Welcome to Club Cobra! The World's largest

non biased Shelby Cobra related site!

- » Representation from nearly all

Cobra/Daytona/GT40 manufacturers

- » Help from all over the world for your

questions

- » Build logs for you and all members

- » Blogs

- » Image Gallery

- » Many thousands of members and nearly 1

million posts!

YES! I want to register an account for free right now!

p.s.: For registered members this ad will NOT show

Main Menu

Main Menu

|

Nevada Classics

Nevada Classics

|

Advertise at CC

Advertise at CC

|

December 2025

December 2025

|

| S |

M |

T |

W |

T |

F |

S |

| |

1 |

2 |

3 |

4 |

5 |

6 |

| 7 |

8 |

9 |

10 |

11 |

12 |

13 |

| 14 |

15 |

16 |

17 |

18 |

19 |

20 |

| 21 |

22 |

23 |

24 |

25 |

26 |

27 |

| 28 |

29 |

30 |

31 |

|

|

|

|

CC Advertisers

CC Advertisers

|

|

02-20-2007, 07:34 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

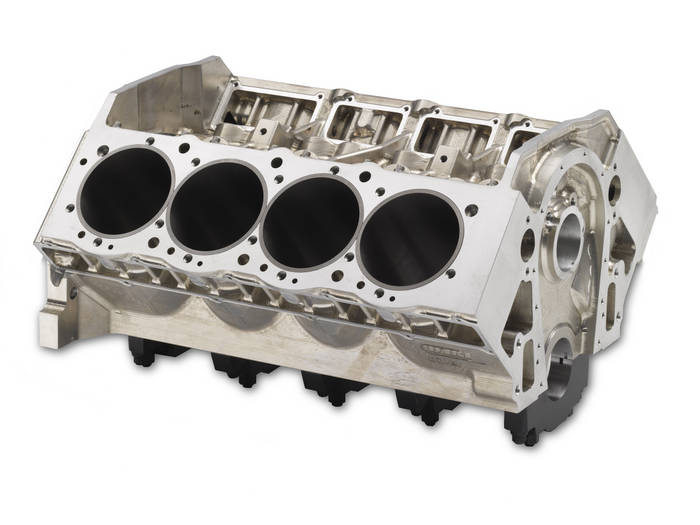

Is that Kieth Black block shown above the type AA fuel dragsters use? I hear they make around 5 or 6000 horse power, ribs might be a good idea!  700-1000 horse? Eh, maybe not so critical

|

-

Advertising

02-20-2007, 07:37 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jan 2001

Location: Santa Barbara, Ca.,

ca

Cobra Make, Engine: R.U.C.C. with a 427FE, toploader

Posts: 1,435

|

|

Not Ranked

Not Ranked

Top end oil?

Top end oil?

David

Very cool block  You said "The block is drilled for hydraulic lifters so it will take either solids or hydraulics." Then you said the rockers will be oiled by the push rods, How dose that happen with a solid lifter? Thanks.

__________________

Mike Z

Nothing sucks more than that moment during an argument when you realize you’re wrong.

|

02-20-2007, 08:21 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2000

Location: Chilliwack,BC,

BC

Cobra Make, Engine: F5 Roadster

Posts: 1,422

|

|

Not Ranked

Not Ranked

Commander

Commander

Please compare apples to apples.

.

A KB block is built to withstand blown alcohol combo's of 3,500 HP and nitromethane combo's upwards of 7,000 HP.

Just how does that have anything to do with a pump gas unblown street engine?

I know of several Honda motorcycle engines with the cylinder coating that have over 100,000 miles on them at 12,000 + rpm sprints with no ill effects.

Great to have big block engines with proven modern technology... keep it up !

Perry.

|

02-20-2007, 09:04 PM

|

|

CC Member

|

|

|

Join Date: Jan 2001

Location: Sunbury,

VIC

Cobra Make, Engine: Rat Rod Racer, LS1 & T56

Posts: 5,391

|

|

Not Ranked

Not Ranked

We were running 250 Production and 125 and 250 GP bikes. I had a Honda NSR250 friends were running Suzuki RGV250s some of the guys were running Yamaha TZ125s and TZ250s. All of these bikes were running coated bores. Prior to that we messed arround with Yamaha RD250 air coolers and water cooled LCs.

I think the first chrome bore I saw was a Kawasaki KDX 175 of about 1980 vintage. The improvement in power and reliability with the chrome bore machines was amazing. 2 strokes can easily generate piston melting exhaust temps. The exhaust port is a hole in the cylinder wall and they usually nip up or pick up the piston on the cylinder wall just below the exhaust port. Since they rely purely on the oil in the fuel to lubricate the cylinder walls the bores get tortured in a 2 stroke.

Most strokers run pretty fat jetting from tha factory for safety but the leaner you get the more power they seem to make up to a point where something melts. water cooling and coated bores let you get closer to that limit. I've seen a few siezed cylinders and the coated cylinder wall still been servicable after a bit of a clean up. Re coating was only ever needed if the surface was gouged or the piston ring had snagged the edge of the coating on the exhaust port.

I think longevity in a 4 cycle engine running coated bores won't be a problem. some of these little 250's were making 80HP at 13K RPM

Cheers

__________________

Mike Murphy

Melbourne Australia

|

02-21-2007, 01:21 AM

|

|

CC Member

|

|

|

Join Date: May 2001

Location: California,

Ca

Cobra Make, Engine: NAF 289 Slabside Early Comp Car with 289 Webers and all the goodies. Cancelling the efforts of several Priuses

Posts: 6,592

|

|

Not Ranked

Not Ranked

Porsche has been using it for a LOOOONNNNGGG time, and we dont need to talk about their reliability at racing speeds do we?

__________________

Rick

As you slide down the Banister of Life, may the splinters never be pointing the wrong way

|

02-21-2007, 05:30 AM

|

|

Banned

|

|

|

Join Date: Jul 2006

Cobra Make, Engine:

Posts: 162

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by Excaliber

Is that Kieth Black block shown above the type AA fuel dragsters use? I hear they make around 5 or 6000 horse power, ribs might be a good idea!  700-1000 horse? Eh, maybe not so critical |

I hear that high-riser sideoilers are over-rated claptrap, especially with the factory 2x4 intakes. Whatever, I don't have one, never had one, and don't particularly want one. So that makes me an expert?

I don't want to argue KB vs TFX vs Arias vs latest NHRA-spec top fuel engines, but notice that I did post that that block pictured was a water block...if you know anything at all you'll know that they don't use hollow blocks in top fuel to make "5 or 6000 horse power".

All I'm saying is that, IF the webbing could be done given the necessary paths the tooling has to follow, it would BE a good idea. Looking at the design, I'm thinking it just isn't possible in a CNC block to leave the webbing there. I object to calling it "moon glow" engineering instead of just admitting that it can't be done and still have the one long water jacket cover in the valley.

For the Kirkham's sake, I worry about the marketing plan: 600 HP max vs the 1500 HP rating of the Shelby block and whatever 1000++ rating the Pond and Genesis blocks are good for. The marketing plan is "it's a little lighter so just get yourself that steel crank", "just don't make too much power"? Don't make too much power, for Cobra owners??????? I don't know about that strategy.

I am waiting to hear the results from the dyno room, which at this stage, are the only results that matter. It's a great effort, I hope it all works as planned.

edit: all these weight comparisons, does the 79 pounds include all the bolts (and all the safety wire) for all of those water jacket covers? Another question, why did Ford abandon its planned use of coating bare aluminum to create a 5.0 l modular? 5.4L details - note the 110 pound weight, with iron sleeves (and all bolts it looks like  ) )

Last edited by Commander; 02-21-2007 at 06:30 AM..

|

02-21-2007, 08:00 AM

|

|

30 Year Wait is Over

|

|

|

Join Date: Feb 2000

Location: London, Canada,

ONT

Cobra Make, Engine: SPF 1630 '70 429 SCJ / 501

Posts: 160

|

|

Not Ranked

Not Ranked

Quick suggestion for the new block.

Don't forget to put the C5AE (or whatever) manufacturing code on the block in the proper spot. This is a replacement block for an original 427. I only suggest this because certain provinces, like Ontario, Canada and States I would assume, use the date code of the block to determine the title year for the ownership of the car. I have a 1970 429 and as such I can title my car as a 1970 SPF. With this date I am exempt from smog requirements.

I know the Pond Motorsports block has this cast in.

__________________

David J. Seed

Q: What makes a good racer?

A: Size 14 shoe, size 2 hat.

Buddy Baker, NASCAR Hero

|

02-21-2007, 10:16 AM

|

|

CC Member

|

|

|

Join Date: Feb 2006

Location: Kimball,

MI

Cobra Make, Engine:

Posts: 110

|

|

Not Ranked

Not Ranked

David,

That is a beautiful piece of work. Are going to you heat treat it?

It looks like an awful lot of chips for under $5000!

Jack

|

02-21-2007, 11:12 AM

|

|

CC Member

|

|

|

Join Date: Mar 1999

Location: Pittsburgh,

PA

Cobra Make, Engine: Midstates, 427FE stroked to 482CI

Posts: 134

|

|

Not Ranked

Not Ranked

The price is actually quite high....IMHO

The price is actually quite high....IMHO

You can buy a brand new 3000 to 4000 pound car for $5 to $15/pound. Even an exotic high performance car would cost about $20 to $30 per pound.

This block alone will cost $62.5 per pound. The aluminum chips left over from the 400 pound blank can be re-meted and re-cast into more blanks. My point is that the leftover chips are not discarded, they have a scrap value.

Aluminum costs about $1.50 per pound for the raw material ready to be machined.

Compare this to a brand new scat crankshaft for an FE. The cranks weighs roughly 70 pounds and sell for $500. Thats only $7.00 per pound for a highly machined/finished product.

|

02-21-2007, 11:42 AM

|

|

CC Member

|

|

|

Join Date: May 2004

Location: Palm Coast,

FL

Cobra Make, Engine: Shelby American CSX 4241 - authentically built

Posts: 2,573

|

|

Not Ranked

Not Ranked

Quote:

|

Originally Posted by Commander

For the Kirkham's sake, I worry about the marketing plan: 600 HP max vs the 1500 HP rating of the Shelby block and whatever 1000++ rating the Pond and Genesis blocks are good for. The marketing plan is "it's a little lighter so just get yourself that steel crank", "just don't make too much power"? Don't make too much power, for Cobra owners??????? I don't know about that strategy.

|

Maybe the Kirkhams should consider offers the block BOTH ways. Coated cylinders for those who want it, and sleeved bores for those who want that. This way you can cater people on both sides of the fence, and have 100% of the people interested buying the product.

__________________

Sal Mennella

CSX 4241, KMP 357 - sold and missed, CSX 4819 - cancelled, FFR 5132 - sold

See my car at CSXinfo.net here >> CSX 4241

|

02-21-2007, 11:47 AM

|

|

CC Member

|

|

|

Join Date: Feb 2004

Cobra Make, Engine: KMP, Keith Craft

Posts: 277

|

|

Not Ranked

Not Ranked

Steve Potts:

Of course we all know you had your tongue planted firmly in your cheek. By your standard, I should have paid about $3000 for my Kirkham. I suspect there would be more than a few takers under your "technology by the pound" theory. Oh, excuse me, I have to go take a picture with my $0.50 Canon digital camera while listening to tunes on my $0.25 iPod.

The K boys are in the forefront of innovation in their niche. And even outside of it, as in the case of the new "Rush." That costs money. Judging by what I got, it's money well spent. The only thing that torques me is having to deal with the urge to upgrade when they do something like this!  Those guys have no mercy.

Way to go, David!

David I.

|

02-21-2007, 12:05 PM

|

|

CC Member

|

|

|

Join Date: Mar 1999

Location: Pittsburgh,

PA

Cobra Make, Engine: Midstates, 427FE stroked to 482CI

Posts: 134

|

|

Not Ranked

Not Ranked

David I:

better check you calculator...your kirkham would be $30 per pound x 2500 pounds...$75000. I dont know where you get $3000???

Its just interesting that some finished goods cost $7/pound and others $60+ per pound. A company can charge whatever they want for their finished goods. I'm just pointing out that the cost of raw materials for these blocks are a drop in the bucket.

|

02-21-2007, 12:24 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

xlr8or,

Thank you for your kind words! I hope lightning doesn't strike this block! Damage can be re-plated quite easily. I don't think scratches will be a problem to repair. The coating is 0.005 thick/side and I know it can be coated thicker than that if needed.

I imagine you could sleeve the block if someone wanted to. But I don't see any advantages to it.

Steve,

The rear main seal leaking problems are usually because the block was not clean on assembly or the cap doesn't line up. I haven't had a rear main seal leak in quite some time. Now, I have seen lots of intake manifolds and valve covers leak. But by and large I think that is mostly a case of the engines not being put together carefully. We are paying very careful attention to the machining of the block to make sure it is right, straight, and square.

That said, some of them do leak despite everyone's best efforts. I guess they are just marking their territory...No Ferrari's allowed!

Ernie,

I am going to pay very close attention to the drain back hole. Good idea!

Commander,

I will treat the ribs in the valley in a later post. I have to run right now and I wanted to reply before the list got too unmanageable. But, it is something we have looked into for a lot of years.

olddog,

I got the idea for aluminum main bearing caps from the Rolls Royce Merlin. Now that is an engine that takes an incredible amount of abuse and HAS to keep running. I figured if they would work in a Merlin, then they could work for us as well. Not to mention, modern engines (including F1 motors) now have aluminum main caps. I have always wondered about the different coefficients of thermal expansion and how that has to play havoc on bearing clearances. That may not be such a problem in a drag motor as the race if over with a few revoloutions of the motor. A street/race motor has time to heat soak and cause problems. Admittedly, I don't know much about drag motors as that isn't our bag. Very few of our customers drag race and those that do obviously don't do it seriously so it is not a priority for us.

Ibr8k4vetts,

My mistake. Originally we were going to drill the oil galley up the head bolt like the original blocks but that caused many problems with the water jackets. We are still trying to get around that problem, but I think we will just stick with the push rod oiling system--ie, no capability for solids for now.

HighPlainesDrifter,

Thank you for your kind words. Currently, we are going to be very happy with 700-800 hp for a street motor.

Aussie Mike,

You are right. We looked extensively into plating and longgevity and we came to the conclusion there wasn't a problem. Now, we just need to prove that on the dyno.

Rick Parker,

If we can make something as nice as Porsche, we will be happy!

Commander,

I will address the rib question shortly (gotta run). But as for your question of different block heights, I am sorry I missed that. It was not intentional. We will not be offering different deck heights. Even though is it CNC and milled from a billet and in theory we could change anything we wanted...

There are over a MILLION pieces of code to make this block. It has over 10,000 different surfaces. For the small market of those who want a taller deck height it is not worth it to us to do the changes.

Thank you all for your comments. It helps us to make a better product!

I will answer more questions when I return,

David

|

02-21-2007, 12:37 PM

|

|

CC Member

|

|

|

Join Date: Sep 2003

Location: Utica, NY,

Posts: 15

|

|

Not Ranked

Not Ranked

David,

I noticed there are no side skirts for main cap cross bolts. The elimination of the skirt material will add to the total weight reduction but at what sacrifice to the of the block?

|

02-21-2007, 12:40 PM

|

|

CC Member

|

|

|

Join Date: Feb 2004

Cobra Make, Engine: KMP, Keith Craft

Posts: 277

|

|

Not Ranked

Not Ranked

Steve P:

Let's see: at your raw material price of $1.50/lb and my vehicle weight of about 2100 lbs give or take, my car comes out at $3150. I'll take a Baker's Dozen!

No more of this. I'm not hijacking David K's excellent thread. Thanks so much to all of you who have contributed very interesting information, especially on the subject of bore lining and plating.

David I.

Last edited by saltytri; 02-21-2007 at 01:53 PM..

|

02-21-2007, 01:06 PM

|

|

Senior Club Cobra Member

|

|

|

Join Date: Jul 2002

Cobra Make, Engine:

Posts: 15,712

|

|

Not Ranked

Not Ranked

Price per pound?  Well thats one way to look at it I guess. Diamonds, wonder what THEY cost per pound?

|

02-21-2007, 02:00 PM

|

|

CC Member

|

|

|

Join Date: Mar 1999

Location: Pittsburgh,

PA

Cobra Make, Engine: Midstates, 427FE stroked to 482CI

Posts: 134

|

|

Not Ranked

Not Ranked

David I:

That's correct...the raw material cost for all of the parts in your car is extremely low...its staggerring.

Lets look at the other end of the spectrum. Car weight of 2500 lbs x $62.50 per pound(which is the cost of the machined FE block). This yields $156,250.

If we could only find a way to eat steel...its only $.030 per pound...that would be much cheaper than a prime fillet at $12.00/lb.

|

02-21-2007, 03:16 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

Commander,

I appreciate your comments. They are certainly worth commenting on and looking into. My brother and I have spent literally hundreds of hours studying engine blocks, theory, etc. We have all sorts of books on engines and how to make them. Incidentally, our favorite bathroom reading material is "Allied Aircraft Piston Engines of World War II" by Graham White, and Sir Harry Ricardo's "The High Speed Internal Combustion Engine." I highly recommend anyone who is interested in engines read both of them--many times. We have spent hours upon hours in museums studying engines, talking to engine builders in all forms of racing, and fortunately, using engines in all sorts of conditions.

My point on the ribs is I think they do nothing to add to the stiffness of the block in the actual application we are interested in. As for 7000 horsepower drag race engines, I readily admit I have no knowledge or interest in them as I seriously doubt anyone will push our engines to much more than 700hp. After spending the day on the track at Miller Motorsports and hearing EVERYONE (including myself) lift before the end of the straight I can assure you no one is using all the horsepower they currently have--and many of our customers only have 500 horsepower engines.

Why do I think the ribs add "nothing"...

Well, I base that on the observations of many, many motors. As I mentioned, the latest Ford 5.4 doesn't have ribs and is capable of 1000 horsepower (more than I need). Perhaps Ford put ribs in later blocks (I don't know, but you mentioned they did) because people were intending to blow them to ridiculous horsepower figures I simply don't intend to achieve. 700 horsepower is enough; 800 horsepower would thrill me as it is a wide margin of safety. (I am not sure why you mentioned I was only interested in 600 horsepower.) I am sorry if you understood me that way--I should have explained things better.

But, the list of engines without ribs is much longer. The Rolls Royce Merlin, and all radial engines of WWII didn't have ribs. Before anyone says that radial engines are a different monster because all pistons push on the same crank journal, remember there are several radial engines that had multiple cylinders in line (albeit twisted to put the other jugs into the air stream.) Finally, one of the greatest race engines of all time, the Porsche 917, produced 1200 horsepower--and it had no ribs...it is a flat (opposed) engine.

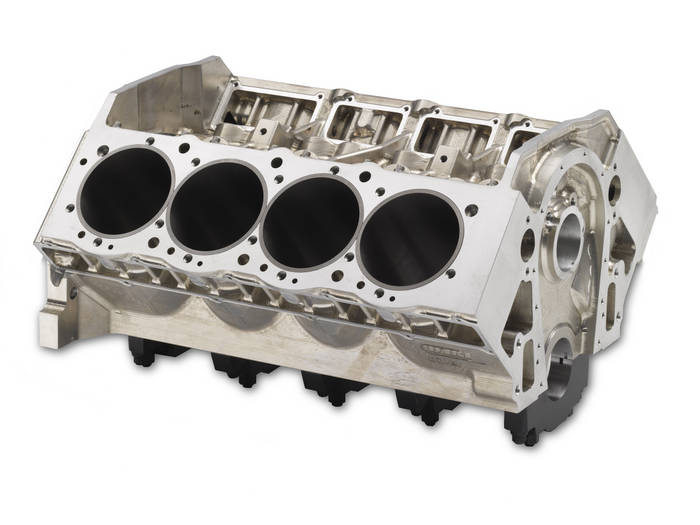

After taking all of those things into consideration, I decided the ribs were insignificant in the overall strength of what I wanted to achieve. the length of the water jacket had nothing to do with the decision. I could have made individual plates between the ribs had I been so inclined. See the picture of the latest DART billet block with ribs and bolt on water jackets. (It made me smile to see both of us come up with the bolt on water jacket independently.)

Here is a picture of DART's latest billet block with individual water jackets around the ribs.

The 79 pounds does not include bolts. (Don't have them yet). But have no fear, I will post everything when we are finished.

As for why Ford doesn't use Nikasil...I can only imagine cost. If they can save 10 dollars on a million item production run they can save 10 million dollars. The guys I know at Ford are concerned with 1/10th of a penny when they are getting bids.

David

|

02-21-2007, 03:39 PM

|

|

Banned

|

|

|

Join Date: Jul 2006

Cobra Make, Engine:

Posts: 162

|

|

Not Ranked

Not Ranked

You do realize you just posted a picture of a (sorta) mainstream (non-7000 HP) block WITH ribs?

I'm sorry this back and forth has seemed to center around the 'rib issue'. I don't care all that much, as long as the actual dyno results show your design to be good. With a solid intake solidly bolted to the heads (not something like a 3 piece kinsler with a non-structural mid-plate), then you're probably OK.

In all seriousness though, I would be interested in one of your wooden blocks. Don't you need to recoup some of that programming and development cost?

|

02-21-2007, 03:41 PM

|

|

CC Member

|

|

|

Join Date: Mar 2001

Location: Provo,

Ut

Cobra Make, Engine: Kirkham, 427

Posts: 6,990

|

|

Not Ranked

Not Ranked

501Cobra,

Good idea! I will look into putting part numbers on the block. You are right, it certainly can be a replacement block.

quickjack,

We had the billet heat treated before we even started. I didn't want the trouble of it warping after it was machined. You are right, by the time you count up the spindle time, I am sure there will be far more parts we make that we will have better margins with.

Steve,

I know you are just joking and it is interesting to look at raw material costs.

Actually, you can not buy aluminum for $1.50/pound. Forgings are more like $3-$5/pound and that does not include the price of tooling. We currently pay $2.25 for extrusion (not forgings) and over $3 for plate--when you can find it. The forging we had made was almost $2000.

Then add:

$125,000 milling machine

$100,000 in tooling, cutter, holders, etc.

$50,000 in CAD/CAM software

200 hours of design time

200 hours of programming

100 hours of proofing--(so far)

and I haven't even paid to turn on the lights yet, paid for opportunity costs, or received a guarantee that it will actually work and people will buy it.

As for material costs, the CAD/CAM programs that I paid $50,000 had a raw material cost of maybe 0.50 cents for the discs they came on.

The raw material costs for the Mona Lisa are probably a dollar.

BUT if you want the "best" raw material cost vs retail cost...

just talk to a lawyer!!!

I know you were just joking, and sometimes I wonder why things cost so much too. I am sure everyone realizes there is WAY more to making something than just the raw material cost of whatever you start with.

David

Last edited by David Kirkham; 02-21-2007 at 04:00 PM..

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -7. The time now is 01:39 AM.

|

|

700-1000 horse? Eh, maybe not so critical

700-1000 horse? Eh, maybe not so critical

Linear Mode

Linear Mode