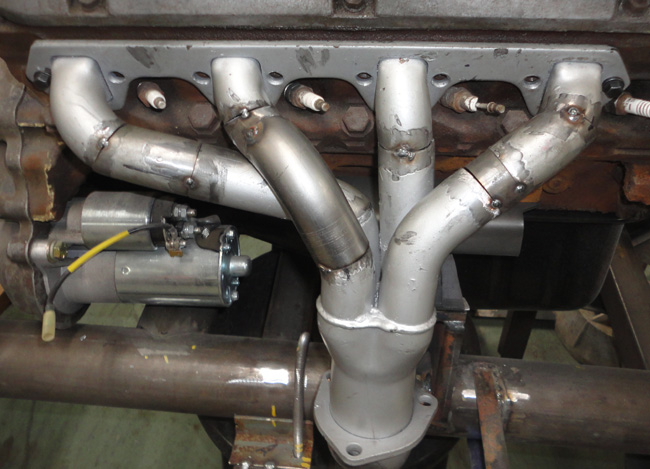

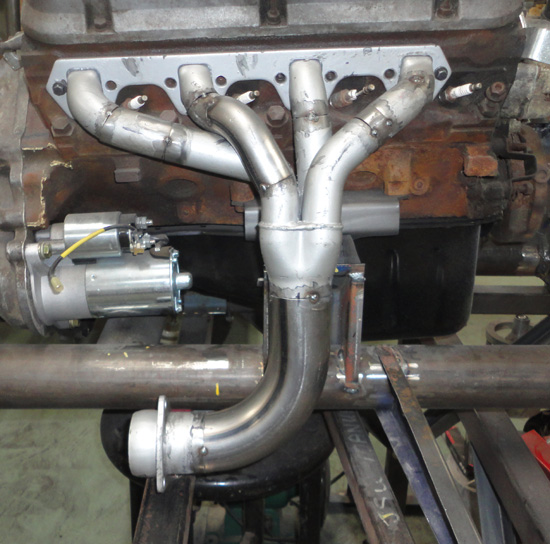

Of course they will not work for our applications, the exhaust must go outside of the chassis tubes not “hug the block” , bit of test fitting made me think differently about how to do this. If I put the right side one on the left and left on the right  It puts the collector in a much better spot. Sort of right in line with the engine mount towers and ahead of the foot boxes, then if I change the angle of the collector to outside the chassis that could work…. maybe

I also decided to swap how the rear primary tube entered the collector moving it from the outside to the inside to give a bit more clearance to the foot box, yes I will be using new space age heat shielding but every bit helps keep those temperatures down.

I also wanted to improve the area where the collector transitions to the exhaust pipes. If I leave the collector as it is I would need to have the tapered attachment flange pipe then immediately a smaller tight 90 bend to turn towards the rear of the car, not so good for flow or clearance around the engine mount area either. So I decided to extend the collector with a full size 90 degree bend and add the mounting flange after that.

I ordered up one U bend for the primary tube reworking and one for after the collector leaving me with this lot of parts.

My original idea had me just making some pie cuts to change the angle but after my decision to swap the rear tube placement there was a lot more cutting leaving only the front 2 tubes still connected for aligning purposes.

And in the end only the second tube was not cut completely apart. After I had the rear tubes sorted and tacked I cut the front tube and inserted a small piece to line things up better. Kind of a mess but they do fit in the space rather nicely.

I then moved on to adding the elbow after the collector and getting the flange where I wanted it. The fit up still looks promising.

So after all that it was time to sit down and do some old school welding. I still enjoy this type of thing; it was the way I first learned way back when.

Also I was always told it is good for exhaust work because it does not tend to get hardened the way a fast electric process like MIG can. It is a slower more controlled way of doing it, adding just as much filler as you need.

My old Henrob / Dillon III torch is still nice to work with as well, I have had it since the early 90’s and it has done a lot of work over the years.

So with them all welded up and the flanges checked and adjusted a bit for straightness I am happy for now. It may not be the most conventional way to build some exhaust but I have hope for them. I am still not sure if I will put the Headman tags back on or not?

They look a bit grotty with the remnants of silver paint and the heat marks from welding but after a quick blast and some high heat paint ( what’s your favorite?) they should do the job just fine. And they certainly have the rough shop made look I liked in CSX2000  . If not there will always be another option….

Also after walking around it for a while I decided I could not abide by my crudely done 1 inch extension of the rear corner tubes and now that other tubes are bracing things I removed the extra tube and angled the rear tube forward to match it. In the end this is under the trunk liner and not seen but the corner tube will visible so better do it now……

I knocked up the rad mounts too…..

So while I was still waiting on seats and things I decided to do the rest of the exhaust

After looking at many options I decided to keep it simple, old school and affordable. So what that really means is I went with 2 inch tubing with classic “cotton reel” type mounts and classic Thrush turbo mufflers.

The last decision was hard, I know the current trend is for the modern chambered exhaust sound but my lovely wife really hates it, one of her requests is that the car is somewhat “quiet”  and I want her to enjoy riding in it so I went with the old school Thrush. We all had them back in the day, I know what they sound like and if we are not happy we can look for other options later but I think they should keep most people involved happy enough.

Also the size was very nice for this under car application; I don’t want too much hanging down.

The tubing came from a great suppler here in Ontario called Lyell’s Stainless Exhaust Inc. they have a nice selection of tubing and bends and everything else you need, they even make their own line of B-52 classic mufflers that I did consider but just went with the pipe, U bends and sleeve type clamps from them. Their pricing is good too!

The mounts were added to one of my Moss Motors orders, cotton reel type ( Jaguar? ) for most of the hangers with a single vertical type in the rear that would fit a classic MGB and others.

So the first step was to take the Headman collector mounts and shrink them down to 2 inch. A bit of math told me the difference in circumferences and I made 4 wedge cuts and tapered the tube with a bit of hammer work over a T bar, looks good so far.

So then I needed to decide where the muffler was going to live and clamped it in place.

I haven’t made any exhaust systems in a long, long time and most of them were a lot shorter (VW’s  ). I bet there are new fancy tools to do this now but I just made up a cardboard template to show me the angle I am looking for in relation to a straight section of pipe and then a template to mark the U bend from.

So once I figure out the angle and mark it I cut it in the handy shop made metal jigsaw and tack it in place and move on to the next one.

I also marked the pieces I made as I went along because I figured the left side of the car should be about the same ……and I was right.

So front pipe…

For the rear pipe I went with the newer (?) style that bends inwards to the main chassis tubes as it passes the rear suspension arms. I know the crude heat bent straight pipes are more period correct but I am not sure how they would work out with my suspension design and they do seem to hang down a lot t. Also they tend to be a bit on the ugly side of the ledger  .

So several bends cut and tack welded later I have a rear exhaust pipe, I then added the mounts, a pair at the front and rear of the muffler, then one on the inside corner of the bend to help with torsion forces and the vertical mount at the rear.

Then I went ahead with the left side and other than a small variation around the pedal box, everything else was a mirror image of the right side, and my markings saved a lot of time.

Then it was time for another classic welding session and reassemble to check the fit.

Everything looks right to me so far, in the future I will blast and paint everything and possibly add the classic chrome tips but perhaps not.

And that’s all for now other than I would like to ask the group…

What is your favorite High heat paint? In the past I have used VHT and Tremclad ? I have been looking at the POR 15 brand stuff but have never tried it, have you?

Let me know your thoughts.

Cheers,

Hudson

.

__________________

Yes, I know,....... but it's mine you see.....

Perhaps he was always a shyster, but we just chose to over look it for awhile.

You build what you like and I will build what I like...it's all good

You know that guy,

The one in the neighborhood who likes to hang around the garage while you are working and talk about back when he had that killer 1977 Chevy Mustang

Last edited by old willy; 10-10-2023 at 08:48 PM..

|

10-11-2023, 06:02 AM

|

|

CC Member

|

|

|

Join Date: Aug 2013

Location: Canandaigua,

NY

Cobra Make, Engine: SPF MKII Riverside Racer FIA

Posts: 2,507

|

|

Not Ranked

Not Ranked

Hudson,

Nice work! Gas-N from the Boston area came out to make the headers for my race car and the 289 Superformance road cars and built the headers in a similar way as you did. They placed the flange against the block and through trial and error made the pipe bends using various short pieces until they fit. This was going to be their template for future sets so that they could use the pipe bender.

If at some point you have to take the engine out of the car after the body is on, when it comes time to put the engine back in you will have to put the headers in before dropping the engine in, as they will not fit in there afterwards due to the forward strut tubes and interference from the steering assembly and pedal box. On my car you can remove the forward strut tubes and so the only header that has to go in before the engine is the driver's side one due to the steering mechanism and pedal box.

Jim

__________________

|

10-15-2023, 03:46 PM

|

|

CC Member

|

|

|

Join Date: Oct 2017

Location: Baysville,

Ont

Cobra Make, Engine: Mine, small block FORD

Posts: 357

|

|

Not Ranked

Not Ranked

Hi Jim,

As always, thank you for you insights on these matters. I have added this to my growing list of things “ not to forget” when reassembling the car. There is certainly going to be an “order of operations” to be followed. So many things that will suddenly just be inaccessible once something else is installed, I am certain many bad words will be uttered along the way

__________________

Yes, I know,....... but it's mine you see.....

Perhaps he was always a shyster, but we just chose to over look it for awhile.

You build what you like and I will build what I like...it's all good

You know that guy,

The one in the neighborhood who likes to hang around the garage while you are working and talk about back when he had that killer 1977 Chevy Mustang

|

01-07-2024, 09:17 PM

|

|

CC Member

|

|

|

Join Date: Oct 2017

Location: Baysville,

Ont

Cobra Make, Engine: Mine, small block FORD

Posts: 357

|

|

Not Ranked

Not Ranked

Happy new year and all that! a quick question too ....

Happy new year and all that! a quick question too ....

Hello all.

Happy New Year!

Merry Christmas too,

if I did not mention it before.

All is well here in the semi-frozen north, and it time for another update.

I am still working on the roadster when I can, but things just seem to be a bit more stressed as of late, long day at work then when I do get home and things squared away, it seems my ambition to wander out to the shop has already wandered off somewhere else, weekends seem to get filled up with other things as well but when the stars do align things are happening

This time around I wanted to mention my radiator, suffice to say I did a lot of looking around, I know the early cars had a 62 Corvette rad and tank so that was one option, there is also a nice reproduction of the later McCord rad available from CSX parts but me being me I looked for the harder option

I read somewhere the Corvette rad is about 17 x 22 inches, I could not find a size on the later rads but knew they were made to fit in the same hole. I did not really want to go with a Corvette rad as I want to use the cast heater switch elbow and the vette rad has a very unique angled lower outlet that I felt would not line up very well.

I did consider modifying one but was not sure how it would go. In my looking around for another suitable donor hoping for something old school with brass tanks I could modify, I discovered a company called Northern Radiator, they sell blank aluminum radiator kits.

I am not the best aluminum welder but I can do it so I ordered what was listed as a 22 x 16 inch rad kit. I went through one of their distributors here in Canada called Truck Parts superstore ( no problems to deal with) and received the pre welded and pressure tested basic radiator unit plus inlet and outlet fittings, filler neck and drain fitting, all for about $300 Canadian dollars.

I also ordered an extra 1 ¾ elbow for the lower outlet.

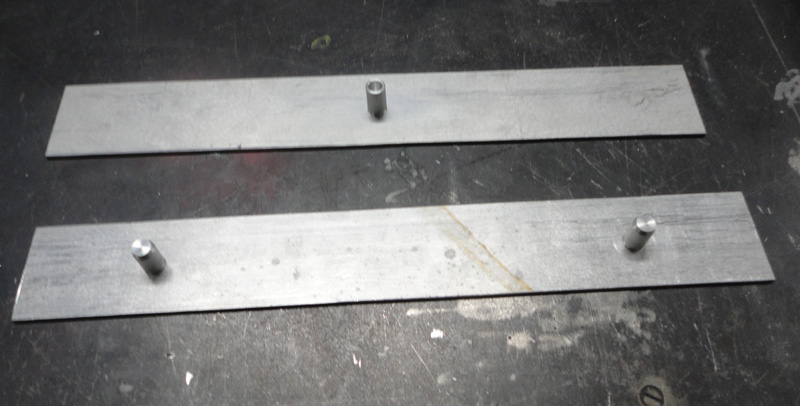

I made up the upper and lower mounts from 1/8th aluminum and turned the “pins” from aluminum rod , I made the upper one appear to be hollow to match the pictures I could find.

I attached ( tig welded) them to the upper and lower core supports and tried the fit.

I needed to adjust the upper mount a bit as I am sure this rad is a slight bit shorter but I don’t think it is to noticeable. I slipped in the lower cast elbow that holds the fan switch and started figuring out the angles.

Turns out I needed to modify the elbow I ordered as it could be smaller and less than 90 degrees.

Then I checked the angle and added the upper hose tube.

Also , with much fussing and test fitting sorted out the lower hose tube to align as best as I can to the cast elbow.

After everything was welded up I plugged the holes and pressure tested the assembly and happily there were no leaks that I could find.

I think the radiator is done for now, However I might change the air bleed from the top of the tank now as I have since changed my mind about a rear mounted puller fan.

From a previous parts order I had the water pump to expansion tank tube, it was not what I wanted as I intend to run a heater so while the welder was set up I decided to try and change that.

I made a tube with a rib and welded it to the existing part and drilled the hole through on the inside, problem solved….. I hope.

I also made a repair to the expansion tank I acquired, the upper bleed hose tube was missing and when I pressure tested it the swaged lower tube was leaking too, so now it’s welded to the tank. But seems I did not take any pictures.

Then while I still had the welder set up I wanted to fix my intake manifold. It’s the classic Edelbrock F4B, apparently a copy or version of the Shelby or Ford label ones.

I picked this up a couple of years ago, a “barn find” I guess, it was used and dirty but in fairly solid shape. There was one odd thing however.

On either side of the plenum there is about a 3/16th hole drilled at a slight downward angle clean through making a fairly large vacuum leak. My best guess is somebody had some sort of cheater nitrous system or was planning on a system.

So I quickly cleaned up the spots and made a couple of plug welds.

I linished the area and then gave the whole manifold a sandblast to blend it all in, looks pretty good in the end so I gave the whole thing a satin clear coat and moved on to something else.

So that’s it for now, work continues and I will post again soon my friends.

However if I could ask anyone who might know……

What is the approximate center to center measurement of the soft top bow ferrules? I am talking about across the cockpit, is it about 48 inches? More, less ?

I am currently working on the cockpit area tubing and need a good reference to compare to my body shape. I know things are wonky there and I am trying to correct it as best as I can.

Thanks folks!

Stay warm,

Hudson

.

__________________

Yes, I know,....... but it's mine you see.....

Perhaps he was always a shyster, but we just chose to over look it for awhile.

You build what you like and I will build what I like...it's all good

You know that guy,

The one in the neighborhood who likes to hang around the garage while you are working and talk about back when he had that killer 1977 Chevy Mustang

Last edited by old willy; 01-07-2024 at 09:24 PM..

|

07-22-2024, 11:11 AM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Mar 2005

Location: Manchester,

NH

Cobra Make, Engine: AK1085 (302 Street), HTM111 (427 Comp), CSX2375R (289 Comp) and COB5999 (427 S/C)

Posts: 19,111

|

|

Not Ranked

Not Ranked

Awesome job!

|

07-22-2024, 01:10 PM

|

|

CC Member

|

|

|

Join Date: Aug 2013

Location: Canandaigua,

NY

Cobra Make, Engine: SPF MKII Riverside Racer FIA

Posts: 2,507

|

|

Not Ranked

Not Ranked

You're getting there Hudson. Once it's all together and registered, you should take it across the border. I know a nice town that you could visit and a winemaker that makes some mighty nice wines.....

__________________

|

07-24-2024, 11:35 PM

|

|

CC Member

|

|

|

Join Date: Jul 2003

Cobra Make, Engine: Unique Motorcars 289 USRRC, 1964 289 stroked to 331, toploader

Posts: 1,132

|

|

Not Ranked

Not Ranked

You have grit, Hudson! Nice progress, and looking good!

__________________

Paul

Unique Motorcars 289 USRRC

1964 289 5-bolt block

Toploader and 3.31 rear

|

08-12-2024, 08:53 PM

|

|

CC Member

|

|

|

Join Date: Oct 2017

Location: Baysville,

Ont

Cobra Make, Engine: Mine, small block FORD

Posts: 357

|

|

Not Ranked

Not Ranked

Time, time time, see what's become of me........

Time, time time, see what's become of me........

Hello all,

Thanks so much for your kind words, work continues but for now I thought I would post another quick update.

A bit of a side project really but still needed.

Awhile back I bought a nice looking Smiths clock for the project, while not 100 percent correct it was much closer looking than what I was seeing in the new Smith’s range.

The seller said / thought it was working and I didn’t really know anything about the inner workings of old Smiths electric dash clocks. I thought, perhaps it would just need a clean and lube and …….

Well it turns out this vintage of Smiths clock is a bit of an orphan. The earlier CE type clocks can be repaired with a new circuit board that some clever fellow is selling to replace a contact point system they had but alas this is the later CTE type and had a strange transistorized pulsing electromagnet type drive that powered a balance wheel set between 2 permanent magnets then driving a cheap plastic clockwork.

From what I read (after the fact  ) they were not very robust and mostly just failed in short order. The laminated balance assembly with the magnet windings falls apart and sadly there really is no fix for that.

So it goes without saying that of course my clock did not work and upon inspection the balance was the issue and honestly I would say I was not the first person to have checked so…  ……

But you don’t know, what you don’t know, I guess. Buyer beware? or advice along those lines...

I figured my best answer was to remove the internals and figure out how to mount the dial and hopefully the hands onto a modern quartz movement and try and make it all fit. I am certainly not the first person to think of this, many old wall and mantle clocks get resurrected this way.

There are a lot of dash clock options available so I found one that looked compact enough, was good quality and was reasonably priced too as it was not going to survive this process either way. I have never heard of KUS brand of gauges before and they seem to be marketed to the marine industry.

It is a well-made item and sealed for marine use, this also means it has a remote mounted button for adjusting the time which I think turned out to be a bonus.

So first I took the old Smiths clock apart, all I really needed was the main case, dial, hands, crystal and knobs.

Then I opened the KUS clock and removed it’s inner workings .

So it is a quartz oscillator type circuit driving a small motor for the hands, the setting is accomplished by somehow driving the motor into hyper speed, whipping the hands around until the time is correct….cool

I cut some scrap styrene to make spacers to support the new drive unit in relation to the dial and then the correct depth in the case, using the same screws that held the old Smiths guts in place. Trust me this was much easier said than done, but it fits.

I was able to resize the Smiths hands to fit the new shafts too to help keep the original look although the KUS hands would have been somewhat OK too.

I made some cut outs to let the light around the dial as the old smiths one did and then found a fairly small momentary contact switch in my electronics junk collection and was able to make the old setting knob function as the new setting button. The old regulation screw was added for looks but that’s all it does now.

So time to test it, I hooked it up to a power supply and let it run for a day.

So happy with that result I gave it a last dusting and closed the case up.

I think in the end it looks pretty good and should be right at home in the dash with the other new Smiths gauges, I guess all their internals have been upgraded over time so why not this one too.

Till next time……..

Hudson

__________________

Yes, I know,....... but it's mine you see.....

Perhaps he was always a shyster, but we just chose to over look it for awhile.

You build what you like and I will build what I like...it's all good

You know that guy,

The one in the neighborhood who likes to hang around the garage while you are working and talk about back when he had that killer 1977 Chevy Mustang

Last edited by old willy; 08-12-2024 at 08:57 PM..

|

08-13-2024, 04:20 AM

|

|

CC Member

|

|

|

Join Date: May 2020

Cobra Make, Engine:

Posts: 93

|

|

Not Ranked

Not Ranked

Your work and skill levels are very impressive, sir.

|

08-13-2024, 04:49 AM

|

|

CC Member

|

|

|

Join Date: Aug 2013

Location: Canandaigua,

NY

Cobra Make, Engine: SPF MKII Riverside Racer FIA

Posts: 2,507

|

|

Not Ranked

Not Ranked

Hudson,

Nice work! Maybe you shouldn't cross the border and come visit. I am afraid that some cobra builder over here in the states will Kidnap you and lock you in a garage having you build cobras all day long.

Jim

__________________

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 10:40 AM.

Links monetized by VigLink

|